Exploring the Functionality and Applications of 1% Swing Check Valves in Fluid Systems

Understanding 1% Swing Check Valves Functionality and Applications

A swing check valve is a crucial component in many fluid systems, designed to prevent backflow and ensure the smooth and efficient operation of pipes and machinery. Among different types of valves, the 1% swing check valve stands out for its specific characteristics and uses. In this article, we delve into the functionality, advantages, and applications of the 1% swing check valve in various industries.

What is a Swing Check Valve?

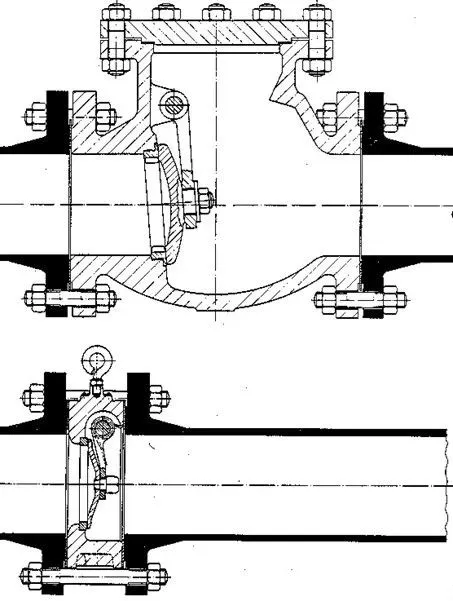

A swing check valve operates on a simple yet effective mechanism it consists of a disc that swings off its seat when fluid flows in the forward direction, and returns to seat when the flow stops or reverses. This design allows fluids to pass through with minimal resistance while preventing backflow, thereby safeguarding the system from potential damages that can arise due to reverse currents.

The term 1% swing check valve refers to a specific design feature whereby the valve allows for a slight tolerance in the opening angle of the disc. In many applications, this 1% variability is crucial as it mitigates the potential of flow turbulence and enhances overall system efficiency.

Advantages of 1% Swing Check Valves

1. Efficiency in Flow Management One of the key benefits of employing a 1% swing check valve is its impact on fluid dynamics. The design helps maintain a smooth flow, reducing cavitation and pressure losses which can occur with other check valve types. This efficiency is critical in settings where maintaining consistent fluid pressure is vital.

2. Durability and Reliability Swing check valves are often manufactured with robust materials such as stainless steel, bronze, or PVC, ensuring they can withstand high-pressure scenarios and corrosive environments. The 1% tolerance adds to the valve's longevity as it minimizes wear and tear over time, reducing the frequency of maintenance and replacements.

3. Ease of Installation and Maintenance The uncomplicated design of swing check valves allows for easy installation and integration into existing piping systems. Additionally, the straightforward mechanism reduces the complexity of maintenance, making it easier for operation teams to handle any issues that may arise.

1 swing check valve

4. Cost-Effectiveness While the initial investment in high-quality check valves may be higher, their durability and efficiency lead to significant cost savings in the long run. By preventing backflow and ensuring a steady flow rate, these valves contribute to overall system efficiency, which can reduce operational costs.

Applications of 1% Swing Check Valves

1. Water and Wastewater Treatment In water treatment facilities, swing check valves are often utilized to manage water flow and prevent back contamination from the discharge side. Their ability to effectively maintain a one-way flow is vital in ensuring the safety and purity of water supplies.

2. Oil and Gas Industries In oil refining and gas distribution networks, maintaining pressure and preventing backflow are critical. 1% swing check valves are employed to safeguard against reverse flow, which could lead to contamination or system failures.

3. Power Generation In power plants, these valves play an essential role in cooling water systems and chemical feed processes, ensuring that flows are regulated and backflow is avoided to maintain operational integrity.

4. HVAC Systems In heating, ventilation, and air conditioning systems, swing check valves help to regulate the flow of refrigerants and water, preventing any adverse backflow that could disrupt system performance.

Conclusion

The 1% swing check valve is a small yet significant component in various industries, capable of enhancing system reliability and operational efficiency. With its robust design, ease of maintenance, and wide range of applications, it has become an indispensable tool in fluid management systems worldwide. Understanding and leveraging the advantages of this valve can lead to improved workflows and reduced operational costs, proving its worth in industrial applications.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025