flanged couplings manufacturers

Flanged Couplings Manufacturers A Detailed Insight

Flanged couplings are an essential component in various mechanical systems, used primarily to connect shafts, ensuring effective power transmission while accommodating misalignment. These couplings are especially prominent in industries such as manufacturing, oil and gas, water treatment, and more. Given their significance, finding reliable flanged couplings manufacturers is crucial for businesses aiming to enhance operational efficiency and maintain system integrity.

Flanged couplings provide a robust solution designed to handle high torque and heavy loads while allowing for a certain degree of movement between connected shafts. Their design typically involves two flanges, which are bolted together, securing the connection firmly. This configuration not only aids in reducing vibration but also makes it easier to install and maintain. For manufacturers, this means the ability to offer a product that combines reliability with ease of use, making flanged couplings a favorable choice in many applications.

When searching for flanged couplings manufacturers, it is important to consider several key factors

1. Quality of Materials The durability and performance of flanged couplings largely depend on the quality of materials used in their construction. Leading manufacturers often utilize high-grade steel, stainless steel, or even specialized alloys that can withstand extreme operational conditions. It is advised to inquire about the materials used and their suitability for the specific application.

2. Manufacturing Standards Reputable flanged couplings manufacturers adhere to international standards such as ISO 9001, which ensures that their products meet consistent quality criteria. Certifications not only indicate a manufacturer's commitment to quality but also assure customers of reliable performance over time.

3. Customization In many industries, standard solutions may not suffice due to varying operational demands. Leading manufacturers often offer customizable flanged couplings to cater to unique specifications, such as dimensions, load capacities, and connection types. This flexibility allows companies to optimize their systems according to specific needs.

flanged couplings manufacturers

4. Technical Support and Expertise A manufacturer that offers comprehensive technical support can greatly benefit customers. From initial design consultations to installation guidance and ongoing maintenance, having access to expert advice can help ensure that flanged couplings perform at their best throughout their operational life.

5. Reputation and Experience Researching a manufacturer’s history, customer reviews, and case studies can provide insight into their reliability and service quality. Renowned manufacturers often have a proven track record of successfully serving a variety of industries, demonstrating their expertise and ability to meet customer needs.

6. Innovation and Technology The manufacturing process for flanged couplings has evolved with advancements in technology. Manufacturers that invest in modern machinery and innovative techniques are likely to produce more precise and reliable products. It's beneficial to choose manufacturers that continually seek to improve their offerings through research and development.

7. Cost and Value While it’s essential to consider price when selecting a manufacturer, it’s equally important to assess the overall value of the product. Cheaper options may compromise on quality and performance, leading to higher costs in the long run due to potential failures or inefficiencies. Analyzing the balance between cost and long-term value can guide buyers towards making informed decisions.

In conclusion, the selection of a flanged couplings manufacturer is a critical aspect of engineering and industrial applications. By focusing on quality materials, adherence to manufacturing standards, customization options, and strong technical support, businesses can ensure they choose the right partner for their needs. With many manufacturers available in the market, investing time in thorough research will pay off, leading to enhanced efficiency and durability in machinery that relies on flanged couplings for operational success.

Implementing such measures not only safeguards investments but also contributes to productive and uninterrupted operations, establishing a solid foundation for future growth and innovation in varied industrial landscapes. Therefore, understanding the dynamics of flanged couplings manufacturers can significantly influence the overall performance and reliability of mechanical systems across multiple sectors.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

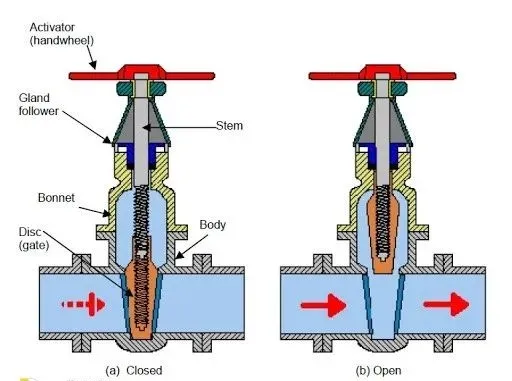

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025