gate valve wheel

Understanding the Gate Valve Wheel A Crucial Component in Fluid Control Systems

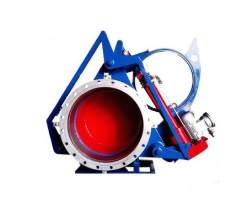

In industrial and municipal settings, the management and control of fluid systems are paramount. One crucial component in this chain is the gate valve, which plays a significant role in regulating the flow of fluids. A critical aspect of the gate valve's functionality lies in the gate valve wheel, a component that may seem simple but is essential for the operation of the valve itself.

What is a Gate Valve?

Before diving into the specifics of the gate valve wheel, it’s essential to understand what a gate valve is. A gate valve is a type of valve that opens by lifting a round or rectangular gate out of the path of the fluid. The primary function of a gate valve is to either fully allow or completely restrict fluid flow; it does not typically regulate flow or pressure. This on-off functionality makes gate valves ideal for applications where the flow needs to be quickly stopped or started.

The Role of the Gate Valve Wheel

The gate valve wheel, often referred to as the handwheel, is a vital part of the valve’s mechanism. It is directly connected to the valve’s stem, which in turn drives the gate up and down. When the wheel is turned clockwise, the gate moves downward, sealing off the flow of fluid. Conversely, turning the wheel counter-clockwise raises the gate, allowing fluid to flow freely through the valve.

The design of the gate valve wheel is critical

. It is generally made from resilient materials like cast iron, brass, or stainless steel, depending on the application and the type of fluid being controlled. The wheel shape is ergonomically designed to allow for easy manual operation, providing a good grip and sufficient torque to operate the valve under varying pressure conditions.Importance of Proper Maintenance

Like any mechanical component, the gate valve wheel requires proper maintenance to ensure its effective operation. Regular inspections are necessary to check for any signs of wear and tear, such as corrosion or mechanical damage. Operators should also ensure that the wheel is adequately lubricated to avoid stiffness during operation, which could lead to excessive force being applied and eventually damaging the valve.

gate valve wheel

Additionally, it's essential to ensure that the valve itself is maintained, as a malfunctioning valve could lead to difficulties in the operation of the wheel. Proper maintenance schedules and practices should be established to keep both the gate valve and its wheel in optimal working condition.

Benefits of Using a Gate Valve Wheel

1. Simplicity and Reliability The straightforward design of the gate valve wheel ensures that it can be operated easily, even in high-pressure situations. Its reliability makes it a favored choice in many industries.

2. Durability Made from sturdy materials, the gate valve wheel is built to last. This durability not only extends the lifespan of the valve itself but also reduces the frequency of needed replacements.

3. Versatility Gate valves with wheels can be adapted for various applications, from water treatment plants to oil and gas pipelines. Their versatility makes them a widely used solution in fluid control systems.

4. Cost-Effectiveness While the initial investment might be higher, the longevity and minimal maintenance needs of gate valves with wheels make them cost-effective in the long run.

Conclusion

In conclusion, while the gate valve wheel may appear to be a basic component of fluid control systems, its importance cannot be overstated. The wheel is integral to the operation of the gate valve, enabling effective management of fluid flow in various applications. Proper understanding and maintenance of this component ensure reliability and efficiency in any system where it is employed. As industries continue to evolve and innovate, the foundational elements, like the gate valve wheel, will remain crucial to the performance of fluid control systems in the future.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025