grooved pipe fitting manufacturers

Understanding the Importance of Grooved Pipe Fittings in Modern Plumbing Systems

In the realm of plumbing and piping systems, the significance of efficient connections cannot be overstated. Among various types of pipe fittings, grooved pipe fittings have emerged as a popular choice for many manufacturers and engineers alike. Their unique design offers numerous advantages, making them ideal for a range of applications.

Grooved pipe fittings utilize a distinctive groove on the ends of the pipes, allowing them to be connected using a simple clamp. This method of connection simplifies the installation process and significantly reduces the overall time and effort required. Unlike traditional welding or threading methods, grooved fittings can be easily assembled without the need for heavy machinery or extensive training. This ease of installation makes them highly appealing for contractors working on large-scale projects, thus simplifying logistics and reducing labor costs.

One of the most notable advantages of grooved pipe fittings is their versatility. These fittings can be made from various materials, including steel, copper, and plastic, catering to the specific needs of different industries. From fire protection systems to HVAC applications, grooved fittings find their utility across various sectors. The ability to adapt to different pipe materials also means that grooved fittings can be used in both new installations and repairs of existing systems.

grooved pipe fitting manufacturers

Durability is another key feature of grooved pipe fittings. The design allows for some movement and flexibility, which is particularly beneficial in areas susceptible to vibration or temperature fluctuations. This flexibility reduces the risk of joint failure, thereby enhancing the longevity of the piping system. Furthermore, many grooved fittings are designed to resist corrosion and other environmental factors, ensuring that they can withstand harsh conditions over time.

Safety is a paramount concern in any plumbing application, and grooved pipe fittings address this issue effectively. The clamp mechanism creates a tight seal that minimizes the risk of leaks. In high-pressure applications, a secure connection is critical to prevent catastrophic failures that can lead to property damage or injury. Grooved fittings provide peace of mind to engineers and project managers, knowing that their systems are not only efficient but also safe.

Additionally, the growth of sustainable and environmentally-conscious practices in manufacturing has led many grooved pipe fitting manufacturers to prioritize eco-friendly materials and production processes. As industries strive to reduce their carbon footprint, using grooved fittings made from recycled materials or designed for easy disassembly aligns with these sustainability goals.

In conclusion, the importance of grooved pipe fittings in modern plumbing cannot be underestimated. Their advantages, including ease of installation, versatility, durability, and safety, make them a preferred choice for manufacturers and contractors alike. As the industry continues to evolve, grooved fittings will likely play an increasingly critical role in the development of efficient and effective piping systems, setting a standard for future innovations in plumbing technology.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

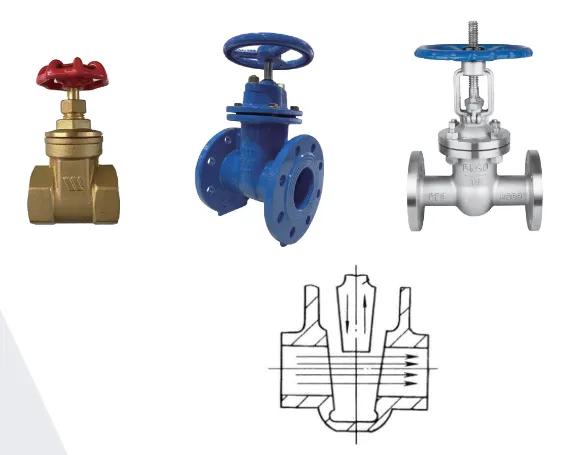

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025