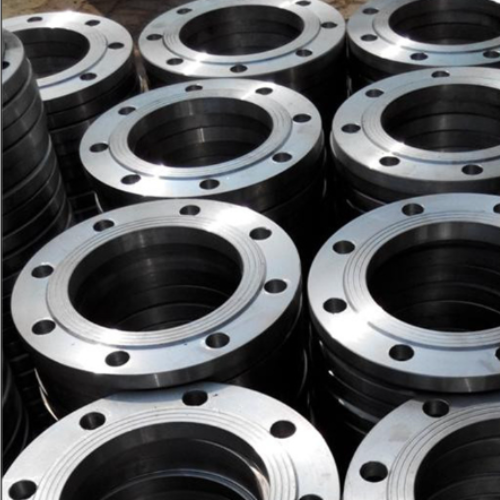

High Quality Slip On Flange for Industrial Piping Solutions

Slip on flange technology plays a crucial role in pipeline connectivity for oil & gas, petrochemical, water works, and metallurgical industries. According to Grand View Research, the global industrial flange market is projected to grow at a CAGR of 5.6% from 2023 to 2028, with stainless steel slip on flange usage increasing due to corrosion-resistant demands.

Innovations in forging processes, tighter tolerances, and automation are pushing flange quality standards. European and Asian manufacturers are increasingly focusing on high-purity alloys (e.g. 316L, 304L) for critical process safety, aligning with ISO 7005-1 and ANSI B16.5 requirements.

| Standard | Material | Pressure Rating (MPa) | Common Sizes (mm) | Corrosion Resistance | Certification |

|---|---|---|---|---|---|

| Gost 12820 | Stainless, Carbon Steel | 0.6 - 2.5 | 15 – 630 | High (SS304/316) | ISO, EAC, GOST-R |

| ANSI B16.5 | Forged Carbon, SS | 1.0 - 6.4 | 15 – 600 | Excellent (316L) | ANSI, ISO 7005-1 |

| EN 1092-1 | Carbon, SS, Alloy | 0.25 - 40 | 10 – 1200 | Very High | CE, PED |

| JIS B2220 | Stainless, Forged | 0.6 – 20 | 15 – 600 | Good | JIS, ISO |

| Type | Material | Pressure (PN) | Design Temp (°C) | Bore (DN, mm) | Surface Finish (µm Ra) | Compliance |

|---|---|---|---|---|---|---|

| Flat Face SORF | SS304/316 | PN10/16/25 | -20 to 400 | 15-400 | 3.2 - 6.3 | ISO, EN |

| Raised Face SORF | Forged Steel | PN16/25/40 | -10 to 450 | 20-600 | 1.6 - 6.3 | ANSI |

| Lap Joint SORF | Carbon Steel | PN6/10 | -10 to 300 | 25-200 | 6.3 | GOST |

| Threaded SORF | Stainless Steel | PN10/16 | -45 to 200 | 15-300 | 3.2 | JIS |

Key industries & benefits:

- Oil & Gas (Upstream/Downstream): Reliable sealing, quick installation, and easy alignment for process piping & manifolds.

- Petrochemical: Stainless steel slip on flange delivers extended corrosion resistance in aggressive media (H2SO4, HCl, NaOH).

- Power Generation: Steam and condensate lines using slip on forged steel flange due to fatigue resistance and pressure cycling stability.

- Water Supply & Wastewater: Large bore slip on pipe flange for economical jointing, maintenance-friendly.

- Metallurgy: Resistance to scaling, temperature shocks, and mechanical stresses.

Technical edge: Slip on flanges are less labor-intensive to install, allowing simultaneous welding both inside and outside the flange hub, enhancing safety against leakage. The flat face (FF) and raised face (RF) designs ensure compatibility with a variety of gaskets, supporting broad media and pressure applications.

Gost 12820 slip on flange production combines drop forging for strength, CNC precision machining for surface finish and dimensioning, and 100% PMI (Positive Material Identification) with NDT (Non-Destructive Testing, e.g., UT/magnetic particle) to ensure ISO 9001:2015 and EN 10204 3.1 compliance.

| Parameter | Range | Test Standard |

|---|---|---|

| Nominal Diameter (DN mm) | 15 ~ 630 | ISO 7005-1, GOST 12820 |

| Pressure (PN, MPa) | 0.6, 1.0, 1.6, 2.5 | EN 1092-1 |

| Material Grade | Q235, 20#, 16Mn, 304, 316L | EN, ASTM, JIS |

| Corrosion Rate (mm/y) | <0.03 (in SS 316L, H2SO4) | ASTM G31 |

| Surface Finish (Ra, μm) | 3.2 - 6.3 | ISO 4288 |

| Welding Thickness | Min. 95% of pipeline | ISO 9606-1 |

| Nondestructive Testing | 100% (Ultrasonic/Magnaflux) | EN 10228-3 |

| Supplier | Main Standard | Min Order (pcs) | Key Certification | Delivery Cycle | Notable Clients |

|---|---|---|---|---|---|

| HBYS Valves | Gost 12820, EN, ANSI | 20 | ISO9001, CE, EAC | 10-17 days | CNNC, Sinopec, TATA Steel |

| ALFA Flanges | ANSI, EN | 30 | API 607, PED | 15-25 days | Saudi Aramco, OMV |

| Metline | DIN, JIS, GOST | 10 | ISO 14001, ISO 9001 | 8-14 days | L&T Hydrocarbon |

| MRC Global | ANSI, MSS-SP | 50 | ISO, FM, UL | 21-35 days | Shell, BASF |

- Material: Carbon steel, stainless steel slip on flange (304, 316L, Duplex), or alloy steels by process/media.

- Facing: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) on demand.

- Surface: Pickling, anti-rust oil, or epoxy coating for aggressive environments.

- Dimensional: Machining within ±0.02 mm; bespoke bolt patterns, tapped holes, or blind execution.

- Documentation: EN 10204 3.1/3.2 mill test certs, NACE MR0175/HIC-resistant material on request.

- Support: Engineering drawings, 3D modeling, MTO (Material Take-Off) and pre-shipment video inspection.

- Delivery: Typical supply cycle 10–17 days (ex-works); urgent orders supported with priority production.

- Quality: Each slip on flange is 100% tested (ultrasound/dimensions/LPI), barcoded for full traceability and packing per ISO 7005/ASTM A182.

- Certification: Mill test certificate EN 10204 3.1/3.2, DNV/Lloyds/SGS third-party inspection, ISO 9001:2015, PED, CE approved.

- Service: 24/7 technical support, remote video QA, after-sales on-site troubleshooting on demand.

- Warranty: 5 years anti-corrosion guarantee for stainless steel and forged flanges.

- Sample policy: Free samples for new customer qualification, global logistics partner.

The slip on flange market continues to expand, propelled by technological innovation, stricter international standards, and widespread applicability across critical sectors. Gost 12820 slip on flange, with its advanced forging process, robust quality controls, and broad material compatibility, offers a cost-effective, reliable, and long-life piping solution—especially for users seeking stainless steel slip on flange or slip on forged steel flange advantages.

Selecting the right flange is not only about the material or standard—it’s about trust: Choose certified manufacturers, demand full traceability, and insist on ISO/EN/ANSI-tested products to maximize safety and uptime.

- Grand View Research. "Industrial Flanges Market Report". https://www.grandviewresearch.com/industry-analysis/flanges-market

- Industry Articles: "Recent Advances on Flange Connection Reliability," Journal of Pressure Vessel Technology. ASME Digital Library

- Piping Engineering Forum: Slip On vs. Weld Neck for Corrosive Duty. eng-tips.com discussion

- HBYS Valves – Certified Flange Offerings: https://www.hbysvalves.com/gost-12820-slip-on-flange.html

- ISO 7005-1, EN 1092-1, ASTM A182, GOST 12820: Piping Standards Documentation.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025