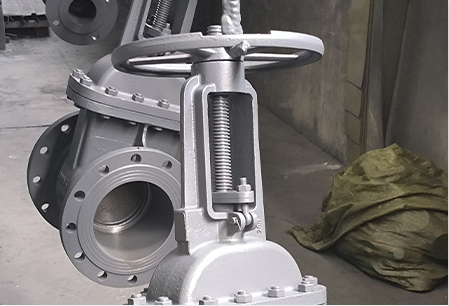

hydraulic check valve manufacturers

Understanding Hydraulic Check Valve Manufacturers

Hydraulic check valves are essential components in fluid power systems, providing safety and efficiency by preventing backflow in hydraulic circuits. As industries continue to evolve and demand for advanced hydraulic systems increases, the role of hydraulic check valve manufacturers becomes increasingly significant. This article delves into what hydraulic check valves are, their importance, and key players in the manufacturing sector.

What Are Hydraulic Check Valves?

A hydraulic check valve is a type of mechanical device that allows fluid to flow in only one direction. It acts as a one-way valve, meaning that when the fluid attempts to flow back in the opposite direction, the valve closes, preventing any reverse flow. This function is crucial in hydraulic systems, where it helps in maintaining pressure, protecting pumps, and ensuring that actuators operate correctly.

Check valves operate using various designs, including ball, poppet, and diaphragm configurations. Each type has its unique advantages and is suited for specific applications. For instance, ball check valves are favored for their low flow resistance, while spring-loaded poppet valves are often used in applications requiring quick response times.

Importance of Hydraulic Check Valve Manufacturers

The significance of hydraulic check valve manufacturers cannot be overstated. They serve multiple industries, including construction, automotive, aerospace, and manufacturing, providing components that enhance the reliability and efficiency of hydraulic systems. Here are a few reasons why manufacturers play a critical role

1. Quality Assurance Reputable manufacturers ensure that their products meet stringent quality standards. This includes utilizing high-quality materials, advanced manufacturing techniques, and performing rigorous testing. Quality check valves contribute to the longevity and reliability of hydraulic systems.

hydraulic check valve manufacturers

2. Innovation The technological advancements in hydraulic systems have spurred innovation among manufacturers. They continually strive to design check valves that are more efficient, easier to install, and capable of handling higher pressures. Innovations include electronic check valves that offer enhanced control and integration into smart hydraulic systems.

3. Customization Different industries have varying requirements, and manufacturers recognize the need for customized solutions. Many offer bespoke designs tailored to specific pressure ratings, sizes, and flow characteristics to meet customer needs.

4. Sustainability As industries increasingly focus on sustainability and environmentally-friendly practices, manufacturers are also adapting their operations. This includes using recyclable materials, reducing waste during production, and developing valves that support energy efficiency.

Key Manufacturers in the Industry

The hydraulic check valve manufacturing sector features several well-established companies known for their high-quality products. Among these, brands like Parker Hannifin, Bosch Rexroth, and Eaton stand out. Each of these manufacturers has built a reputation for reliability, innovation, and customer service.

Parker Hannifin, for example, not only manufactures hydraulic check valves but also offers a comprehensive range of fluid power solutions tailored for various industries. Bosch Rexroth is renowned for its expertise in drive and control technologies, offering a wide array of hydraulic components, including check valves, that are integral to modern machinery. Eaton's commitment to sustainability and energy-efficient solutions has positioned it as a leader in hydraulic systems.

Conclusion

Hydraulic check valves are vital for the optimal functioning of hydraulic systems, and the role of manufacturers in producing quality, innovative, and customized solutions is indispensable. As the demand for efficient hydraulic systems grows, manufacturers will continue to advance technology, ensuring that their products meet the needs of diverse industries. By emphasizing quality, sustainability, and customer focus, these manufacturers play a crucial role in the ongoing development of hydraulic technology.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025