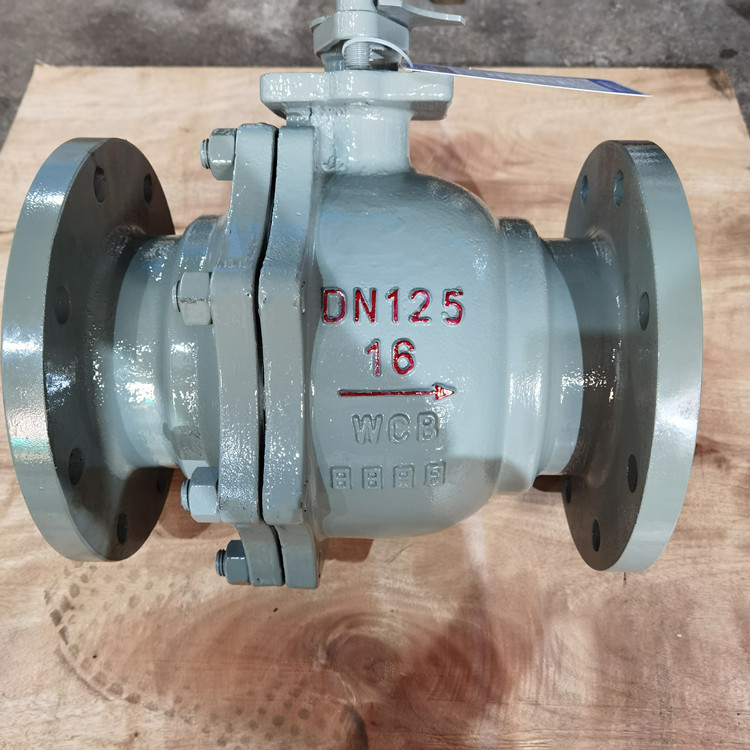

low pressure ball float valve

The Low Pressure Ball Float Valve An Essential Component in Fluid Control Systems

In various industrial and residential applications, effective fluid management is crucial for the smooth operation of systems. Among the numerous devices available for this purpose, the low pressure ball float valve stands out as a reliable and efficient solution. This article explores the design, functionality, advantages, and applications of low pressure ball float valves.

Design and Functionality

A low pressure ball float valve is designed to control the flow of liquids in a system by utilizing the principles of buoyancy. The key components of this valve include a float, a ball, and a valve seat. The float, typically made from a buoyant material, rises and falls in response to the liquid level in a tank or reservoir. Connected to the float is a rod or lever that operates the ball mechanism.

When the liquid level drops, the float descends, allowing the ball to release the opening and enabling liquid flow into the tank. Conversely, when the liquid level rises, the float ascends, pressing the ball against the valve seat, sealing the opening and stopping the flow. This simple yet effective mechanism ensures precise control over fluid levels, preventing overflow and ensuring efficient operation.

Advantages of Low Pressure Ball Float Valves

1. Simplicity and Reliability The design of low pressure ball float valves is straightforward. Fewer moving parts mean less wear and tear, resulting in a longer lifespan and lower maintenance needs. This reliability makes them a preferred choice in many applications.

2. Cost-Effective Solution With their durability and low maintenance requirements, low pressure ball float valves offer an economical solution for fluid control. They reduce the need for frequent replacements, contributing to lower overall operational costs.

3. Versatility These valves can be used in various applications, including water tanks, reservoirs, and irrigation systems. Their ability to adapt to different settings makes them valuable in both residential and commercial sectors.

low pressure ball float valve

4. Precision Control Low pressure ball float valves allow for precise control of liquid levels, ensuring systems operate within desired parameters. This can prevent issues such as overflows or dry running pumps, which can lead to system failure.

Applications

Low pressure ball float valves are utilized in a wide range of applications

- Water Supply Systems In municipal water supply systems, these valves help maintain consistent water levels in storage tanks, ensuring an uninterrupted supply.

- Commercial and Agricultural Irrigation Farmers and commercial growers use these valves to manage irrigation systems efficiently, preventing water wastage while ensuring crops receive adequate moisture.

- Aquatic Systems In fish farms and aquariums, low pressure ball float valves are crucial for maintaining water levels, contributing to the health of aquatic life.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves ensure optimal fluid levels in cooling towers and boilers, enhancing energy efficiency.

Conclusion

The low pressure ball float valve is an indispensable component in fluid control systems across various industries. Its simple design, reliability, and cost-effectiveness make it an attractive option for managing liquid levels. As the demand for efficient fluid management continues to grow, the importance of devices like the low pressure ball float valve cannot be overstated. Whether in residential water systems, agricultural irrigation, or industrial applications, these valves play a pivotal role in ensuring the efficient and effective management of water and other liquids. In an era where resource conservation is paramount, investing in reliable fluid control solutions like the low pressure ball float valve is not just practical; it is essential for sustainable operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025