low pressure check valves

Understanding Low Pressure Check Valves A Comprehensive Overview

Low pressure check valves are essential components in various fluid systems, ensuring proper flow direction and preventing backflow. These valves are designed to operate under low pressure conditions, making them ideal for applications in industries such as water treatment, HVAC systems, and oil and gas. In this article, we'll explore the functionality, types, applications, and importance of low pressure check valves.

What is a Low Pressure Check Valve?

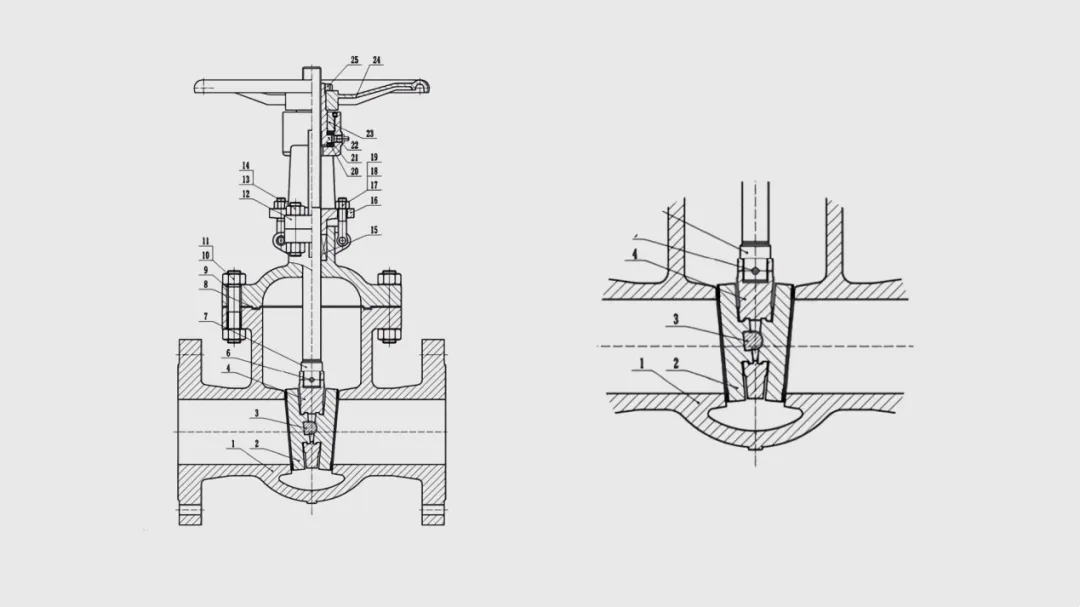

A low pressure check valve is a device used to allow fluid to flow in one direction while preventing it from flowing backward. This simple yet critical mechanism helps maintain system efficiency and safety. The design typically involves a disc or ball that moves in response to the pressure of the fluid. When fluid flows in the desired direction, the valve opens; when there’s a reverse flow, the disc or ball seals the opening, stopping backflow.

Types of Low Pressure Check Valves

Low pressure check valves come in various designs, each suited for specific applications

1. Swing Check Valves These valves use a swinging disc to allow fluid flow. They are commonly used in horizontal piping systems and are known for their ability to handle large volumes of flow.

2. Lift Check Valves These feature a disk that rises and falls with the fluid pressure. They are typically used in vertical pipes and can manage high flow rates.

low pressure check valves

3. Ball Check Valves Utilizing a ball that moves within a chamber, these valves provide a reliable sealing mechanism, making them suitable for systems where backflow prevention is critical.

4. Spring-Loaded Check Valves These valves use a spring mechanism to keep the valve closed until a certain pressure is reached, allowing for precise control over fluid flow.

Applications of Low Pressure Check Valves

Low pressure check valves are used across many sectors. In water treatment plants, they prevent contamination by stopping backflow into clean water supplies. In HVAC systems, these valves ensure that heated or cooled air flows correctly without unwanted reversal. In the oil and gas industry, they protect pipelines and equipment from the damaging effects of backflow, ensuring safe operation.

Importance and Benefits

The importance of low pressure check valves cannot be overstated. They enhance system efficiency, minimize the risk of contamination, and prolong the lifespan of equipment. By preventing backflow, these valves also help maintain a steady pressure within the system, which is crucial for optimal performance. Moreover, they contribute to safety by reducing the likelihood of leaks and bursts caused by pressure imbalances.

Conclusion

Low pressure check valves play a vital role in many fluid handling systems, ensuring efficient and safe operation. Understanding their types and applications can help engineers and technicians make informed decisions about their implementation in various industries. By choosing the right low pressure check valve, one can significantly enhance the reliability and functionality of their fluid systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025