Top Needle Gate Valve Suppliers for Industrial Applications and Reliable Solutions

Understanding Needle Gate Valves and Their Suppliers

Needle gate valves are critical components in various industrial applications, particularly in systems requiring precise flow control. These valves feature a slender, tapered stem that can be adjusted to modulate the flow of fluids, making them ideal for processes that demand fine regulation. As industries evolve and demand for efficient and reliable control mechanisms rises, selecting the right needle gate valve supplier becomes paramount for ensuring operational efficiency and safety.

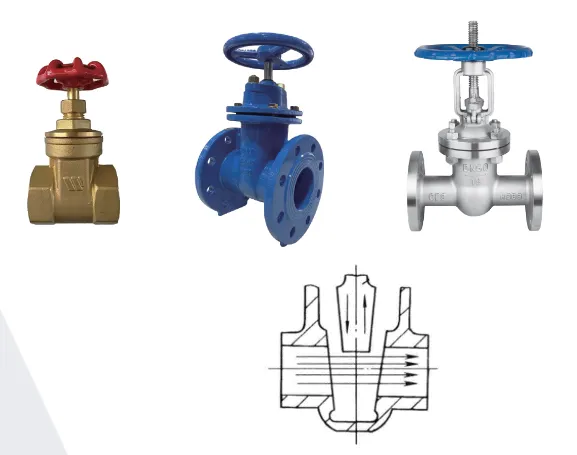

What is a Needle Gate Valve?

The needle gate valve is characterized by its unique design consisting of a long, narrow, conical plug that moves into and out of a matching seat. This design enables it to regulate flow in a highly controlled manner. Unlike traditional gate valves, which are better suited for fully open or fully closed positions, needle gate valves provide greater precision, making them suitable for applications where flow rates need to be finely adjusted.

These valves are commonly used in industries such as oil and gas, water treatment, chemical processing, and pharmaceuticals, where monitoring and controlling the flow of fluids is essential. They can handle a variety of fluids, including gases, liquids, and slurries, and are effective in high-pressure applications.

The Importance of Choosing the Right Supplier

Selecting a reputable needle gate valve supplier is crucial for numerous reasons

1. Quality Assurance The most important characteristic of a reliable supplier is the quality of its products. Reputable suppliers adhere to strict manufacturing standards and guidelines, ensuring that their valves are durable, reliable, and fit for purpose. Valves that fail can lead to costly downtime and safety hazards, making the choice of supplier a critical decision.

needle gate valve supplier

2. Technical Expertise A good supplier not only provides products but also offers technical assistance and expertise. They should have a deep understanding of valve specifications, operational workflows, and compliance requirements. This knowledge enables them to offer tailored solutions that meet the specific needs of their customers.

3. Customization Options Different applications may require customized needle gate valves. A capable supplier should be able to provide options for various materials, sizes, and pressure ratings, ensuring that the valves can withstand the operational demands of your specific processes.

4. Timely Delivery In fast-paced industries, time is of the essence. A reliable supplier will have efficient production capabilities and inventory management systems in place to ensure timely delivery of products. This speed can be a significant factor in maintaining production schedules and meeting project deadlines.

5. After-Sales Support The relationship with a supplier doesn't end with the purchase. A reputable needle gate valve supplier should provide ongoing support, including maintenance services, replacement parts, and troubleshooting assistance. This ensures that customers can rely on their valves for years to come.

Conclusion

Selecting the right needle gate valve supplier is a vital decision for industries dependent on precise fluid control. The right supplier will provide high-quality products, technical expertise, and excellent after-sales support, thereby optimizing operational efficiency and enhancing safety.

When considering a needle gate valve supplier, it is essential to assess their reputation in the industry, evaluate their product offerings, and ensure they align with your specific needs. By doing so, you can secure a reliable source of needle gate valves that not only meet your operational requirements but also contribute to the long-term success of your projects. The importance of this choice cannot be overstated, as it has the potential to significantly impact both operational performance and safety outcomes in your operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025