Stainless Steel Needle Valve for Precise Flow Control in Various Applications

Understanding Needle Valves The Stainless Steel Advantage

In the realm of fluid control, needle valves play a critical role due to their ability to precisely regulate the flow of liquids and gases. Among various materials used for these valves, stainless steel stands out as a preferred option, offering a combination of durability, corrosion resistance, and versatility. This article will explore the significance of needle valves, the advantages of using stainless steel, and their applications in different industries.

What is a Needle Valve?

A needle valve is a type of valve with a slender, tapered point at the end of a valve stem. This design allows for fine control over the flow rate of fluids. Unlike other types of valves that may open or close quickly, needle valves enable precise adjustments, making them ideal for applications where maintaining a specific flow rate is crucial. These valves are commonly used in hydraulic systems, gas lines, and various other scenarios where fluid control is paramount.

Advantages of Stainless Steel Needle Valves

1. Corrosion Resistance One of the most significant advantages of stainless steel needle valves is their inherent resistance to corrosion. Stainless steel, particularly grades like 304 and 316, withstand the effects of moisture, chemicals, and harsh environments. This property makes them ideal for applications in chemical processing, oil and gas, and water treatment industries, where exposure to corrosive substances is common.

2. Durability Stainless steel is known for its strength and toughness. Needle valves made from stainless steel can endure high-pressure conditions and are less likely to fail or experience leaks over time. Their robustness ensures longevity, reducing the need for frequent replacements and maintenance.

3. Temperature Resilience Stainless steel is capable of withstanding elevated temperatures, making stainless steel needle valves suitable for high-temperature applications. This characteristic is particularly important in industries such as power generation and petrochemicals, where fluids may be under extreme thermal stress.

4. Hygienic Properties In industries such as food and beverage, pharmaceuticals, and healthcare, hygienic standards are paramount. Stainless steel’s non-porous surface prevents bacteria and contaminants from adhering, making it a suitable choice for applications requiring high sanitation standards.

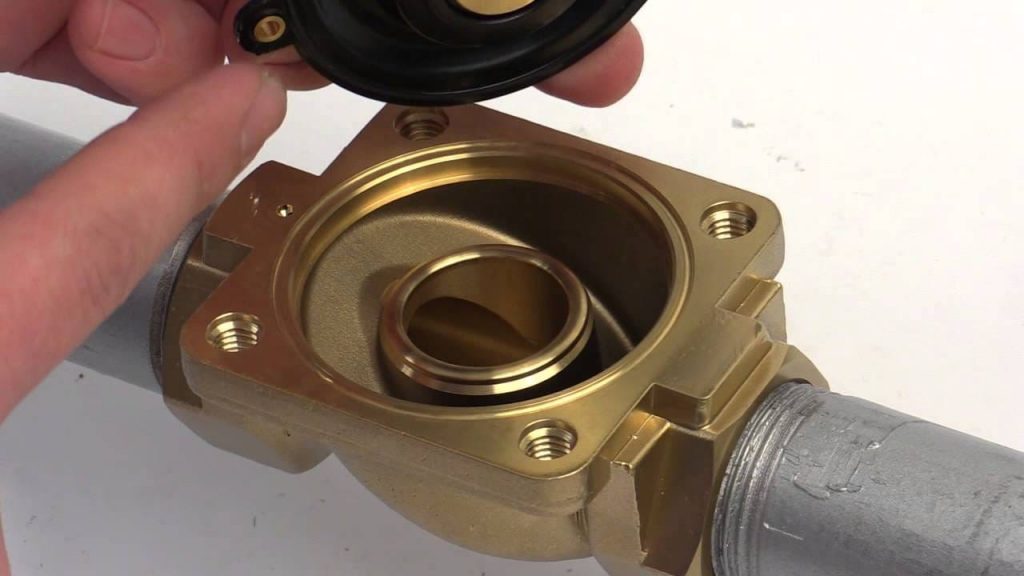

needle valve stainless steel

5. Versatility Stainless steel needle valves are appropriate for a variety of applications, from managing hydraulic oil systems to controlling gas flow in laboratory settings. Their versatility and reliability make them a staple component in many industrial processes.

Applications of Stainless Steel Needle Valves

- Oil and Gas Industry Needle valves are extensively used to manage flow rates of crude oil, natural gas, and refined products. Their precision helps in monitoring and controlling the processes involved in extraction, refining, and transportation.

- Chemical Manufacturing The chemical industry often requires precise flow control of reactive and corrosive fluids. Stainless steel needle valves provide the necessary durability and corrosion resistance to handle these substances safely.

- Water Treatment In water treatment plants, needle valves help control the flow of water and chemicals used in purification processes. Their reliability is critical in maintaining efficient operations.

- Medical Equipment In healthcare, needle valves regulate the flow of gases and liquids in medical devices and systems, ensuring patient safety and accurate dosing of medications.

Conclusion

Stainless steel needle valves represent a blend of functionality and durability, making them an essential component in various industries. Their ability to provide precise flow control, coupled with corrosion resistance and temperature resilience, ensures that they meet the high standards required in critical applications. As industries continue to evolve, the demand for reliable and efficient fluid control solutions will ensure the continued relevance of stainless steel needle valves in future technological advancements.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025