Leading Manufacturer of Advanced Piloted Check Valves for Optimal Flow Control Solutions

Understanding Piloted Check Valves A Comprehensive Overview for Manufacturers

In the world of fluid control systems, various components play pivotal roles in ensuring efficiency and safety. Among these components, the piloted check valve stands out due to its unique functionality and adaptability. This article aims to elucidate the significance of piloted check valves, the manufacturing processes involved, and the advantages they provide in various applications.

What is a Piloted Check Valve?

A piloted check valve is a type of valve that allows fluid to flow in one direction while preventing backflow. Its distinguishing feature is the pilot mechanism that assists in holding the valve closed until a specific pressure differential is reached. This feature makes it especially useful in systems where controlling the backflow is critical, and it can enhance the efficiency of hydraulic systems by reducing energy consumption.

Applications of Piloted Check Valves

Piloted check valves find their applications in myriad sectors ranging from industrial machinery to automotive systems. Common uses include

1. Hydraulic Systems In hydraulic circuits, piloted check valves are widely utilized to ensure that pressure is maintained in a particular chamber while allowing fluid to return to the pump during certain operations.

2. Water Treatment These valves are essential in preventing backflow in water treatment facilities, ensuring that contaminants do not enter clean water sources.

3. Oil and Gas Industry In the oil and gas sector, piloted check valves are employed to maintain safe pressure levels and prevent spills in pipelines.

4. Marine Applications In shipbuilding and marine operations, these valves help prevent flooding by automatically sealing off when backflow is detected.

The Manufacturing Process

The manufacturing of piloted check valves involves several critical steps to ensure precision and reliability. Here’s an overview of the process

1. Design and Prototyping Engineers begin with the design phase, where they create CAD models and prototypes. This stage is crucial for understanding the valve’s operating conditions and flow characteristics.

2. Material Selection Choosing the appropriate materials is essential. Manufacturers often use durable materials like stainless steel, aluminum, and specific polymers depending on the operating environment and fluid type.

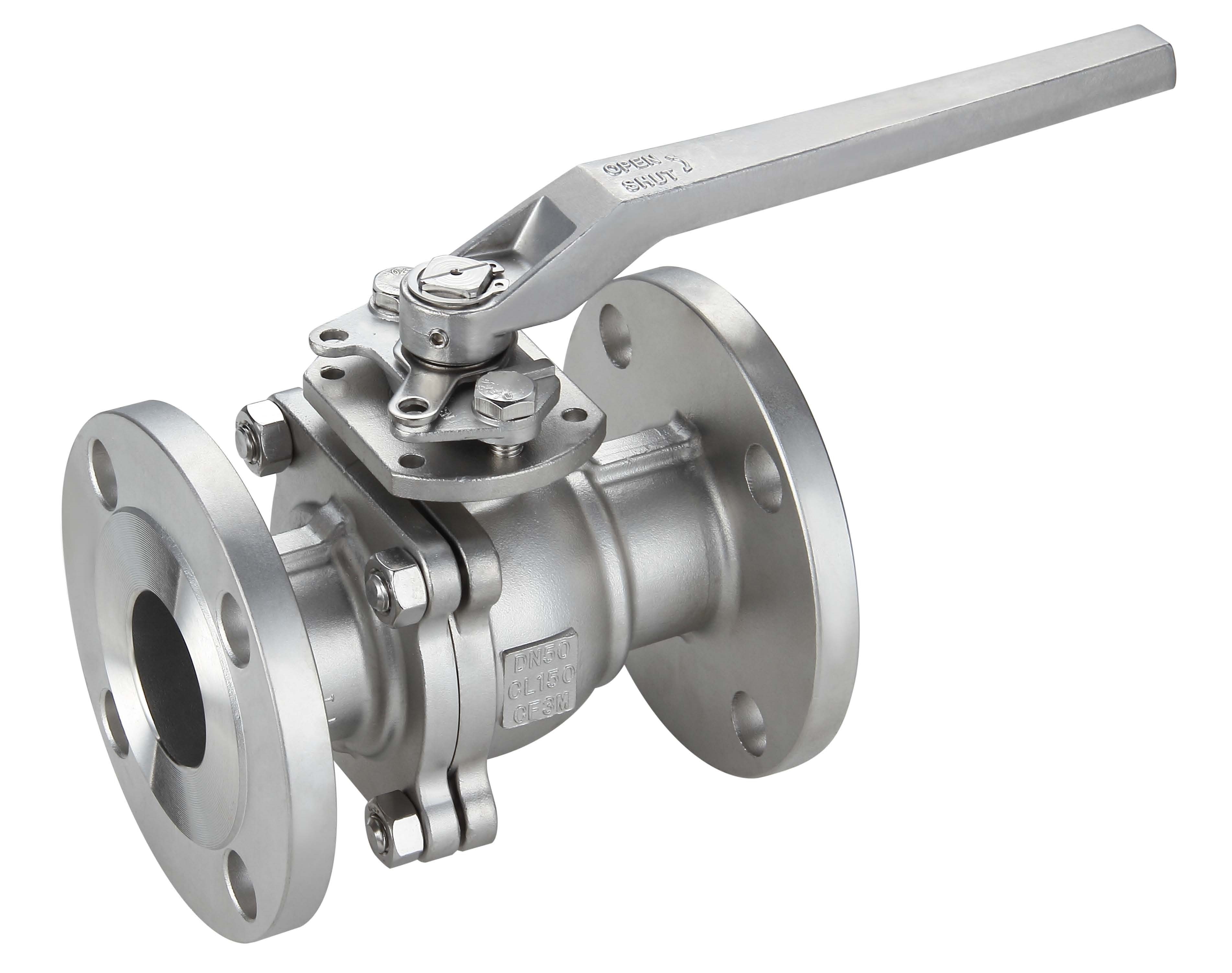

piloted check valve manufacturer

3. Machining The selected materials are then machined into specific shapes using CNC (Computer Numerical Control) machines to ensure high precision.

4. Assembly Once the components are fabricated, they are assembled. This step requires skilled technicians who ensure that every piece fits together correctly and adheres to the strict specifications.

5. Testing Rigorous testing is conducted, including checking for leaks, pressure testing, and ensuring the valve responds correctly under various conditions. Quality assurance is critical at this stage to guarantee durability and functionality.

6. Finishing After passing tests, the valves undergo finishing processes that include surface treatments to protect against corrosion and improve aesthetics.

7. Packaging and Shipping Finally, the finished products are carefully packaged to prevent damage during transportation and shipped to customers.

Advantages of Piloted Check Valves

The advantages of piloted check valves make them a preferred choice for manufacturers and engineers alike

1. Enhanced Control The pilot mechanism provides greater control over fluid flow, allowing for adjustments based on the system’s requirements.

2. Energy Efficiency By minimizing backflow, these valves contribute to more efficient system operation, thereby reducing energy consumption and costs.

3. Improved Safety With their ability to prevent backflow, piloted check valves contribute to safer operational environments, especially in critical applications like oil and gas.

4. Versatility The design of piloted check valves allows them to be used in a broad range of applications, making them adaptable to various industrial needs.

Conclusion

Piloted check valves are an essential component in many hydraulic and fluid systems. Their unique design and functionality make them invaluable in preventing backflow and enhancing system efficiency. For manufacturers, understanding the intricacies of designing and producing these valves is crucial to meeting the demands of diverse industries. As technology progresses, the design and manufacturing processes will continue to evolve, ensuring that piloted check valves remain at the forefront of fluid control solutions.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025