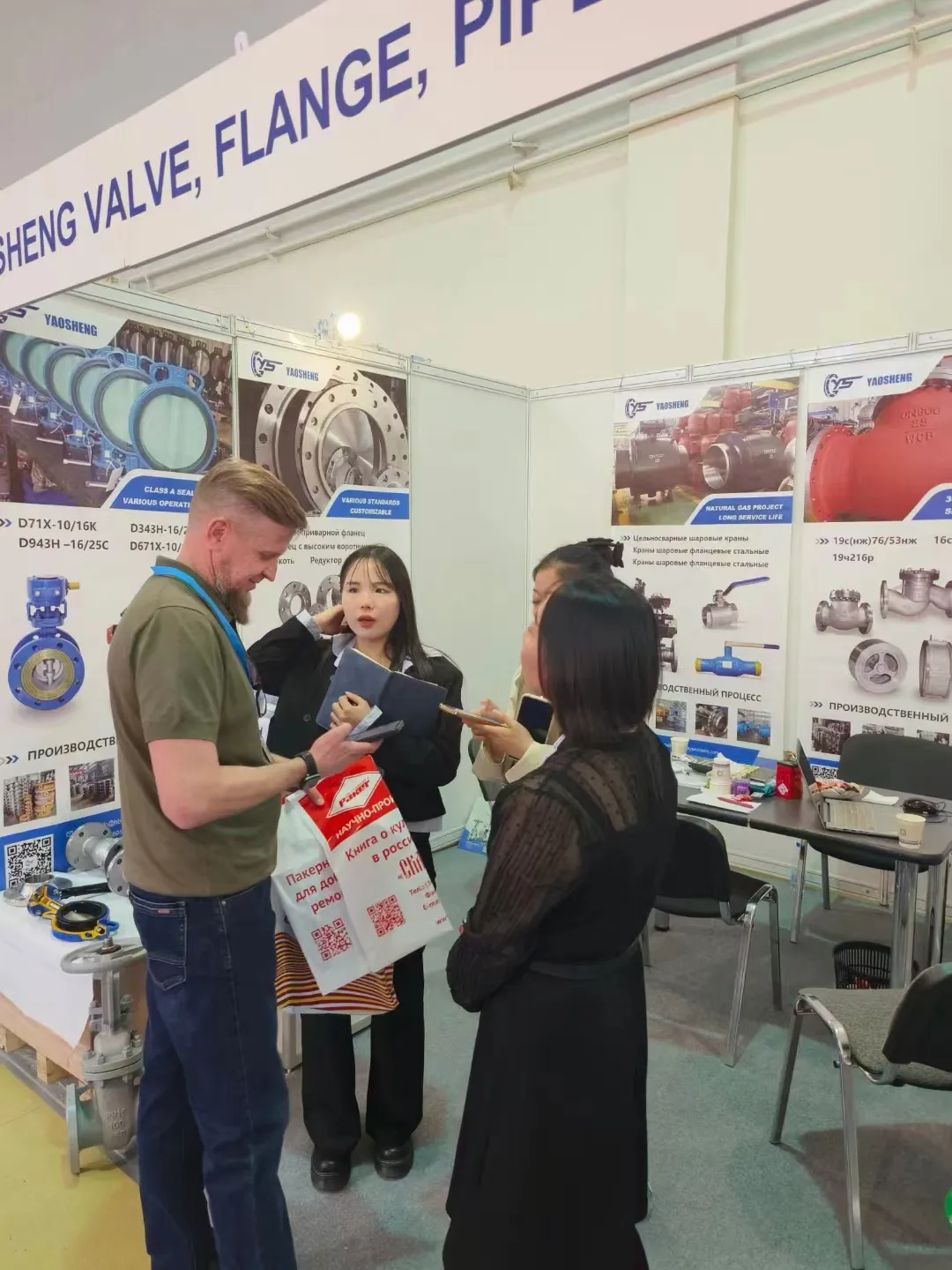

pipe welding fitting suppliers

Understanding Pipe Welding Fitting Suppliers A Comprehensive Overview

In the realm of industrial construction and manufacturing, pipe welding fittings play a crucial role in ensuring that various systems function seamlessly. These fittings, which are designed to connect pipes and facilitate fluid movement in a variety of applications, are essential components in industries such as oil and gas, water treatment, chemical processing, and many others. Given their importance, selecting the right pipe welding fitting suppliers becomes a vital step for businesses looking to ensure quality assurance, compliance with standards, and overall project success.

What Are Pipe Welding Fittings?

Pipe welding fittings are crucial components that allow different sections of piping systems to be joined together. These fittings can be made from a variety of materials including steel, copper, plastic, and more, and they come in various shapes, sizes, and designs. Common types of welding fittings include elbows, tees, reducers, and caps, each serving specific purposes in a piping system. For example, an elbow fitting is used to change the direction of the pipe, while a reducer is used to connect pipes of different diameters.

Importance of Quality Suppliers

Choosing the right supplier for pipe welding fittings is necessary for several reasons. First and foremost, the quality of fittings can significantly impact the integrity and safety of the entire piping system. Poor-quality fittings can lead to leaks, system failures, and potentially hazardous situations. This highlights the importance of sourcing materials from reputable suppliers who adhere to industry standards and regulations.

Moreover, experienced suppliers often provide fittings that meet specific codes such as ASME (American Society of Mechanical Engineers) and ASTM (American Society for Testing and Materials) guidelines. These standards help ensure that the materials used can withstand the pressures and conditions they will face in their intended application.

Factors to Consider When Choosing a Supplier

pipe welding fitting suppliers

1. Experience and Reputation Look for suppliers with a solid track record in the industry. Companies with years of experience are often more reliable, as they have established quality control processes and a better understanding of customer needs.

2. Range of Products A reputable supplier should offer a wide range of pipe welding fittings. This not only includes the fittings themselves but also various sizes, materials, and connection types. Having access to a diverse inventory allows for better alignment with specific project requirements.

3. Certifications and Compliance Confirm that the supplier adheres to necessary certifications and standards. This can include ISO certifications, compliance with local regulations, and meeting international standards for manufacturing processes.

4. Technical Support A good supplier should offer technical assistance and support. This is especially beneficial when selecting the right fittings for unique or complex applications. Having a knowledgeable team to guide you can save time and ensure you make informed decisions.

5. Customer Reviews and References Research customer feedback and seek references to gauge the supplier's reputation. Positive testimonials can be a strong indicator of a supplier’s reliability and product quality.

6. Pricing and Payment Terms While pricing shouldn’t be the only deciding factor, it is essential to consider it alongside quality. Ensure that the supplier can offer competitive pricing while still committing to high-quality products.

Conclusion

The selection of pipe welding fitting suppliers is a critical component of successful project execution in various industries. By considering the factors mentioned above, businesses can find suppliers who not only provide high-quality products but also contribute to the overall efficiency and safety of their operations. As industries continue to evolve, establishing strong partnerships with reliable suppliers will prove paramount in meeting the demands of modern infrastructure. Whether constructing new systems or maintaining existing ones, the role of pipe welding fittings and their suppliers remains indispensable.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025