Jun . 13, 2024 11:00

Back to list

Producer of 12-inch ball valves

Understanding the Significance of a 12-inch Ball Valve Manufacturer

In the realm of industrial piping systems, the role of a high-quality 12-inch ball valve manufacturer cannot be overstated. A 12-inch ball valve is a critical component in managing fluid flow, providing an efficient and reliable means to regulate, start, or stop the passage of substances through pipelines. This article delves into the intricacies of these valves and the manufacturers that specialize in their production.

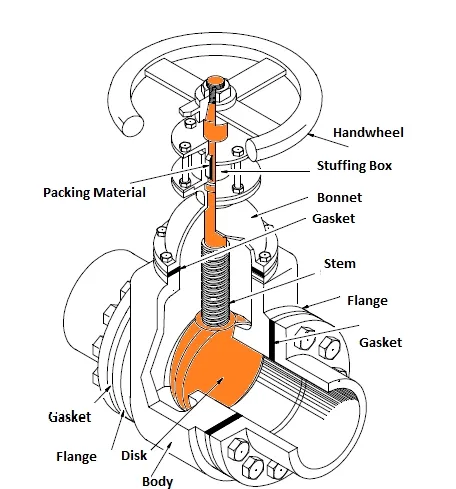

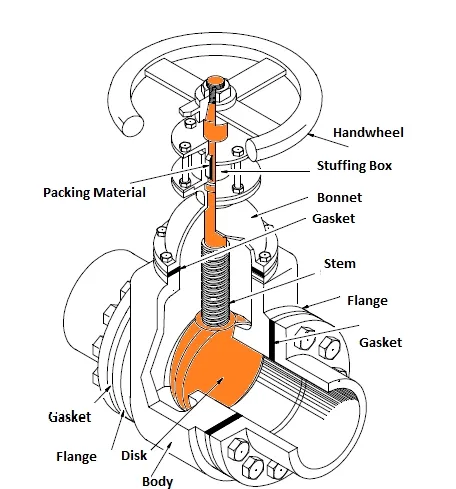

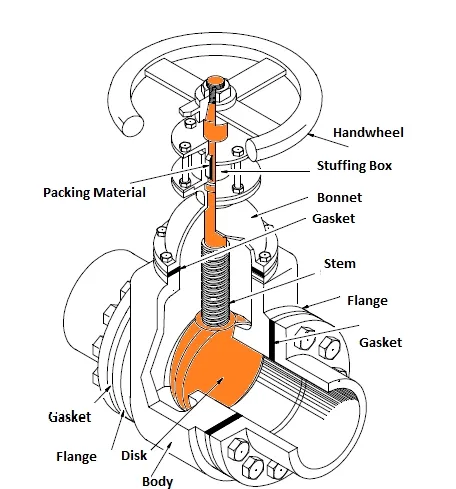

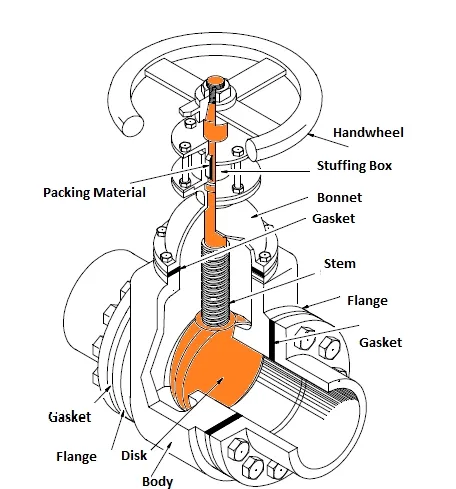

A ball valve, named after its spherical closure element with a bore through its center, operates by rotating the ball a quarter turn to open or close the flow path. In a 12-inch variant, it's designed to handle large-scale operations, typically found in industries such as oil and gas, chemical processing, water treatment, and power generation. The size alone indicates its capacity for handling substantial flow rates and high pressures, making the choice of a manufacturer all the more crucial.

The manufacturing process for a 12-inch ball valve requires precision engineering, robust materials, and stringent quality control measures. Leading manufacturers use materials like stainless steel, carbon steel, or brass, ensuring durability and resistance to corrosion. They also incorporate features like trunnion-mounted balls for added stability, Teflon seats for smoother operation, and anti-blowout stems for enhanced safety.

A reputable 12-inch ball valve manufacturer invests heavily in research and development, constantly refining designs to improve performance and efficiency. They adhere to international standards such as API, ANSI, and ASME, ensuring compliance with industry norms and customer expectations. Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements

Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements 12 inch ball valve manufacturer.

Beyond product excellence, a top-notch manufacturer provides exceptional customer service. This includes customized solutions, prompt delivery, and post-sales support like maintenance and repair services. Their expertise extends to assisting clients in selecting the right valve based on factors like pressure rating, temperature range, and media compatibility.

Furthermore, sustainability is increasingly becoming a focal point for manufacturers. They strive to develop eco-friendly valves, optimizing energy consumption and minimizing environmental impact. This aligns with global efforts towards sustainable industrial practices.

In conclusion, a 12-inch ball valve manufacturer plays a pivotal role in ensuring the smooth functioning and reliability of large-scale industrial processes. Their commitment to quality, innovation, and customer satisfaction is what sets them apart in this competitive landscape. Whether it's for controlling the flow of crude oil in an offshore rig or managing water supply in a municipal network, the right manufacturer can make all the difference in ensuring system integrity and operational efficiency.

12 inch ball valve manufacturer.

Beyond product excellence, a top-notch manufacturer provides exceptional customer service. This includes customized solutions, prompt delivery, and post-sales support like maintenance and repair services. Their expertise extends to assisting clients in selecting the right valve based on factors like pressure rating, temperature range, and media compatibility.

Furthermore, sustainability is increasingly becoming a focal point for manufacturers. They strive to develop eco-friendly valves, optimizing energy consumption and minimizing environmental impact. This aligns with global efforts towards sustainable industrial practices.

In conclusion, a 12-inch ball valve manufacturer plays a pivotal role in ensuring the smooth functioning and reliability of large-scale industrial processes. Their commitment to quality, innovation, and customer satisfaction is what sets them apart in this competitive landscape. Whether it's for controlling the flow of crude oil in an offshore rig or managing water supply in a municipal network, the right manufacturer can make all the difference in ensuring system integrity and operational efficiency.

Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements

Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements Moreover, they offer a range of valve configurations, including full port, reduced port, and V-port, to cater to diverse application requirements 12 inch ball valve manufacturer.

Beyond product excellence, a top-notch manufacturer provides exceptional customer service. This includes customized solutions, prompt delivery, and post-sales support like maintenance and repair services. Their expertise extends to assisting clients in selecting the right valve based on factors like pressure rating, temperature range, and media compatibility.

Furthermore, sustainability is increasingly becoming a focal point for manufacturers. They strive to develop eco-friendly valves, optimizing energy consumption and minimizing environmental impact. This aligns with global efforts towards sustainable industrial practices.

In conclusion, a 12-inch ball valve manufacturer plays a pivotal role in ensuring the smooth functioning and reliability of large-scale industrial processes. Their commitment to quality, innovation, and customer satisfaction is what sets them apart in this competitive landscape. Whether it's for controlling the flow of crude oil in an offshore rig or managing water supply in a municipal network, the right manufacturer can make all the difference in ensuring system integrity and operational efficiency.

12 inch ball valve manufacturer.

Beyond product excellence, a top-notch manufacturer provides exceptional customer service. This includes customized solutions, prompt delivery, and post-sales support like maintenance and repair services. Their expertise extends to assisting clients in selecting the right valve based on factors like pressure rating, temperature range, and media compatibility.

Furthermore, sustainability is increasingly becoming a focal point for manufacturers. They strive to develop eco-friendly valves, optimizing energy consumption and minimizing environmental impact. This aligns with global efforts towards sustainable industrial practices.

In conclusion, a 12-inch ball valve manufacturer plays a pivotal role in ensuring the smooth functioning and reliability of large-scale industrial processes. Their commitment to quality, innovation, and customer satisfaction is what sets them apart in this competitive landscape. Whether it's for controlling the flow of crude oil in an offshore rig or managing water supply in a municipal network, the right manufacturer can make all the difference in ensuring system integrity and operational efficiency. Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025