Different Types of Round Flanges for Various Industrial Applications and Uses

Understanding Round Flanges A Comprehensive Overview

When it comes to piping and plumbing systems, the importance of flanges cannot be overstated. Among the various types of flanges, round flanges are particularly vital due to their widespread applications in numerous industrial sectors. This article delves into the details of round flanges, exploring their characteristics, types, applications, and essential considerations for selecting and using them.

What are Round Flanges?

Round flanges are circular pieces of metal that are used to connect two sections of piping or to attach a valve, pump, or other equipment to a pipe. These flanges feature a central hole that allows for the passage of fluid and are typically bolted to another flange that complements their shape and function. They provide a reliable means of joining different components of a piping system while allowing for ease of assembly and disassembly.

The design of round flanges accommodates various types of connections, including bolted joints, welded joints, and threaded connections, making them versatile for a range of applications. Moreover, they come in different sizes, pressure ratings, and materials, thus catering to diverse operational requirements.

Types of Round Flanges

Round flanges come in several variations, each tailored to specific applications. Some common types include

1. Weld Neck Flanges These flanges have a long tapered neck that can be welded to a pipe. They offer strength and durability, making them suitable for high-pressure applications.

2. Slip-On Flanges Designed to easily slip over the end of a pipe, these flanges are then welded in place. They are ideal for low-pressure applications and are simpler and more cost-effective than weld neck flanges.

3. Blind Flanges Used to seal off the end of a piping system, blind flanges do not have a central hole. They are essential for maintenance and inspection purposes, allowing for the isolation of sections within a system.

4. Socket Weld Flanges These flanges are designed for use with pipes of a matching size, where the pipe is inserted into the flange and welded. This flange type is suitable for high-pressure applications in smaller diameters.

5. Lap Joint Flanges Ideal for systems needing frequent dismantling, lap joint flanges consist of two components—a stub end and a loose flange. They provide flexibility in assembly and disassembly but require precise alignment.

Applications of Round Flanges

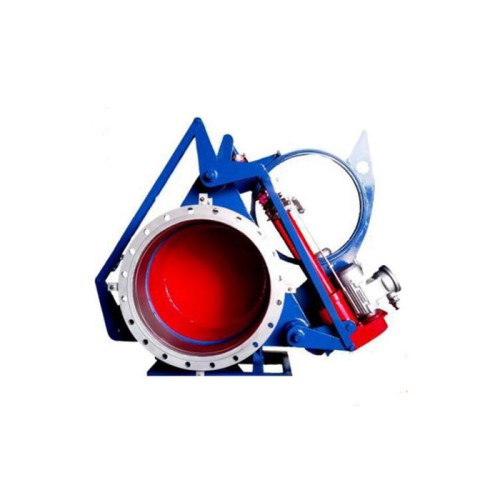

round flanges

Round flanges are utilized across a myriad of industries, bolstering their significance in modern engineering. Common applications include

- Oil and Gas Sector Here, flanges are critical for maintaining the integrity of piping systems that transport crude oil, natural gas, and refined products. Their ability to handle high pressures and temperatures is essential for safety and efficiency.

- Water Treatment Facilities Round flanges facilitate connections between pipes, valves, and other equipment in water treatment plants, ensuring the smooth operation and maintenance of the system.

- Chemical Processing In chemical plants, flanges are used to connect pipes that carry hazardous materials. Their robust design mitigates the risk of leaks and spills.

- HVAC Systems Flanges play a crucial role in heating, ventilation, and air conditioning systems, ensuring secure connections between ductwork and fans or filters.

Choosing the Right Round Flange

When selecting a round flange, several factors should be considered to ensure optimal performance

1. Material Depending on the application, flanges can be made from various materials, including stainless steel, carbon steel, and plastic. The choice of material impacts corrosion resistance, strength, and longevity.

2. Pressure Rating It is essential to select flanges that can handle the pressure of the system. Flanges are rated according to the American National Standards Institute (ANSI) system, ranging from 150 to 2500 psi and beyond.

3. Size The size of the flange must match the pipe size to ensure a secure and effective connection.

4. Standards and Codes Compliance with relevant industry standards (like ASME, ASTM, or API) is crucial for ensuring safety and performance.

Conclusion

Round flanges are integral components in various systems, providing crucial junctions that enable the efficient flow of fluids. Understanding their types, applications, and selection criteria is fundamental for engineers and technicians involved in the design and maintenance of pipeline infrastructures. With their versatility and reliability, round flanges continue to be pivotal in ensuring operational efficiency across multiple industries.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025