socket weld needle valve suppliers

Socket Weld Needle Valve Suppliers A Comprehensive Guide

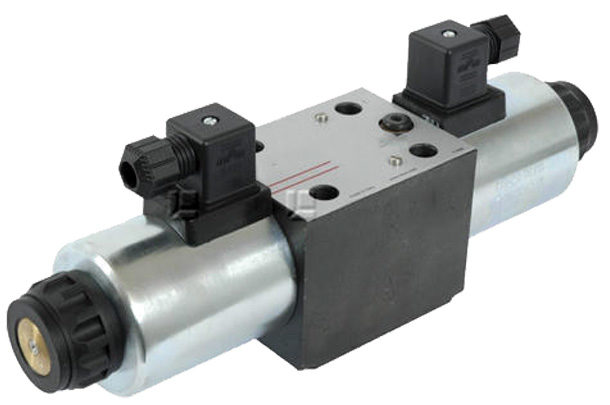

Socket weld needle valves play a crucial role in controlling the flow of fluids in various applications, particularly in high-pressure environments. These valves are designed to provide precise regulation, making them ideal for processes in industries such as oil and gas, chemical processing, and power generation. As the demand for reliable and efficient flow control solutions continues to rise, the importance of sourcing quality socket weld needle valves from reputable suppliers cannot be overstated.

What are Socket Weld Needle Valves?

Socket weld needle valves are specialized valve types designed for high-pressure and high-temperature applications. Unlike traditional threaded valves, socket weld valves connect by inserting a pipe into a valve socket and applying heat to create a solid bond. This method provides a more robust connection, reducing the risk of leakage and ensuring better structural integrity.

The needle aspect refers to the valve's design, which features a long, tapered point and a 360-degree rotation for adjusting the flow rate. This configuration allows fine control of the fluid flow, making needle valves ideal for precise applications where accuracy is essential.

Importance of Choosing the Right Supplier

Selecting the right supplier for socket weld needle valves is essential for ensuring optimal performance and longevity. A reliable supplier should offer products that meet industry standards and comply with necessary regulations, such as ANSI, ASME, and API. Furthermore, they should provide valves made from high-quality materials, including stainless steel, brass, and other corrosion-resistant alloys, ensuring that they can withstand harsh operating conditions.

When evaluating potential suppliers, consider their experience in the industry, customer reviews, and their ability to provide technical support and after-sales service. A knowledgeable supplier can offer valuable insights into which valve configuration best suits your specific application.

socket weld needle valve suppliers

Factors to Consider When Sourcing Needle Valves

1. Material Quality The materials used in the fabrication of socket weld needle valves significantly impact their performance and durability. Suppliers should provide certifications for the materials used to ensure they meet the required industry standards.

2. Size and Specification Needle valves come in various sizes and specifications, tailored to different applications. It’s important to choose a supplier that can provide a range of options to accommodate specific system requirements.

3. Customization In some cases, standard valve designs may not meet the unique needs of an application. Look for suppliers that offer customization options, allowing you to tailor the valves to your specific requirements.

4. Lead Times and Availability Timely delivery can be critical, particularly in industries where downtime can lead to significant productivity losses. Ensure your supplier can meet your lead time requirements to keep your operations running smoothly.

5. Cost While pricing is an important factor, it should not be the sole criterion for selection. Balancing cost with quality and service is essential for a sustainable sourcing strategy.

Conclusion

In conclusion, socket weld needle valves are integral components in fluid control systems across various industries. Finding a reputable supplier is vital for obtaining high-quality valves that meet your application’s specific needs. By considering factors such as material quality, customization options, and supplier reliability, you can ensure that your operations run efficiently and effectively. As you embark on your search for socket weld needle valve suppliers, remember that investing time in selecting the right partner will pay off in the long run, ensuring safety and reliability in your fluid management processes.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025