ss flange ball valve

The Significance of SS Flange Ball Valves in Modern Applications

In the realm of fluid control, valves play a crucial role in ensuring efficiency, safety, and reliability in various systems. Among the various types of valves available, the SS (stainless steel) flange ball valve stands out as a preferred choice due to its robust design and excellent performance characteristics. This article delves into the features, advantages, and applications of SS flange ball valves, highlighting their significance in modern industry.

Understanding SS Flange Ball Valves

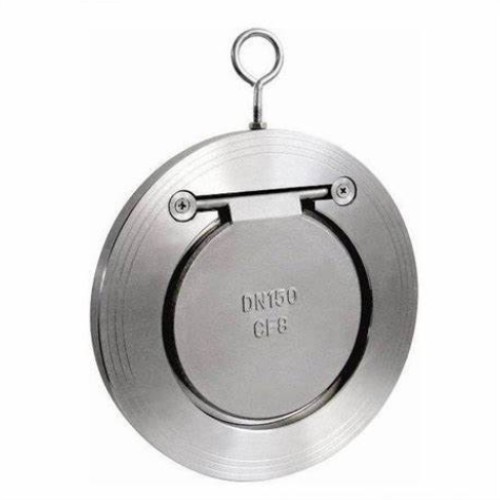

An SS flange ball valve is a type of quarter-turn valve that utilizes a spherical disc, known as a ball, to control fluid flow. The valve is designed with flanged ends, allowing it to be easily mounted between two flanges in a piping system. Made from high-quality stainless steel, these valves offer enhanced resistance to corrosion, high temperatures, and extreme pressures, making them suitable for a wide range of applications.

Key Features

1. Corrosion Resistance Stainless steel is known for its excellent corrosion resistance, making SS flange ball valves ideal for use in harsh environments, including those with corrosive fluids. 2. Durability The robust construction of stainless steel ensures a long service life, reducing the need for frequent replacements and maintenance.

3. Ease of Maintenance SS flange ball valves require minimal maintenance due to their simple design, which facilitates easy access for inspection and repairs.

4. Leak-Free Operation The design of the valve includes a tight seal when in the closed position, ensuring minimal leakage even under high pressure.

5. Versatile Sizes Available in various sizes and pressure ratings, these valves can be tailored to fit specific requirements of different systems.

Advantages of Using SS Flange Ball Valves

1. Efficiency The spherical design of the ball facilitates swift and efficient flow control, allowing for quick opening and closing operations. This characteristic is crucial in applications where time is of the essence.

ss flange ball valve

3. High Flow Capacity SS flange ball valves have a larger flow capacity compared to many other valve types, making them suitable for high-demand applications.

4. Wide Temperature Range These valves can operate effectively across a broad range of temperatures, making them versatile for use in various industrial processes.

Applications in Various Industries

SS flange ball valves are widely used across numerous sectors due to their unique advantages

1. Oil and Gas In the oil and gas industry, these valves are crucial for controlling the flow of crude oil, natural gas, and other fluids, where integrity and reliability are paramount.

2. Chemical Processing Chemical plants often use SS flange ball valves for controlling corrosive substances, ensuring safe and efficient operations.

3. Water Treatment In water and wastewater treatment facilities, these valves help regulate flow and manage the distribution of water resources.

4. Food and Beverage The food industry relies on SS valve types due to their sanitary properties and resistance to corrosion, ensuring the safety and quality of consumables.

5. Pharmaceuticals In pharmaceutical manufacturing, the use of SS flange ball valves aids in maintaining strict hygiene standards and controlling critical processes.

Conclusion

SS flange ball valves are indispensable components in modern fluid management systems, offering unmatched durability, efficiency, and safety. Their versatility across different industries underscores their significance in enhancing operational performance. As industries continue to evolve, the reliance on high-quality valve solutions, such as the SS flange ball valve, is likely to increase, solidifying their position as a foundational element in maintaining the integrity of fluid systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025