Flanged Stainless Steel Y Strainer for Efficient Fluid Filtration Solutions

Understanding Stainless Steel Y Strainer Flanged A Key Component for Efficient Fluid Management

In various industries where fluid management is critical, the choice of components can significantly impact the efficiency and integrity of systems. One such vital component is the stainless steel Y strainer flanged. This device serves as a protective barrier, preventing debris and unwanted particles from interfering with the flow of liquids or gases within pipelines.

What is a Y Strainer?

A Y strainer, named for its distinctive shape that resembles the letter “Y,” is an essential tool for filtering out contaminants in fluid systems. It features a mesh screen that captures particulates while allowing the continuous flow of media. This functionality is crucial in maintaining the operational efficiency of pumps, valves, and other sensitive equipment downstream.

The Importance of Stainless Steel

Stainless steel is the preferred material for Y strainers due to its impressive durability and resistance to corrosion. In industries such as oil and gas, chemical processing, and food and beverage, pipes and components are often exposed to harsh environments. Stainless steel not only withstands high pressures and temperatures but also resists rust and oxidation, ensuring longevity and reliability.

The properties of stainless steel are particularly advantageous in environments that are prone to contamination and where hygiene is paramount. This makes stainless steel Y strainers ideal for water treatment plants, pharmaceutical production, and food processing facilities, where cleanliness is essential.

Flanged Connections

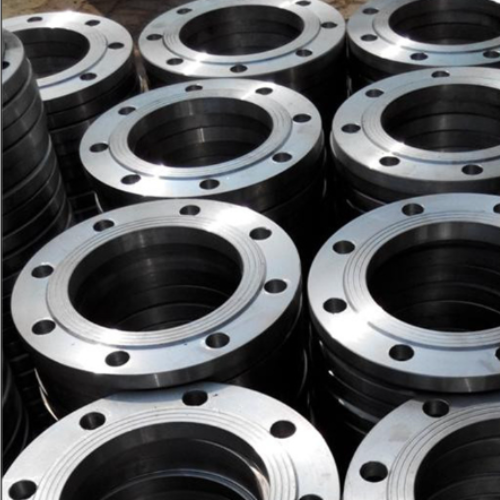

stainless steel y strainer flanged

The ‘flanged’ aspect of the strainer refers to how it connects to piping systems. Flanged connections are widely recognized in industrial applications for their robustness and ease of installation. Each side of the Y strainer has a flat surface with holes that align with corresponding pipe flanges. Bolts are then used to secure the flanged connection, allowing for a tight seal that prevents leaks.

This design not only simplifies maintenance and replacement—since it allows for easy disassembly—but also ensures that the strainer can be integrated into existing systems without extensive modifications. Additionally, the flanged connections can accommodate various piping sizes, making these strainers versatile and adaptable to different applications.

Applications

Stainless steel Y strainers flanged have a broad range of applications across multiple sectors. In the oil and gas industry, they are used to protect pumps and compressors from harmful debris. In water treatment facilities, they ensure that sediments do not clog filtration systems, maintaining clean water standards.

Furthermore, in the food and beverage industry, these strainers help ensure that impurities do not spoil products, upholding safety and quality regulations. Their ability to endure rigorous cleaning processes while avoiding contamination makes them suitable for hygienic applications.

Conclusion

The stainless steel Y strainer flanged is an indispensable component for efficient fluid management across various industries. Its filter mechanism, combined with the durability of stainless steel and the practicality of flanged connections, provides a reliable solution to prevent particulate contamination. As industries continue to prioritize efficiency and safety, the importance of effective filtration systems like stainless steel Y strainers cannot be overstated. Investing in quality strainers not only enhances system performance but also ensures compliance with industry standards, thereby safeguarding operational integrity.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025