Lever-operated swing check valve for efficient fluid control and prevention of backflow

Understanding Swing Check Valves with Lever A Comprehensive Overview

In fluid mechanics, check valves play a crucial role in various applications by preventing backflow in piping systems. Among the different types of check valves, the swing check valve with a lever is one of the most reliable designs employed in industrial settings. This article delves into the functionality, advantages, and applications of swing check valves with levers, providing insight into their importance in fluid control systems.

What is a Swing Check Valve?

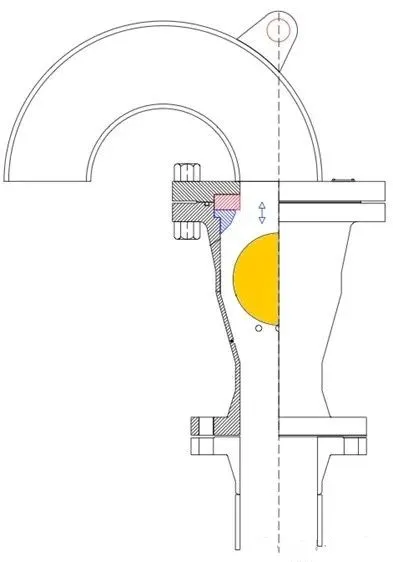

A swing check valve is a type of valve that uses a swinging disc to allow or restrict the flow of fluid. When the fluid flows in the intended direction, the disc swings open, allowing smooth passage. Conversely, when the fluid attempts to flow backward, the disc swings closed, effectively sealing the valve and preventing any backflow. This automatic operation is what distinguishes check valves from other types of valves, which require manual intervention.

The Role of the Lever

Swing check valves can include a lever mechanism to enhance their performance, particularly in larger applications or those with significant pressure differentials. The lever provides a mechanical advantage that assists in the disc's closure, ensuring rapid and secure sealing against backflow.

One of the key benefits of integrating a lever into a swing check valve is its ability to facilitate easier operation and maintenance. The lever allows for manual override capability, giving operators the option to keep the valve open temporarily if necessary. This feature is particularly useful during system maintenance or when conditions require specific flow control.

Advantages of Swing Check Valves with Levers

1. Reliable Backflow Prevention The fundamental advantage of all check valves, including swing check valves with levers, is their ability to prevent backflow. This is vital for protecting pumps, compressors, and other equipment from damage caused by reversing flow.

swing check valve with lever

2. Simple Design and Operation The straightforward mechanics of swing check valves make them easy to operate. With few components involved, the likelihood of malfunctions is reduced, contributing to reliability and longevity in service.

3. Low Pressure Drop Swing check valves typically feature a disc that is designed to offer minimal resistance to flow. This design translates to lower pressure drops across the valve, promoting energy efficiency in the system.

4. Versatility Swing check valves with levers can be used in a variety of applications, from water treatment and oil refining to HVAC systems. Their ability to handle different fluid types, including liquids and gases, further enhances their applicability.

5. Ease of Maintenance The lever mechanism allows for easier access to the valve's internal components during maintenance checks. This design minimizes downtime, ensuring that systems remain operational with minimal interruptions.

Applications of Swing Check Valves with Levers

Swing check valves with levers find extensive use in various sectors. In water distribution systems, they ensure smooth flow and prevent contamination from backflow. In the chemical processing industry, these valves help maintain the integrity of fluid systems by controlling flow direction effectively. Furthermore, in power generation, they safeguard pumps and compressors during operation, enhancing overall system reliability.

Conclusion

Swing check valves with levers are indispensable components in modern fluid control systems. Their unique design and functionality offer businesses a reliable means of ensuring proper flow management and preventing backflow. With advantages such as low maintenance requirements, energy efficiency, and versatile applications, these valves stand out as a smart choice for industries requiring effective fluid control solutions. As technology advances, the design and materials used in these valves will likely evolve, further optimizing their performance and expanding their use in various sectors. Investing in high-quality swing check valves with levers is not just a choice for today; it's a commitment to the reliable performance and longevity of your fluid systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025