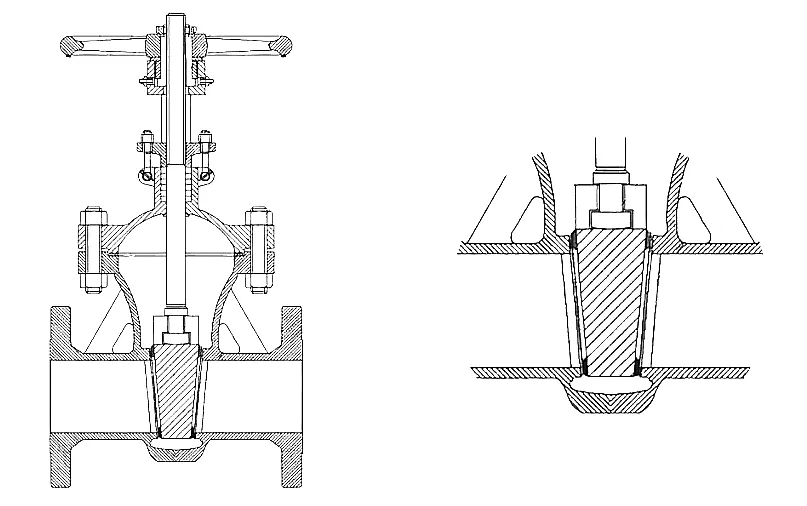

tee flange

Understanding Tee Flanges in Piping Systems

Tee flanges play a crucial role in various piping systems used across industries such as oil and gas, water treatment, and chemical processing. These specialized components are designed to create a robust connection between pipes and fittings, facilitating the smooth flow of fluids while ensuring the integrity and safety of the entire system.

A tee flange is essentially a type of flange that resembles the letter “T.” It is used to connect three sections of piping at a junction, allowing for branching off from a main pipeline. The design typically features a flat surface with bolt holes for easy attachment to other flanges or equipment, ensuring a secure and leak-proof connection.

Material Selection and Types

Tee flanges are available in various materials, including carbon steel, stainless steel, and PVC, among others. The choice of material is crucial, as it must withstand the specific pressures, temperatures, and corrosive conditions of the application. For instance, stainless steel is often preferred in applications involving corrosive substances, while carbon steel is commonly used in less severe environments.

Moreover, tee flanges come in different types, such as threaded, welded, or slip-on. Each type has its advantages depending on the application requirements. For example, welded tee flanges provide a stronger connection suitable for high-pressure systems, whereas threaded flanges offer ease of installation and maintenance in lighter-duty applications.

tee flange

Installation and Maintenance

Proper installation of tee flanges is essential to ensure their effectiveness and longevity in a piping system. The key steps involve aligning the flange faces, inserting bolts through the pre-drilled holes, and tightening them evenly to create a tight seal. It’s important to follow manufacturer specifications and industry best practices during installation, as improper handling can lead to leaks or failures.

Routine maintenance is also critical to prolong the lifespan of tee flanges. This includes regular inspections for signs of wear, corrosion, or leaks. If any issues are detected, timely repairs or replacements can avert more significant problems down the line. Utilizing the correct gasket and following appropriate torque specifications during installation can minimize the risk of future complications.

Applications and Advantages

Tee flanges are widely used in various applications, including water distribution systems, chemical transport, and oil refineries. Their ability to branch off a main pipeline without compromising flow makes them invaluable in complex systems. Additionally, they are often easier to install and maintain compared to other joint types, which can save time and resources.

In summary, tee flanges serve as essential components in many piping systems, enabling efficient fluid transport while ensuring safety and structural integrity. Understanding their types, materials, and proper installation techniques is vital for engineers and technicians working in any industry that relies on piping systems. By choosing the right tee flange for the application and adhering to best practices for installation and maintenance, the overall reliability and performance of the piping system can be significantly enhanced.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025