Top Manufacturers of Internal Thread Globe Valves for Reliable Performance

Internal Thread Globe Valve Manufacturers An Overview

Globe valves are essential components in various industrial applications, providing effective regulation of fluid flow in a piping system. Among the different types of globe valves available in the market, internal thread globe valves are particularly notable for their secure and robust connection that reduces the risk of leaks. This article delves into the key aspects of internal thread globe valve manufacturers, their product offerings, and the considerations that end-users should keep in mind when selecting a suitable manufacturer.

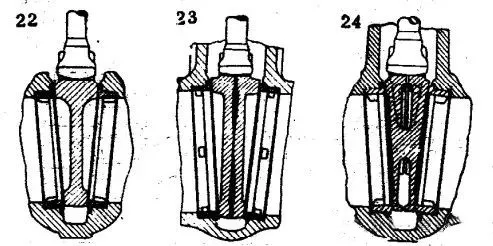

Understanding Internal Thread Globe Valves

Internal thread globe valves feature threaded ends that allow them to be screwed directly into the piping system. This design enhances their ease of installation and maintenance while ensuring a tight seal. They are widely used in various industries, including water treatment, oil and gas, chemical processing, and HVAC systems. The internal threading provides a mechanical connection that is less susceptible to vibration and thermal expansion, making it suitable for high-pressure and high-temperature applications.

Key Features of Internal Thread Globe Valves

1. Design and Construction Internal thread globe valves are typically constructed from durable materials such as stainless steel, carbon steel, or brass, ensuring their longevity and resistance to corrosion. The design usually includes a spherical body shape that minimizes resistance to flow, allowing for efficient regulation of the medium passing through.

2. Flow Control The primary function of a globe valve is to regulate fluid flow. The internal threaded design facilitates a reliable closure mechanism, allowing for precise control over the flow rate. This capability makes them invaluable in applications where maintaining specific pressures and flow rates is critical.

Selecting a Reliable Manufacturer

internal thread globe valve manufacturer

When it comes to choosing an internal thread globe valve manufacturer, several factors warrant consideration

1. Quality and Standards It is crucial to choose manufacturers that adhere to international quality standards, such as ISO 9001. High-quality materials and robust manufacturing processes ensure that the valves can withstand the rigors of their intended applications.

2. Customization Options Depending on specific industry requirements, users may need valves with custom features such as different sizes, pressure ratings, or material compositions. A good manufacturer should offer customization options to meet these diverse needs.

3. Experience and Reputation Manufacturers with extensive experience in the industry are often more reliable as they have a track record of producing high-quality products. Checking customer reviews, case studies, and industry certifications can provide insights into a manufacturer’s reputation.

4. Technical Support and Services A comprehensive customer support system is essential when selecting a manufacturer. This includes not only pre-sale assistance but also after-sale services such as maintenance, repair, and troubleshooting support.

5. Cost Considerations While quality should not be compromised for cost, it's important to compare pricing among different manufacturers. A cost-effective solution that meets all quality and operational requirements can lead to significant savings over time.

Conclusion

Internal thread globe valves play a critical role in fluid control across various industrial applications. By understanding the key features of these valves and the critical factors when selecting a manufacturer, businesses can ensure that they choose a reliable supplier that meets their operational needs. Investing the time to research and select the right internal thread globe valve manufacturer will ultimately lead to improved efficiency and reliability in fluid management processes.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025