types of control valve and applications

Types of Control Valves and Their Applications

Control valves are critical components in various industrial applications, regulating fluid flow, pressure, temperature, and other variables to ensure processes run smoothly and efficiently. Understanding the different types of control valves and their specific applications is vital for engineers and technicians involved in fluid dynamics and process control systems. This article explores the major types of control valves and their applications across various industries.

1. Globe Valves

Globe valves are one of the most versatile types of control valves. Their design features a spherical body and an internal baffle that routes the flow of fluid. This configuration allows for precise flow control, making globe valves ideal for throttling applications. They are widely used in steam, gas, and water systems in chemical plants and power generation facilities due to their ability to manage flow effectively in varying conditions.

2. Ball Valves

Ball valves are characterized by a spherical closure element that rotates within the valve body. They are known for their quick on/off capabilities and excellent sealing properties. While primarily used as shut-off valves, they can also be modified for control applications when precision is not the utmost priority. Ball valves are commonly found in pipelines handling corrosive fluids, gases, and high-pressure conditions due to their robustness and reliability.

Butterfly valves consist of a rotating disc that regulates flow within a pipe. These valves are lightweight, compact, and easy to operate, making them suitable for applications requiring fast opening and closing. They are often employed in water distribution systems, wastewater management, and HVAC systems. While they provide less precise control compared to globe valves, their minimal pressure drop makes them a preferred choice for large-diameter pipes.

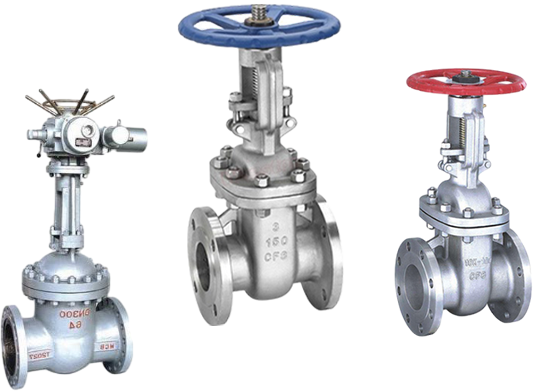

4. Gate Valves

types of control valve and applications

Gate valves are spherically designed for the full flow of fluid and are typically used in applications requiring a straight line flow of fluid with minimum restriction. These valves are either fully open or closed, which makes them unsuitable for throttling. Nonetheless, they are commonly employed in high-pressure and high-temperature applications, such as in oil and gas pipelines or steam lines, where they can facilitate substantial flow without a significant drop in pressure.

5. Check Valves

Check valves are primarily used to ensure that fluid flows in one direction only. They prevent backflow, thus protecting pumps and other equipment from damage. These valves are commonly found in wastewater treatment, hydraulic systems, and various industrial applications where safeguarding against the reversal of flow is crucial.

6. Pressure Relief Valves

Pressure relief valves are vital in maintaining safety and preventing overpressure situations within vessels and systems. These valves automatically release pressure when it exceeds a preset limit, thereby protecting equipment and preventing accidents. They play a critical role in industries such as oil and gas, power generation, and chemical manufacturing, ensuring that operations remain within safe parameters.

7. Electric and Pneumatic Control Valves

Electric and pneumatic control valves are equipped with actuators that allow for automated control based on various parameters such as flow rates, temperature, and pressure. These valves are extensively used in process industries, where precise control and rapid adjustments are necessary to optimize performance and ensure safety. They facilitate remote monitoring and automation, increasing operational efficiency.

Conclusion

The choice of control valve type is contingent upon the specific requirements of an application, including flow control precision, media type, pressure levels, and operational environment. A thorough understanding of the diverse types of control valves and their respective applications equips engineers and system operators to optimize processes and ensure operational safety. With advancements in technology, the functionalities of control valves continue to evolve, making them indispensable in modern industrial applications.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025