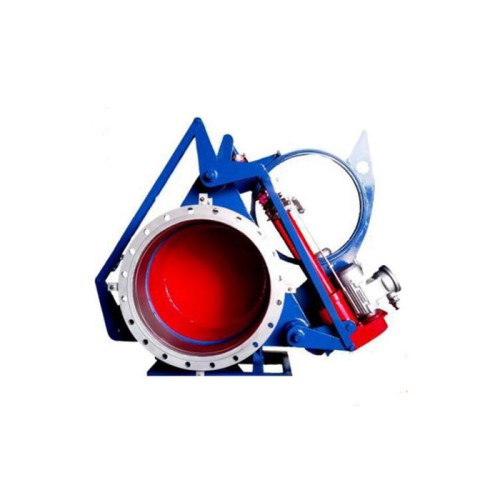

vertical check valves

Understanding Vertical Check Valves Function, Applications, and Benefits

In the realm of fluid dynamics and mechanical engineering, valves play a crucial role in the management of fluid flow. Among these components are vertical check valves, a specific type designed to allow fluid to flow in one direction while preventing backflow. This article delves into the characteristics, applications, and advantages of vertical check valves, offering insights into why they are vital in various industrial settings.

What is a Vertical Check Valve?

A vertical check valve is designed to be installed in a vertical orientation, where the flow of fluid occurs primarily from the bottom to the top. This configuration allows gravity to assist in the operation of the valve. The primary function of a vertical check valve is to prevent reverse flow, which can cause operational inefficiencies and potential damage to equipment and piping systems. Depending on the design, vertical check valves can be constructed with a swing mechanism or a lift mechanism, each suited for different applications and flow conditions.

How Do Vertical Check Valves Work?

Vertical check valves operate on the principle of differential pressure. When fluid flows in the intended direction, the pressure differential opens the valve, allowing fluid to pass through. If there is any attempt for backflow, the valve automatically closes, utilizing gravity or spring mechanisms to create a seal. This mechanism ensures that the pressure needed to reverse the flow is greater than the pressure created by the valve, effectively protecting the system from contamination, water hammer, and other fluid dynamics issues.

Applications of Vertical Check Valves

Vertical check valves are widely used in a variety of industries, including

1. Water Supply Systems They are used in municipal water systems to prevent backflow, protecting the water supply from contaminants and ensuring safe drinking water is delivered to homes and businesses. 2. Wastewater Treatment In wastewater management, vertical check valves help manage the flow of sewage and treated water, preventing backflow that could lead to system failures or pollution.

3. Industrial Processes In manufacturing and chemical processing, vertical check valves are essential for managing the flow of fluids without risking contamination or process disruptions. They are commonly used in pump discharge lines, cooling systems, and in conjunction with other valves.

vertical check valves

4. Heating and Cooling Systems These valves also find their application in HVAC systems to maintain efficiency and prevent backflow in pipework associated with heating and cooling processes.

5. Agricultural Irrigation Vertical check valves assist in water distribution systems, allowing for efficient irrigation without the risk of backflow that could lead to contamination of clean water supplies.

Advantages of Vertical Check Valves

The use of vertical check valves offers several advantages, including

- Space Efficiency The vertical design saves space in installation compared to horizontal configurations, which is particularly beneficial in areas with space constraints.

- Reduced Backflow Risk By preventing reverse flow, these valves help maintain system integrity and protect against contamination, which is crucial in health-sensitive applications.

- Reliable Operation With fewer moving parts and a design that utilizes gravity, vertical check valves tend to offer reliable and consistent performance, reducing maintenance needs.

- Versatile Application Their ability to function effectively in various industries underscores their versatility and the adaptability of their design.

Conclusion

Vertical check valves are an indispensable component in many fluid management systems, ensuring that flow is maintained in one direction while safeguarding processes from backflow issues. With their efficient design and broad applicability across various industries, these valves contribute significantly to the reliability and safety of fluid handling systems. As technology continues to advance, the evolution of vertical check valves will likely enhance their performance and broaden their applications, solidifying their importance in fluid control solutions.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025