wholesale modulating globe valve

Wholesale Modulating Globe Valve An Essential Component for Fluid Control Systems

In today’s industrial landscape, fluid control is a critical aspect across a multitude of applications. From chemical processing to water management, the efficiency and accuracy of fluid handling systems are paramount. Among the various equipment options available in the market, the modulating globe valve stands out due to its ability to regulate flow effectively. This article explores the significance of wholesale modulating globe valves, their advantages, applications, and key considerations for purchasing them in bulk.

Understanding Modulating Globe Valves

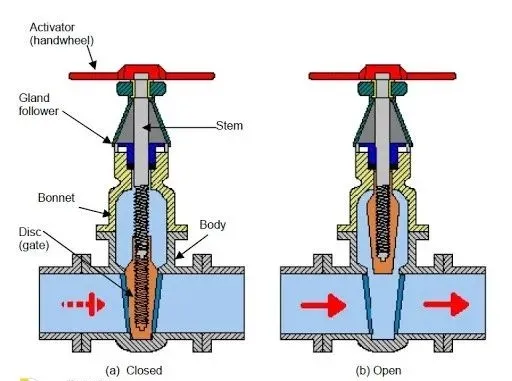

Modulating globe valves are designed to regulate the flow of fluid in a system effectively. Unlike standard valves that are often used for on/off operations, modulating globe valves allow for varying degrees of flow, which can be crucial in applications that require precise flow control. They utilize a movable plug or disc that can be positioned at different heights within the valve body, enabling fine-tuning of fluid passage.

Advantages of Modulating Globe Valves

1. Precision Control One of the primary benefits of modulating globe valves is their ability to provide precise control over water, steam, or fluid flow. This precision is essential in processes where temperature, pressure, or fluid velocity needs to be maintained within strict limits.

2. Durability and Reliability Typically constructed from high-quality materials such as stainless steel, bronze, or carbon steel, modulating globe valves are designed to withstand harsh conditions, making them a reliable choice for industrial applications.

3. Versatile Applications These valves are suitable for a wide range of applications, including HVAC systems, water treatment plants, chemical processing, and power generation. Their versatility increases their value, especially when purchased wholesale.

5. Easy Maintenance With their simple construction, modulating globe valves are generally easy to maintain. This ease of maintenance translates into reduced downtime and lower operational costs.

wholesale modulating globe valve

Wholesale Purchasing Key Considerations

Purchasing modulating globe valves in wholesale can lead to significant cost savings for businesses. However, several factors should be considered

1. Quality Assurance Ensure that the valves meet industry standards and are sourced from reputable manufacturers. Quality control is crucial to prevent failures that could lead to costly downtimes.

2. Specifications Choose valves based on the specific requirements of your application. Factors such as size, material, pressure rating, and type of fluid being handled are critical in selecting the appropriate valve.

3. Supplier Reliability Work with suppliers that have a solid reputation for reliability and timely deliveries. A good supplier will provide comprehensive support and guidance, ensuring you make informed decisions.

4. Bulk Discounts Inquire about bulk discount options when purchasing wholesale. Many suppliers offer reduced prices for larger quantities, ultimately allowing businesses to optimize their budgets.

5. After-Sales Support Consider suppliers that offer excellent after-sales service, including warranty options and technical support, as this can enhance your overall purchasing experience.

Conclusion

Wholesale modulating globe valves play a pivotal role in optimizing fluid control across various industries. Their ability to provide accurate flow regulation and durability makes them indispensable for efficient operations. By considering key factors when purchasing wholesale, businesses can ensure they acquire high-quality valves that meet their specific needs while also enjoying significant cost savings. Investing in reliable modulating globe valves is a strategic decision that can enhance overall operational efficiency and productivity in any fluid handling system.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025