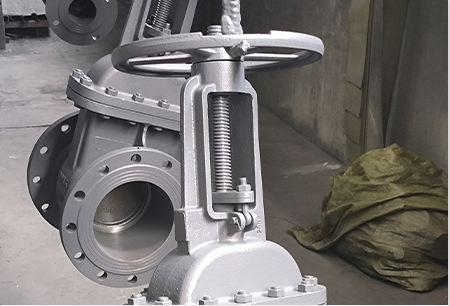

yaosheng 3000 psi ball valve

The Benefits and Applications of 3000 PSI Ball Valves

In the realm of industrial fluid control, ball valves are among the most popular and reliable components. Particularly, the 3000 PSI ball valve has gained significant importance due to its ability to handle high-pressure environments. This article explores the features, advantages, and applications of 3000 PSI ball valves, shedding light on why they are essential in various industries.

Understanding Ball Valves

Ball valves are quarter-turn valves that utilize a spherical obstruction — or ball — to control the flow of fluid through a passageway. The ball is equipped with a hole or port that, when aligned with the flow, allows fluid to pass through. Conversely, when the ball is rotated 90 degrees, the port is perpendicular to the flow, effectively stopping it. This simple yet effective design enables quick and reliable shut-off capabilities, making ball valves ideal for on-off applications.

Features of 3000 PSI Ball Valves

3000 PSI ball valves are specifically designed to withstand high pressure, making them suitable for demanding applications. They are typically constructed from high-strength materials, such as stainless steel or carbon steel, ensuring their ability to endure extreme conditions. Additionally, these valves are often equipped with features like

1. Trunnion Mounted Design In high-pressure applications, trunnion mounted ball valves provide enhanced stability and durability. This design helps to mitigate the risk of valve movement during operation, providing smooth and consistent flow control.

2. Soft and Hard Sealing Options Depending on the application, 3000 PSI ball valves can be fitted with either soft-seated or metal-seated options. Soft-seated valves offer excellent sealing capabilities, suitable for low-pressure, low-temperature applications, while metal-seated options are designed for high-temperature and high-pressure environments, providing longevity and reliability.

3. Corrosion Resistance Many 3000 PSI ball valves are coated or constructed with materials that resist corrosive substances, extending their lifespan and reducing maintenance costs.

Advantages of 3000 PSI Ball Valves

The utilization of 3000 PSI ball valves comes with several advantages

- High Pressure Handling The primary benefit of these valves is their ability to manage high-pressure systems effectively. This characteristic makes them indispensable in oil and gas, petrochemical, and power generation industries.

yaosheng 3000 psi ball valve

- Quick Operation The quarter-turn mechanism allows for rapid opening and closing, which is crucial in emergency situations or processes requiring immediate adjustments.

- Low Torque Requirement Due to their design, ball valves require less torque to operate compared to other valve types, which means they can be easily controlled manually or with automated systems.

- Minimal Pressure Drop The streamlined design of ball valves results in minimal turbulence and a low-pressure drop across the valve, which is essential for maintaining system efficiency

.Applications of 3000 PSI Ball Valves

3000 PSI ball valves find applications across various industries

1. Oil and Gas These valves are essential in upstream and downstream applications, controlling the flow of crude oil and natural gas under high pressure.

2. Chemical Processing In chemical plants, ball valves control corrosive, toxic, or volatile substances, ensuring safe and efficient processing.

3. Water Treatment High-pressure ball valves are used in water and wastewater treatment facilities to regulate flow and pressure in various stages of the treatment process.

4. Power Generation In power plants, particularly those utilizing steam, 3000 PSI ball valves manage steam and water flows, contributing to the efficient operation of boilers and turbines.

5. HVAC Systems These valves are also employed in high-pressure heating, ventilation, and air conditioning systems to control flow and maintain desired pressures.

Conclusion

In conclusion, 3000 PSI ball valves are indispensable components in high-pressure fluid control applications, offering unmatched durability, reliability, and efficiency. Their ability to quickly shut off or regulate flow makes them a preferred choice across various industries, including oil and gas, chemical processing, and power generation. As industrial processes continue to evolve, the demand for robust, high-pressure solutions like 3000 PSI ball valves will undoubtedly grow, highlighting their critical role in modern engineering and technology. Investing in quality ball valves ensures not only the safety and efficiency of operations but also contributes to long-term cost savings through reduced maintenance and failure rates.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025