jun . 30, 2024 12:50

Back to list

Electrically Operated Butterfly Valve Manufacturer Expert Solutions

Electric Actuated Butterfly Valve Manufacturing A Key Industry Perspective

In the realm of industrial automation, the electric actuated butterfly valve factory plays a pivotal role in the seamless functioning of various sectors, from chemical processing to water treatment and oil refineries. These specialized valves, a fusion of engineering precision and technological innovation, have become indispensable components in managing fluid control systems.

An electric actuated butterfly valve, as the name suggests, is a valve that uses an electric motor to operate the butterfly disc within the valve. The 'butterfly' is a disc positioned in the center of the pipe, which rotates to regulate flow when the valve is actuated. The integration of electric actuators adds a level of convenience and precision to this mechanism, allowing for remote operation, automated flow control, and enhanced efficiency.

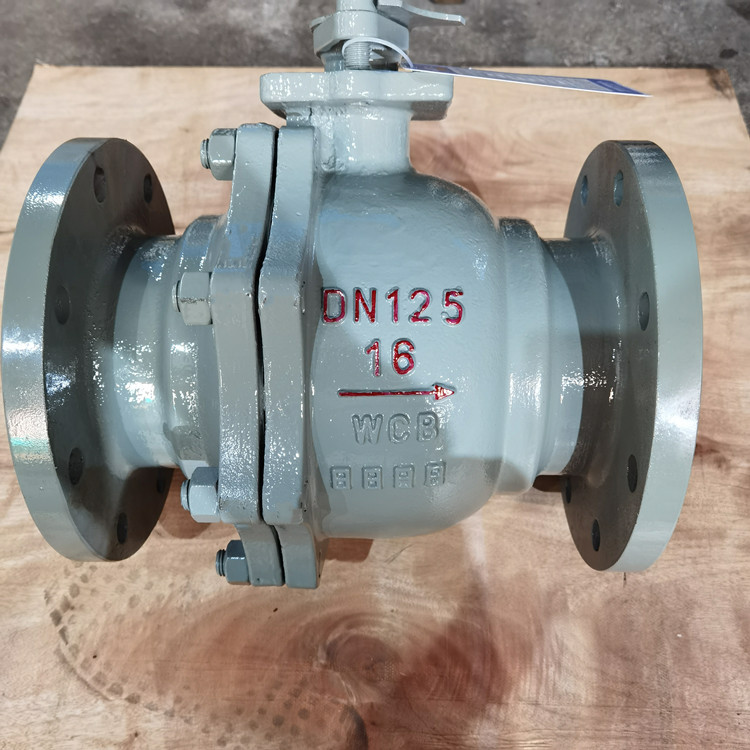

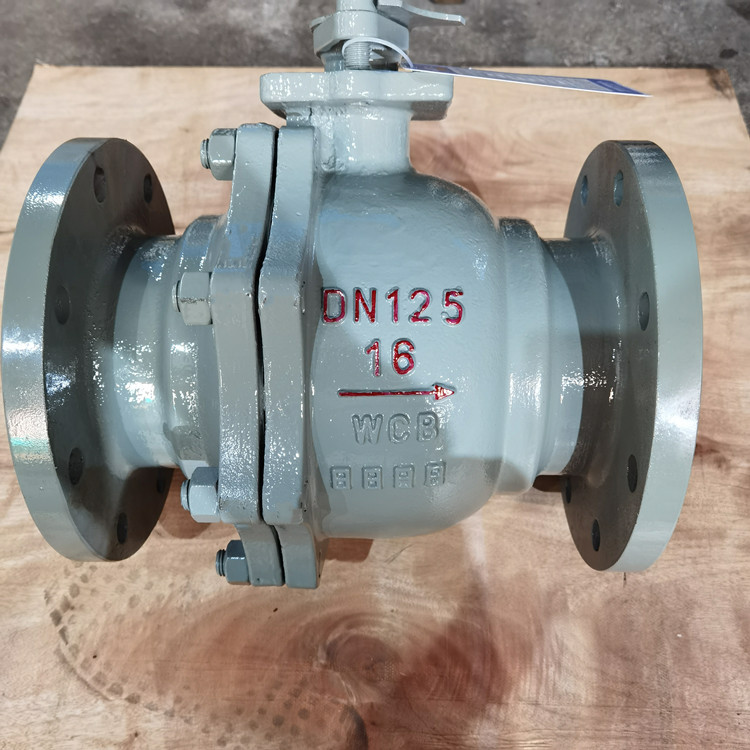

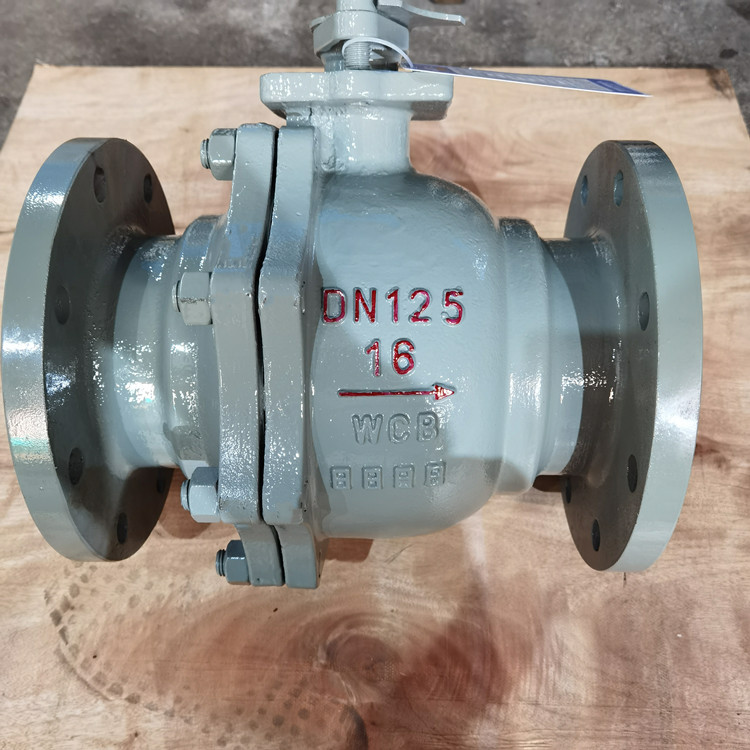

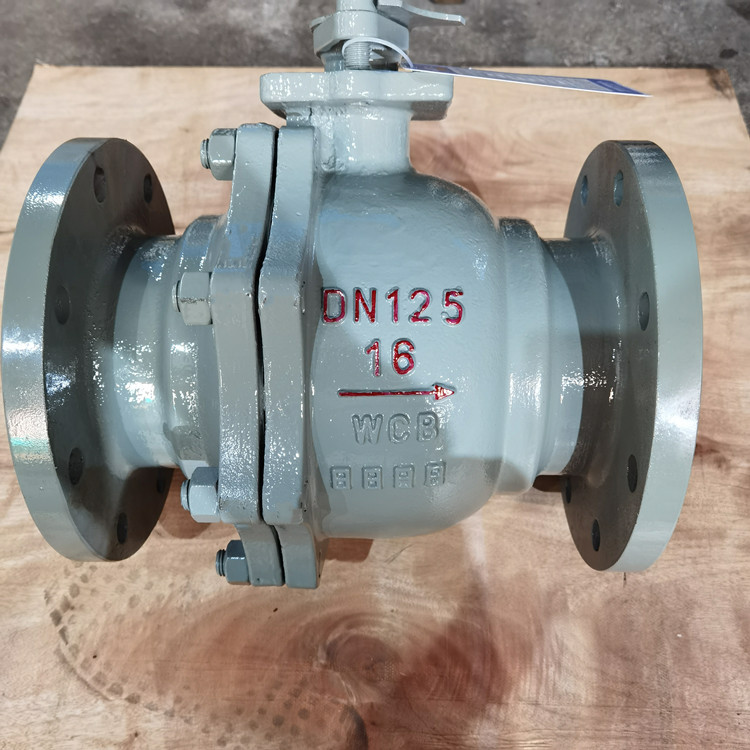

The manufacturing process in an electric actuated butterfly valve factory begins with the selection of high-quality materials, often stainless steel or carbon steel, ensuring durability and resistance to corrosion. The valve body is then fabricated using advanced CNC machines, ensuring precise dimensions and a smooth internal surface to minimize flow resistance. The butterfly disc is meticulously crafted to fit perfectly within the valve body, followed by the attachment of the electric actuator.

Electric actuators, a core component, are designed and assembled separately. They consist of motors, gearboxes, position sensors, and control systems, all integrated to provide accurate positioning and reliable operation. The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve

The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve electric actuated butterfly valve factory.

Quality control is paramount in such a factory. Each valve undergoes rigorous testing, including pressure testing, leakage testing, and operational testing, to ensure it meets industry standards and customer requirements. The factory also emphasizes customization, catering to diverse applications with different pressure ratings, temperature ranges, and control options.

Moreover, these factories are not just about production; they also invest heavily in research and development. Engineers continuously strive to enhance valve designs, improve actuator technology, and integrate smart features like digital communication protocols and diagnostic capabilities. This constant innovation ensures that electric actuated butterfly valves remain at the forefront of fluid control solutions.

In conclusion, the electric actuated butterfly valve factory is a microcosm of modern engineering prowess, combining traditional manufacturing techniques with cutting-edge technology. It's a place where precision meets efficiency, where robustness meets automation, and where reliability meets versatility. As industries continue to evolve, these factories will undoubtedly play an increasingly significant role in shaping the future of process control and automation.

electric actuated butterfly valve factory.

Quality control is paramount in such a factory. Each valve undergoes rigorous testing, including pressure testing, leakage testing, and operational testing, to ensure it meets industry standards and customer requirements. The factory also emphasizes customization, catering to diverse applications with different pressure ratings, temperature ranges, and control options.

Moreover, these factories are not just about production; they also invest heavily in research and development. Engineers continuously strive to enhance valve designs, improve actuator technology, and integrate smart features like digital communication protocols and diagnostic capabilities. This constant innovation ensures that electric actuated butterfly valves remain at the forefront of fluid control solutions.

In conclusion, the electric actuated butterfly valve factory is a microcosm of modern engineering prowess, combining traditional manufacturing techniques with cutting-edge technology. It's a place where precision meets efficiency, where robustness meets automation, and where reliability meets versatility. As industries continue to evolve, these factories will undoubtedly play an increasingly significant role in shaping the future of process control and automation.

The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve

The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve The actuator is then rigorously tested for performance and endurance before being coupled with the butterfly valve electric actuated butterfly valve factory.

Quality control is paramount in such a factory. Each valve undergoes rigorous testing, including pressure testing, leakage testing, and operational testing, to ensure it meets industry standards and customer requirements. The factory also emphasizes customization, catering to diverse applications with different pressure ratings, temperature ranges, and control options.

Moreover, these factories are not just about production; they also invest heavily in research and development. Engineers continuously strive to enhance valve designs, improve actuator technology, and integrate smart features like digital communication protocols and diagnostic capabilities. This constant innovation ensures that electric actuated butterfly valves remain at the forefront of fluid control solutions.

In conclusion, the electric actuated butterfly valve factory is a microcosm of modern engineering prowess, combining traditional manufacturing techniques with cutting-edge technology. It's a place where precision meets efficiency, where robustness meets automation, and where reliability meets versatility. As industries continue to evolve, these factories will undoubtedly play an increasingly significant role in shaping the future of process control and automation.

electric actuated butterfly valve factory.

Quality control is paramount in such a factory. Each valve undergoes rigorous testing, including pressure testing, leakage testing, and operational testing, to ensure it meets industry standards and customer requirements. The factory also emphasizes customization, catering to diverse applications with different pressure ratings, temperature ranges, and control options.

Moreover, these factories are not just about production; they also invest heavily in research and development. Engineers continuously strive to enhance valve designs, improve actuator technology, and integrate smart features like digital communication protocols and diagnostic capabilities. This constant innovation ensures that electric actuated butterfly valves remain at the forefront of fluid control solutions.

In conclusion, the electric actuated butterfly valve factory is a microcosm of modern engineering prowess, combining traditional manufacturing techniques with cutting-edge technology. It's a place where precision meets efficiency, where robustness meets automation, and where reliability meets versatility. As industries continue to evolve, these factories will undoubtedly play an increasingly significant role in shaping the future of process control and automation. Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025