pipe reducers fittings supplier

The Importance of Pipe Reducers and Fittings in Modern Industry

In today’s fast-paced industrial environment, the demand for efficient fluid and gas transportation systems is ever-increasing. One key component that plays a crucial role in these systems is the pipe reducer, along with various types of fittings. Suppliers of pipe reducers and fittings contribute significantly to the infrastructure of industries, ensuring that systems operate flawlessly, safely, and efficiently.

Understanding Pipe Reducers and Fittings

Pipe reducers are essential fixtures used in piping systems to connect pipes of different diameters. They allow for a smooth transition from a larger pipe to a smaller one, facilitating the efficient flow of substances while minimizing turbulence and pressure loss. Pipe reducers are typically made from various materials, including stainless steel, carbon steel, and PVC, offering versatility depending on the application's requirements.

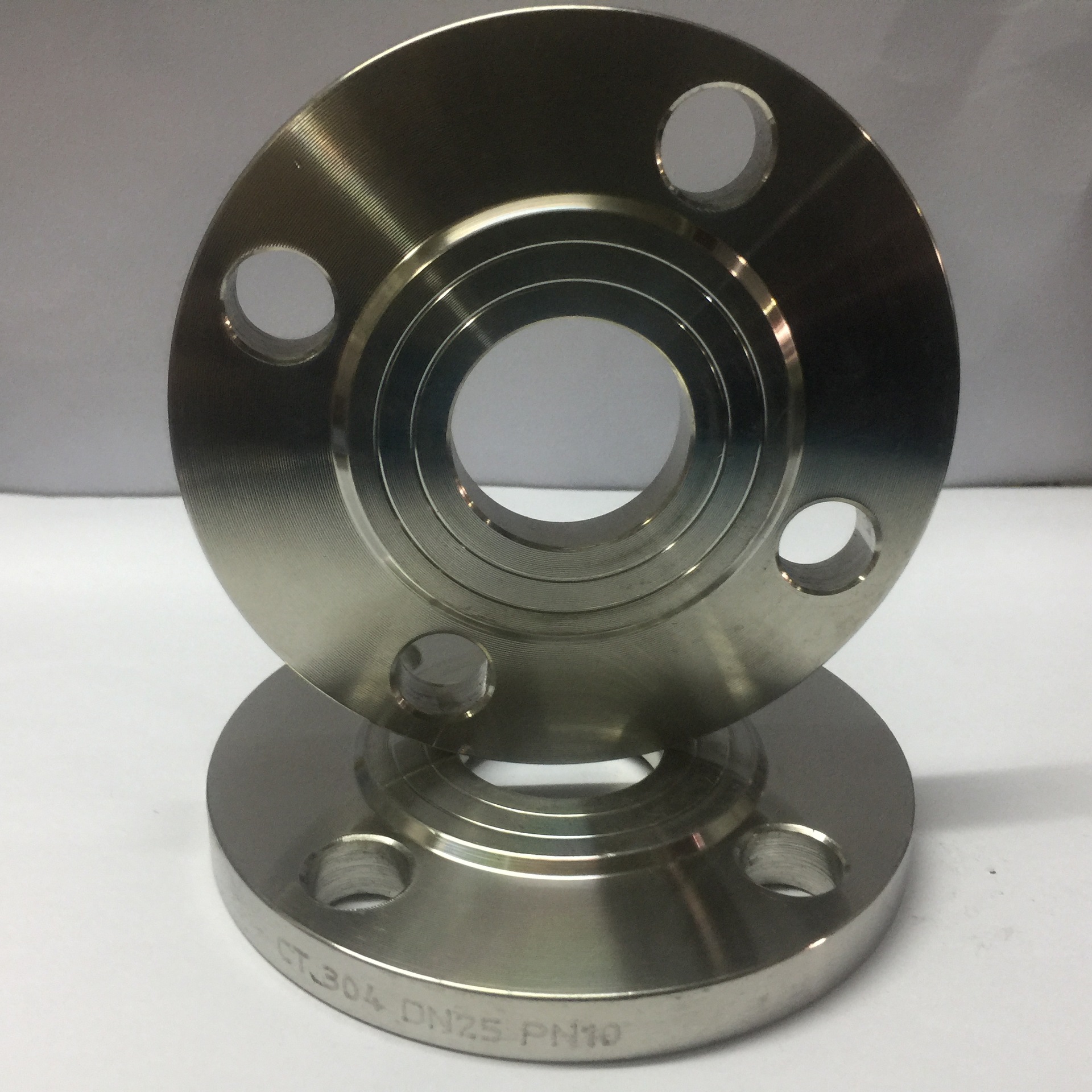

Fittings, on the other hand, refer to a wide range of components, including elbows, tees, couplings, and flanges. These fittings are critical for altering the direction of pipe runs, connecting different sections, and accommodating changes in pressure and temperature. Together, pipe reducers and fittings form the backbone of piping systems across multiple industries, including oil and gas, water treatment, construction, and manufacturing.

The Role of Suppliers

Suppliers of pipe reducers and fittings perform a vital role in ensuring that industries have access to high-quality products. They provide a range of services, from product selection to customization, catering to the specific needs of their clients. A reliable supplier will offer various sizes, materials, and pressure ratings, ensuring that engineers and project managers can find the right components for their projects.

Moreover, the expertise of suppliers can help in guiding clients through the purchasing process. Knowledgeable suppliers can provide insights into the most suitable materials and designs based on the intended application. For instance, in high-temperature environments, suppliers may recommend heat-resistant alloys, while for corroding environments, they might suggest plastic or coated metal fittings.

Quality and Standards

pipe reducers fittings supplier

Quality assurance is paramount in the industry of pipe reducers and fittings. Suppliers must adhere to strict industry standards and regulations to ensure the safety and reliability of their products. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) set forth guidelines to which suppliers must comply.

The best suppliers invest in rigorous testing and quality control procedures. Products are often subjected to pressure tests, chemical analyses, and dimensional inspections to ensure they meet the necessary criteria. When clients purchase from a reputable supplier, they can be assured that the items will perform as expected, reducing the risk of costly leaks or failures.

Customization and Innovation

With the evolving needs of modern industries, the demand for customized pipe reducers and fittings has increased. Suppliers are now offering tailored solutions to meet unique project requirements. This customization can involve altering the dimensions of a reducer or the geometry of a fitting. Advanced manufacturing techniques, such as 3D printing and CNC machining, enable suppliers to produce bespoke components that enhance system performance.

Innovation is another key aspect that suppliers are embracing. The integration of new materials and technologies into their product lines helps address contemporary challenges. For example, suppliers may develop lightweight but durable fittings that reduce transportation costs and installation efforts. Incorporating smart technology into pipe systems can also provide real-time monitoring, enabling better maintenance and reducing downtime.

Conclusion

In summary, suppliers of pipe reducers and fittings are integral to the functionality and efficiency of industrial systems. They not only provide essential components but also offer expertise in selecting and customizing products that meet specific needs. Ensuring product quality and adhering to industry standards are critical responsibilities that suppliers uphold, supporting the safety and reliability of piping systems across various sectors.

As industries continue to innovate and evolve, the role of these suppliers will remain crucial. Their ability to adapt to changing needs, introduce new materials and technologies, and provide customized solutions will play a significant part in shaping the future of fluid and gas transportation systems. Investing in high-quality pipe reducers and fittings from reputable suppliers is essential for any organization looking to enhance its operational efficiency and maintain robust, dependable systems.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025