pn16 globe valve manufacturer

Understanding PN16 Globe Valve Manufacturers

In the world of industrial piping and fluid control, the choice of valves plays a crucial role in ensuring efficiency, safety, and reliability. Among various types of valves, globe valves are particularly valued for their ability to regulate flow effectively. A prominent rating associated with these valves is the PN16 designation, which indicates the pressure handling capability of the valve. In this article, we will explore what PN16 globe valves are, their applications, and what to consider when choosing a reliable manufacturer.

What is a PN16 Globe Valve?

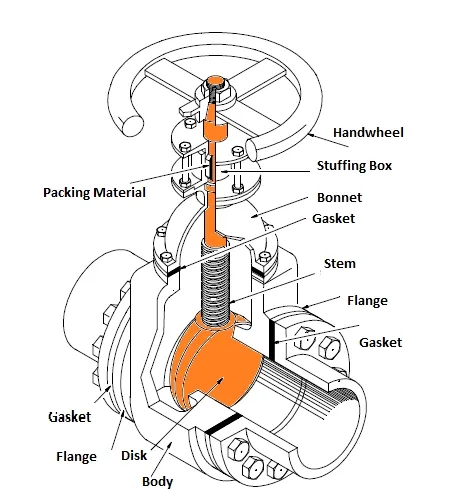

PN stands for Pressure Nominal, a European standard that indicates the maximum pressure the valve can handle under specific temperature conditions. A PN16 globe valve is rated to withstand a maximum pressure of 16 bar (approximately 232 psi). Globe valves are designed with a spherical body and a movable disk, allowing for effective flow regulation by varying the opening size. This type of valve is particularly advantageous when precise control of flow is necessary, making it ideal for throttling applications.

Applications of PN16 Globe Valves

PN16 globe valves are commonly used in various industries, including

1. Water Treatment They regulate water flow in treatment plants, ensuring consistent filtration and purification processes. 2. Oil and Gas In this sector, globe valves manage the flow of hydrocarbons, providing essential control over extraction and distribution processes. 3. Chemical Processing They help in the regulation of various chemicals, where precise flow control is vital for safety and efficiency. 4. HVAC Systems Used to control heating and cooling water in heating, ventilation, and air conditioning systems, ensuring optimal performance. 5. Power Generation Globe valves play a critical role in steam and water systems in power plants.

Selecting a Reliable PN16 Globe Valve Manufacturer

When it comes to choosing a manufacturer for PN16 globe valves, there are specific factors to consider

pn16 globe valve manufacturer

1. Quality Standards It’s crucial to select manufacturers that adhere to international quality standards, such as ISO 9001. These standards ensure that the valves produced are reliable and meet the required specifications.

2. Material Composition High-quality materials used in valve construction significantly influence performance and longevity. Common materials include cast iron, stainless steel, and brass. Depending on the application, corrosion-resistant materials may be necessary.

3. Testing Procedures A reputable manufacturer will have stringent testing procedures in place to ensure that their valves can handle the designated PN16 pressure rating. Look for manufacturers that conduct hydrostatic testing, leak testing, and performance testing.

4. Customization Options Every industrial application is unique, and sometimes standard valves may not fit specific needs. A good manufacturer should offer customization options tailored to the specific requirements of your project.

5. Certifications and Compliance Check if the manufacturers comply with relevant industry certifications and regulations, which may vary based on geographic location and specific applications.

6. Customer Support and Service A responsive customer service team can be invaluable, especially when issues arise or if you require technical guidance regarding the valve’s performance and compatibility.

7. Reputation in the Industry Research the manufacturer's history and reputation. Customer reviews and testimonials can provide insight into the reliability and performance of their products.

Conclusion

In summary, PN16 globe valves are essential components within numerous industrial applications, offering effective flow regulation and reliable performance. When seeking a manufacturer for these valves, it's vital to consider quality, material options, testing procedures, customization capabilities, certifications, customer support, and overall reputation. By making an informed choice, you can ensure that you are investing in high-quality valves that will meet your operational needs and contribute to the efficiency of your systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025