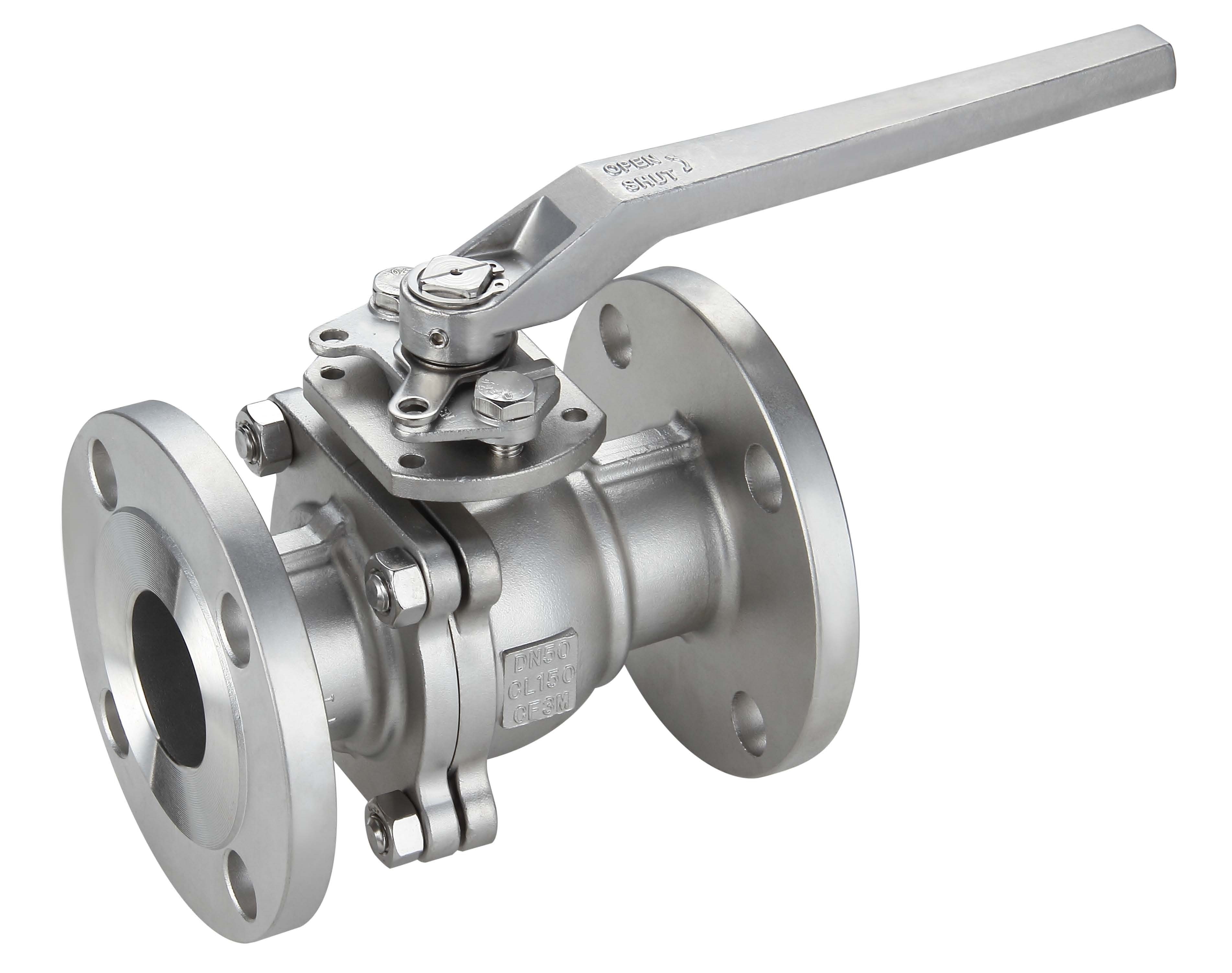

150 gate valve

Understanding the 150% Gate Valve Design, Function, and Applications

In industrial and municipal environments, the efficiency and reliability of fluid control systems are paramount. One key component in these systems is the gate valve, specifically the 150% gate valve. This article delves into the design, functionality, and applications of this valve type, highlighting its significance in various industries.

What is a Gate Valve?

A gate valve is a type of valve used to start or stop the flow of liquids or gases in a pipeline. It features two solid concentric disks, known as gates, that can be moved apart or together to allow or prevent flow. Unlike other types of valves, such as globe or ball valves, gate valves are primarily designed for full flow. When fully opened, they provide minimal resistance to the flow, making them an excellent choice for applications where a straight-line flow is required.

The Concept of 150% in Gate Valves

The term 150% in the context of gate valves often refers to the pressure rating and design specifications that meet the requirements of high-pressure systems. This specification indicates that the valve is capable of withstanding pressures that are 150% greater than the normal working pressure. This enhanced durability ensures that the gate valve remains functional and reliable even under extreme conditions.

Design Features of the 150% Gate Valve

1. Material Selection The materials used in manufacturing gate valves significantly influence their performance. Typically constructed from robust metals like cast iron, stainless steel, or bronze, the choice of material is critical for ensuring the valve can endure high pressures and corrosive environments.

2. Sealing Mechanism The sealing mechanism is another vital feature of gate valves. A well-designed sealing surface prevents leaks and ensures a tight closure when the valve is in the off position. The 150% gate valve often incorporates advanced sealing technologies to enhance its reliability.

3. Operational Mechanism Most gate valves operate using either manual handwheels or automatic actuators. The manual operation allows for precise control, while actuators enable remote operation, enhancing efficiency in complex systems.

4. End Connections Gate valves come in various end connections such as flanged or threaded, making them versatile for different pipeline configurations.

150 gate valve

Applications of 150% Gate Valves

The robust design and high pressure tolerance of the 150% gate valve make it suitable for various applications, including

1. Water Supply Systems In municipal water supply systems, these valves regulate the flow of water, making them essential for maintaining proper pressure and distribution.

2. Oil and Gas Industry The oil and gas sector often operates under extreme conditions, necessitating reliable equipment. The 150% gate valve is regularly used to manage the flow of crude oil and natural gas in pipelines and processing plants.

3. Chemical Processing In chemical processing plants, the valve's ability to handle corrosive fluids and high pressures makes it invaluable for maintaining safety and operational efficiency.

4. Power Generation Power plants rely on various fluid dynamics, and gate valves play a crucial role in managing the flow of cooling water, steam, and other fluids in turbines and boilers.

Benefits of Using a 150% Gate Valve

The advantages of employing a 150% gate valve include

- Durability The robust design ensures longevity, reducing the need for frequent replacements. - Efficiency With a full-flow design, these valves minimize pressure drops, contributing to overall system efficiency. - Versatility Their adaptability to various industries and applications makes them a preferred choice in fluid control systems.

Conclusion

The 150% gate valve is a critical component in the landscape of fluid control technologies. Its design, which accommodates high pressure and ensures reliable performance, makes it indispensable across multiple industries. In applications ranging from municipal water systems to the oil and gas sector, the ability of these valves to facilitate smooth and efficient flow cannot be overstated. As industries continue to evolve, the role of high-performance components like the 150% gate valve will remain central to achieving operational excellence and sustainability.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025