4 inch gate valve

Understanding the 4-Inch Gate Valve Design, Functionality, and Applications

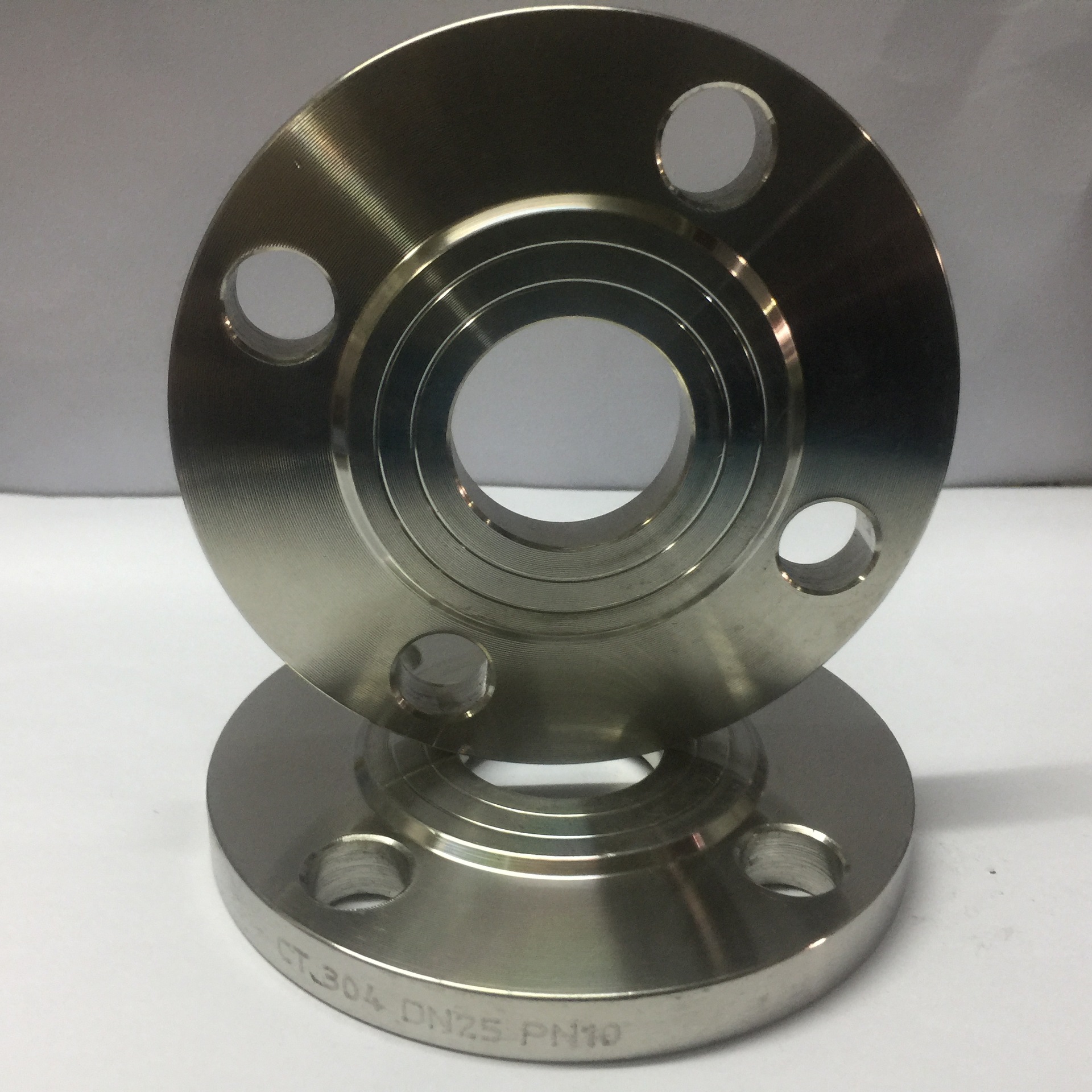

Gate valves are a crucial component in various piping systems, primarily used to control the flow of liquids and gases. Among the different types, the 4-inch gate valve stands out due to its versatility and reliability. Typically made from robust materials such as stainless steel, cast iron, or brass, these valves are designed to provide a tight seal when fully closed, making them ideal for on/off services rather than throttling.

Understanding the 4-Inch Gate Valve Design, Functionality, and Applications

One of the key advantages of the 4-inch gate valve is its ability to handle high pressure and temperature variations. This capability is particularly beneficial in applications such as water supply systems, oil and gas pipelines, and chemical processing plants. Additionally, the relatively small size of the 4-inch valve makes it easy to install and integrate into existing systems, which can save time and reduce costs during maintenance or upgrades.

4 inch gate valve

In terms of specifications, a 4-inch gate valve typically follows industry standards such as ANSI or API, ensuring compatibility and reliability across a range of applications. It is essential to consider factors such as the material of construction, pressure rating, ends type (flanged, threaded, or welded), and temperature ratings when selecting a gate valve for a specific project.

Furthermore, proper installation and maintenance of the valve are crucial for optimal performance. During installation, it is important to ensure that the valve is aligned properly and that all connections are secure to prevent any leaks. Regular inspection and maintenance will prolong the valve’s life and ensure efficient operation. Operators should pay attention to the valve’s performance over time and replace it if any signs of wear or damage are detected.

In conclusion, the 4-inch gate valve is an essential component in many fluid handling systems. Its robust construction, effective sealing capability, and ease of use make it a reliable choice for a wide range of industrial applications. By understanding the design, functionality, and best practices for maintenance, engineers and operators can ensure the longevity and efficiency of the gate valve in their operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025