ଉତ୍ପାଦ ପାରାମିଟରଗୁଡିକ:

| ANSI Pipe Fittings Series Main production materials | |||||

| Material name | |||||

| ASTM A105, 20 #, Q235, 16Mn | |||||

| ASTM A182 F304, F316, 316L, 321 |

| Flange type | Thickness range | Caliber range | Implementation standards | ||||

| elbow | SCH10-SCH160 | 1/2 "-48" | ANSI B16.9 | ||||

| Tee | 1 1/2 "* 1 1/2" -24 "* 18" | ||||||

| Reducer | 1 "* 3/4" -24 "* 22" | ||||||

| Tube cap | 1/2 "-48" |

| ANSI pipe fitting dimensions and connection dimensions | |||||||

| Long radius elbow | |||||||

| ନାମକରଣ ବ୍ୟାସ | (inches) |

Outer diameter | Thickness (mm) | |||||

| D | SCH10 | SCH30 | STD | SCH40 | XS | SCH80 | |

| 1/2 | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 |

| 3/4 | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 |

| 1 | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 |

| 1 1/4 | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 |

| 1 1/2 | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 |

| 2 | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 |

| 2 1/2 | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 |

| 3 | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 |

| 3 1/2 | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 |

| 4 | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 |

| 5 | 141.3 | 3.4 | - | 6.55 | 6.55 | 9.53 | 9.53 |

| 6 | 168.3 | 3.4 | - | 7.11 | 7.11 | 10.97 | 10.97 |

| 8 | 219.1 | 3.76 | 7.04 | 8.18 | 8.18 | 12.7 | 12.7 |

| 10 | 273.1 | 4.19 | 7.8 | 9.27 | 9.27 | 12.7 | 15.09 |

| Tee | ||||||

| ନାମକରଣ ବ୍ୟାସ | (inches) |

Outer diameter | STD | SCH40 | |||

| D1 | D2 | t1 | t2 | t1 | t2 | |

| 1 1/2 * 1 1/2 | 48.3 | 48.3 | 2.77 | 2.77 | 2.77 | 2.77 |

| 2 * 3/4 | 60.3 | 26.7 | 3.91 | 2.87 | 3.91 | 2.87 |

| *1 | - | 33.4 | - | 3.32 | - | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

| * 1 1/2 | - | 48.3 | - | 3.68 | - | 3.68 |

| *2 | - | 60.3 | - | 3.91 | - | 3.91 |

| Tube cap | ||||||

| ନାମକରଣ ବ୍ୟାସ | (inches) |

Outside diameter D | E height | Limit thickness | Height E1 | t | |

| Hidemura | mm | SCH40 | ||||

| 1/2 | 0.84 | 21.34 | 25.4 | 4.57 | 25.4 | 0.109 |

| 3/4 | 1.05 | 26.67 | 25.4 | 3.81 | 25.4 | 0.133 |

| 1 | 1.315 | 33.4 | 38.1 | 4.57 | 38.1 | 0.133 |

| 1 1/4 | 1.66 | 42.2 | 38.1 | 4.83 | 38.1 | 0.14 |

| 1 1/2 | 1.9 | 48.2 | 38.1 | 5.08 | 38.1 | 0.145 |

| 2 | 2.375 | 48.3 | 38.1 | 5.59 | 44.5 | 0.154 |

| Reducer | ||||||

| ନାମକରଣ ବ୍ୟାସ | (inches) |

Outer diameter | STD | SCH40 | |||

| D1 | D2 | t1 | t2 | t1 | t2 | |

| 1 * 3/4 | 33.4 | 26.7 | 3.38 | 2.87 | 3.38 | 2.87 |

| 1 1/2 * 3/4 | 48.3 | 26.7 | 3.68 | 2.87 | 3.68 | 2.87 |

| *1 | - | 33.4 | - | 3.38 | - | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

| 2 * 1 | 60.3 | 33.4 | 3.91 | 3.38 | 3.91 | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

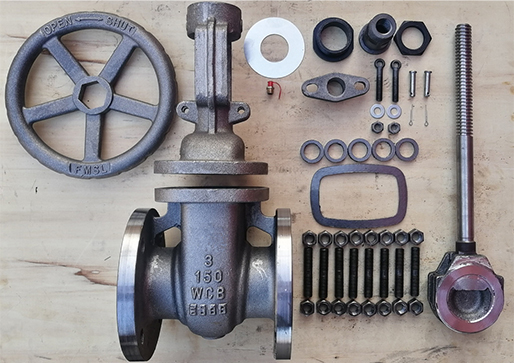

PRODUCT ADVANTAGES:

1. ଆମର ବାଲୁକା କିମ୍ବା ସଠିକ୍ କାଷ୍ଟିଂ ଟେକ୍ନୋଲୋଜି ଅଛି, ତେଣୁ ଆମେ ଆପଣଙ୍କର ଚିତ୍ରାଙ୍କନ ଡିଜାଇନ୍ ଏବଂ ଉତ୍ପାଦନ ଭାବରେ କରିପାରିବା |

2. ଭଲଭ୍ ବଡିରେ ଗ୍ରାହକଙ୍କ ଲୋଗୋ ଉପଲବ୍ଧ |

3. ପ୍ରକ୍ରିୟାକରଣ ପୂର୍ବରୁ ତାପମାତ୍ରା ପ୍ରକ୍ରିୟା ସହିତ ଆମର ସମସ୍ତ କାଷ୍ଟିଂ |

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7. ପ୍ରକାରର ଭାଲ୍ ଆମେ ସାଧାରଣତ Wood ପ୍ୟାକେଜ୍ ପାଇଁ କାଠ କେସ୍ ବ୍ୟବହାର କରୁ, ଆମେ ମଧ୍ୟ ତାହା କରିପାରିବା |

ନିର୍ଦ୍ଦିଷ୍ଟ ଗ୍ରାହକଙ୍କ ଅନୁରୋଧ |

COMPANY ADVANTAGES:

-

1992 ରୁ ଆମେ ନିର୍ମାତା ଅଟୁ |

1992 ରୁ ଆମେ ନିର୍ମାତା ଅଟୁ | -

2.CE, API, ISO ଅନୁମୋଦିତ |

2.CE, API, ISO ଅନୁମୋଦିତ | -

3. ଶୀଘ୍ର ବିତରଣ

3. ଶୀଘ୍ର ବିତରଣ -

4. ଉଚ୍ଚ ଗୁଣ ସହିତ କମ୍ ମୂଲ୍ୟ |

4. ଉଚ୍ଚ ଗୁଣ ସହିତ କମ୍ ମୂଲ୍ୟ | -

5. ବୃତ୍ତିଗତ କାର୍ଯ୍ୟ ଦଳ!

5. ବୃତ୍ତିଗତ କାର୍ଯ୍ୟ ଦଳ!

ତୁମର ବାର୍ତ୍ତା ଏଠାରେ ଲେଖ ଏବଂ ଆମକୁ ପଠାନ୍ତୁ |

ସମ୍ବନ୍ଧିତ products

ସମ୍ବନ୍ଧିତ news