Jan . 29, 2025 00:49

Back to list

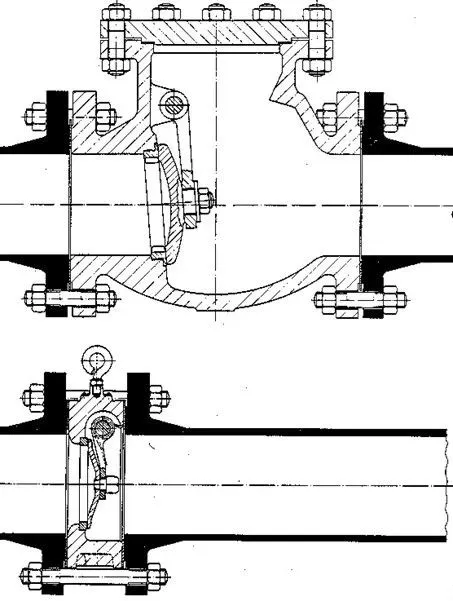

gate valve 2 inch

In the diverse world of industrial plumbing and fluid distribution systems, the 2-inch gate valve stands out as a crucial component that many industries rely upon. Its importance cannot be overstated as it plays a key role in regulating flow, ensuring safety, and enhancing the operational efficiency of various systems.

When considering a purchase of 2-inch gate valves, attention to the various types—such as rising stem, non-rising stem, or wedge types—can further optimize performance for specific use cases. Each offers unique benefits; for instance, while rising stem valves provide a visual indication of the valve position, non-rising stems are preferable in locations with vertical space constraints. From an authority standpoint, selecting a valve from a reputable manufacturer is crucial. Established names in the industry engineer their products to meet stringent standards, offering warranties and comprehensive technical support. Documentation of certifications and quality compliance further adds layers of trustworthiness, essential for ensuring both safety and uninterrupted operations. It is also important to ensure that the valve meets any relevant industry standards or certifications, such as those from the American Petroleum Institute (API) or the American Society of Mechanical Engineers (ASME). Compliance with these standards ensures that the product has undergone rigorous testing, providing an extra layer of security and reliability. Ultimately, understanding your specific application needs, coupled with informed decision-making, is the cornerstone of optimizing the potential of a 2-inch gate valve. Industry veterans often emphasize the importance of integrating these valves into a broader, well-maintained system to fully reap the long-term rewards of their reliability and performance efficiencies. The 2-inch gate valve remains a cornerstone of various industrial applications due to its combination of reliability, efficiency, and durability. Harnessing its full potential is a matter of selecting the right type for your specific needs, ensuring proper installation and maintenance, and working with trusted manufacturers. Through such informed decisions, industries can ensure the seamless operation of their fluid control systems, assuring safety and efficiency across their operations.

When considering a purchase of 2-inch gate valves, attention to the various types—such as rising stem, non-rising stem, or wedge types—can further optimize performance for specific use cases. Each offers unique benefits; for instance, while rising stem valves provide a visual indication of the valve position, non-rising stems are preferable in locations with vertical space constraints. From an authority standpoint, selecting a valve from a reputable manufacturer is crucial. Established names in the industry engineer their products to meet stringent standards, offering warranties and comprehensive technical support. Documentation of certifications and quality compliance further adds layers of trustworthiness, essential for ensuring both safety and uninterrupted operations. It is also important to ensure that the valve meets any relevant industry standards or certifications, such as those from the American Petroleum Institute (API) or the American Society of Mechanical Engineers (ASME). Compliance with these standards ensures that the product has undergone rigorous testing, providing an extra layer of security and reliability. Ultimately, understanding your specific application needs, coupled with informed decision-making, is the cornerstone of optimizing the potential of a 2-inch gate valve. Industry veterans often emphasize the importance of integrating these valves into a broader, well-maintained system to fully reap the long-term rewards of their reliability and performance efficiencies. The 2-inch gate valve remains a cornerstone of various industrial applications due to its combination of reliability, efficiency, and durability. Harnessing its full potential is a matter of selecting the right type for your specific needs, ensuring proper installation and maintenance, and working with trusted manufacturers. Through such informed decisions, industries can ensure the seamless operation of their fluid control systems, assuring safety and efficiency across their operations.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025