Top Manufacturers of 1500 Globe Valves for Industrial Applications

Globe Valve 1500 Manufacturers A Comprehensive Overview

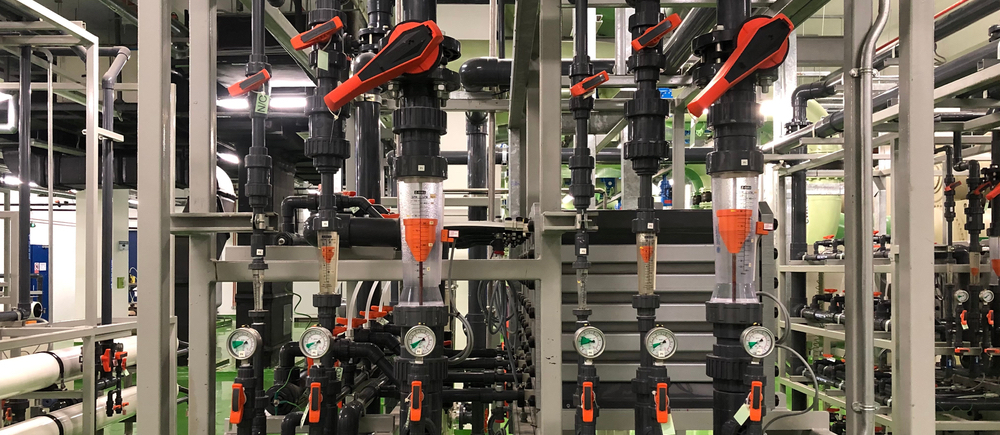

Globe valves are widely recognized for their ability to control flow in piping systems, and they are essential components in various industrial applications. Among the many types of valves, the globe valve is favored for its superior throttling abilities. Specifically, 1500-lb globe valves are designed to withstand high pressures and temperatures, making them an ideal choice for demanding environments. This article explores the significance of globe valve 1500 manufacturers and their role in ensuring quality and reliability.

One of the primary aspects to consider when evaluating globe valve manufacturers is the industry standards they adhere to. Leading manufacturers typically comply with rigorous international certifications such as ANSI, API, and ISO. This compliance guarantees that the valves produced meet specific performance and safety requirements, which is crucial for applications in sectors such as oil and gas, chemical processing, and power generation. Companies that prioritize quality assurance and meticulous testing protocols often stand out as reputable globe valve manufacturers.

Another important factor is the materials used in the production of 1500-lb globe valves. Manufacturers rely on durable materials such as stainless steel, carbon steel, and alloy steel, each offering distinct advantages depending on the application. For instance, stainless steel valves are highly resistant to corrosion, making them suitable for aggressive media, while carbon steel valves are often more cost-effective for standard applications. Competent manufacturers provide a range of material options to cater to diverse industry needs.

globe valve 1500 manufacturers

Furthermore, advancements in technology have a significant impact on the manufacturing processes of globe valves. Many manufacturers are now incorporating computer-aided design (CAD) and finite element analysis (FEA) to enhance the precision and efficiency of their products. These technologies aid in optimizing the design for better performance while also reducing production time and costs. Manufacturers that embrace innovation are more likely to produce high-quality globe valves that meet today's demanding industrial standards.

In addition to product quality, customer service and support play a crucial role in the performance of globe valve 1500 manufacturers. Reliable manufacturers offer extensive technical support, ensuring that clients can navigate installation, maintenance, and troubleshooting effectively. Providing clear and accessible documentation, along with responsive customer service, leads to a better overall experience for the user.

In conclusion, selecting the right globe valve 1500 manufacturer is vital for ensuring optimal performance in industrial applications. By focusing on quality standards, material choices, technological advancements, and excellent customer support, manufacturers contribute to the reliability and efficiency of flow control systems. As industries continue to evolve, the demand for high-quality globe valves will remain paramount, making it essential for manufacturers to uphold the highest standards in their products and services.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025