Feb . 14, 2025 16:39

Back to list

20mm pipe fittings

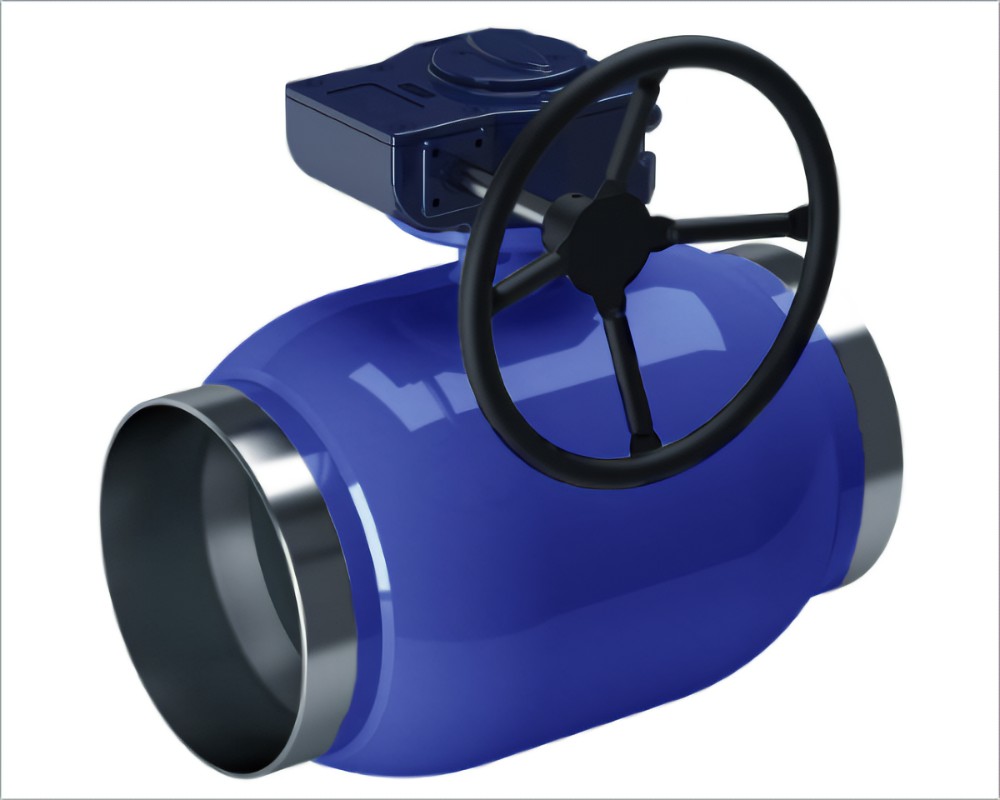

Selecting the right valves and pipe fittings is crucial for the efficiency and longevity of any plumbing or industrial system. Quality, performance, and compatibility must be prioritized, which demands a profound understanding of the components. Valves and pipe fittings, often overlooked as mere connectors or flow regulators, play a pivotal role in fluid dynamics and system efficiency. With years of experience and industry expertise, we provide an authoritative guide to achieving optimal configurations in your applications.

Developing expertise extends beyond understanding product specifications; it involves staying abreast of technological advancements and regulatory standards. The advent of smart valves, with remote monitoring capabilities, transforms conventional systems into intelligent networks, enhancing operational efficiency and predictive maintenance. Meanwhile, adherence to industry standards such as ASME, ANSI, and ISO ensures compliance and quality assurance. Authoritative insight encompasses leveraging professional networks and engaging with industry leaders to share knowledge and discover innovations. Participating in forums, attending conferences, and contributing to specialized publications fortify a reputation of trustworthiness and expertise. Transparent communication with manufacturers and suppliers consolidates an authoritative stance. Detailed discussions regarding product performance, warranty, and after-sales support underpin informed decision-making, cultivating a reliable supplier-client relationship. In conclusion, mastering the art of selecting valves and pipe fittings involves a delicate balance of experience, expertise, authoritativeness, and trustworthiness. Each decision carries the weight of operational efficiency, safety, and cost-effectiveness. With the right approach, one can navigate the complexities of fluid systems, ensuring peak performance and long-term reliability. Embrace innovation, adhere to standards, and maintain rigorous practices to harness the full potential of valves and pipe fittings in any application.

Developing expertise extends beyond understanding product specifications; it involves staying abreast of technological advancements and regulatory standards. The advent of smart valves, with remote monitoring capabilities, transforms conventional systems into intelligent networks, enhancing operational efficiency and predictive maintenance. Meanwhile, adherence to industry standards such as ASME, ANSI, and ISO ensures compliance and quality assurance. Authoritative insight encompasses leveraging professional networks and engaging with industry leaders to share knowledge and discover innovations. Participating in forums, attending conferences, and contributing to specialized publications fortify a reputation of trustworthiness and expertise. Transparent communication with manufacturers and suppliers consolidates an authoritative stance. Detailed discussions regarding product performance, warranty, and after-sales support underpin informed decision-making, cultivating a reliable supplier-client relationship. In conclusion, mastering the art of selecting valves and pipe fittings involves a delicate balance of experience, expertise, authoritativeness, and trustworthiness. Each decision carries the weight of operational efficiency, safety, and cost-effectiveness. With the right approach, one can navigate the complexities of fluid systems, ensuring peak performance and long-term reliability. Embrace innovation, adhere to standards, and maintain rigorous practices to harness the full potential of valves and pipe fittings in any application.

Next:

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025