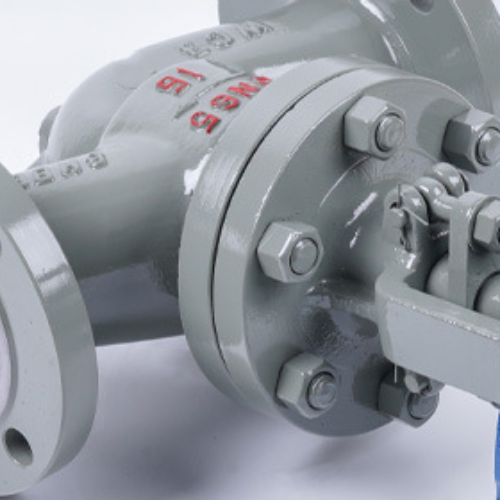

8-inch Flanged Swing Check Valve for Efficient Flow Control Applications

Understanding 8% Flanged Swing Check Valves Design, Functionality, and Applications

Check valves are essential components in various piping systems, ensuring the unidirectional flow of fluids and preventing backflow, which can lead to system failures and equipment damage. Among the various types of check valves available, the flanged swing check valve stands out due to its robust design and efficiency, particularly in industrial applications.

Design and Structure

The flanged swing check valve is characterized by its flanged ends that allow for secure bolting to the piping system. This design facilitates easy installation and maintenance, making it a popular choice in many industries. The valve features a disc that swings open or closed based on the direction of fluid flow. When fluid flows in the intended direction, the disc lifts, allowing passage. Conversely, if the flow attempts to reverse, the disc gravity drops to close the valve, effectively preventing backflow.

Material Selection

The construction materials for flanged swing check valves are critical for their performance and longevity. Common materials include cast iron, stainless steel, and bronze. The material selection often depends on the application requirements, particularly the types of fluids being handled, pressure levels, and temperature ranges. For example, stainless steel is favored for corrosive environments due to its resistance to oxidation and chemical reactions.

Operational Efficiency

8 flanged swing check valve

Flanged swing check valves are known for their low-pressure drop characteristics, making them an efficient option for fluid control. Their design allows for a smooth transition of flow, minimizing turbulence and energy loss. Moreover, the disc design ensures that the valve closes quickly when backflow is detected, further enhancing the system's efficiency and reliability.

Applications

These valves are widely used in various sectors, including water treatment plants, wastewater management, chemical processing, oil and gas, and HVAC applications. In water treatment, flanged swing check valves help maintain the integrity of the systems by preventing contamination due to backflow. In chemical processing, they safeguard against the reverse flow of potentially hazardous materials, thereby protecting both equipment and personnel.

Installation and Maintenance

The ease of installation provided by the flanged design is one of the primary advantages of these valves. Flanged swing check valves can be bolted into place, eliminating the need for welds or complicated fittings. However, proper alignment and gasket sealing are essential to prevent leaks. Routine maintenance involves inspecting the valve for wear and tear, ensuring that the disc operates smoothly and that there are no blockages in the flow path.

Conclusion

In summary, the 8% flanged swing check valve is a crucial component in many fluid handling systems. Its robust design, ease of installation, and efficient operation make it an invaluable asset in preventing backflow and maintaining flow integrity. Understanding the functionalities and applications of these valves can greatly enhance the reliability and longevity of piping systems across various industries. As technology advances, the design and materials used for flanged swing check valves will continue to evolve, further improving their performance and applicability in diverse environments.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025