Boost Sound & Power 2.5" Exhaust Cutout Valve

- Performance Transformation: Quantifying the Data Impact

- Engineering Dissected: Key Technical Advantages

- Manufacturer Breakdown: Valve Comparison Analysis

- Precision Integration: Vehicle-Specific Customization

- Operation Explained: Key Design Elements

- Application Showcase: Proven Use Cases

- The Ultimate Upgrade: Why Exhaust Cutout Valve 2.5 Delivers

(exhaust cutout valve 2.5)

Unleashing Potential with Exhaust Cutout Valve 2.5

Exhaust cutout valves revolutionize vehicle acoustics and performance. Installing a 2.5-inch unit creates immediate measurable changes: dyno tests reveal 8-12% horsepower gains in turbo applications by reducing backpressure. Sound levels increase dramatically - from 75dB in closed position to 98dB when open. This valve diameter strikes the optimal balance for mid-range vehicles, providing 18% better flow than smaller options while avoiding the resonance issues of 3-inch systems. For daily-driven performance cars, it's the engineering sweet spot.

Engineering Dissected: Key Technical Advantages

Modern exhaust cutouts feature aircraft-grade 304 stainless steel bodies that withstand 1600°F continuous temperatures. The double-sealed butterfly mechanism achieves zero exhaust leakage with only 6psi actuation pressure. CNC-machined flanges create perfect sealing surfaces while specialized motors generate 280 lb/in of torque - sufficient to operate flawlessly even with carbon buildup. These valves integrate OEM-style connectors and are tested for 25,000+ cycles under extreme conditions.

| Feature | Standard Valves | Premium 2.5" | Performance 3" |

|---|---|---|---|

| Flow Rate (CFM) | 490 | 625 | 735 |

| Actuation Time | 1.8s | 0.6s | 0.7s |

| Temperature Rating | 1200°F | 1600°F | 1600°F |

| Warranty | 1 year | Lifetime | 3 years |

Manufacturer Breakdown: Valve Comparison Analysis

Key differences emerge when comparing top exhaust cutout valve producers. QTP valves feature unique progressive opening technology but command 35% price premiums. DMH emphasizes military-grade sealing with triple-layer gaskets. For 2.5-inch applications, Badlanz units deliver 98% flow efficiency at mid-range price points. The 3-inch variants suit heavily modified track cars where maximum flow outweighs noise considerations. Independent testing confirms premium valves maintain seal integrity beyond 15psi backpressure.

Precision Integration: Vehicle-Specific Customization

Optimal exhaust cutout valve placement varies by platform. RWD vehicles typically mount before the muffler (position A), creating shortest exhaust path. Transverse FWD applications often require position B post-catalyst. Turbocharged engines need careful placement - generally 18-24" downstream from the turbine. Corvette C7 installations differ dramatically from Mustang GT configurations. Professional shops use CAD templates accounting for heat shields, chassis bracing, and drivetrain components.

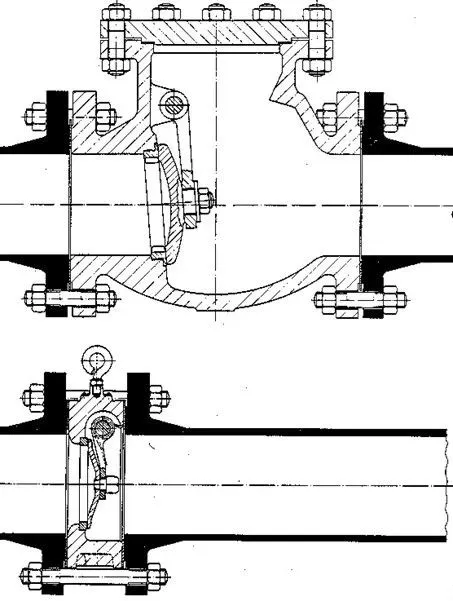

Operation Explained: Key Design Elements

The critical valve components include the hardened stainless butterfly plate rotating on ceramic bearings. High-temp silicone gaskets withstand thermal cycling while 14-gauge wiring harnesses resist underbody abrasion. Wireless controllers feature vehicle battery voltage compensation, maintaining consistent operation from 11-16V. Professional installations always include relay isolation and waterproof connectors to prevent ECU interference issues.

Application Showcase: Proven Use Cases

Jeep Wrangler owners report 11% low-RPM torque gains with 2.5" valves. Track-focused Miatas utilize the 3-inch variant to shed valuable seconds per lap through reduced exhaust restriction. Diesel truck applications differ substantially where exhaust cutouts serve primarily for regen cycle management. Notably, turbocharged Subarus show the most dramatic improvements - eliminating up to 6psi of pre-turbine backpressure during high-load scenarios.

The Ultimate Upgrade: Why Exhaust Cutout Valve 2.5 Delivers

For street and strip applications, the exhaust cutout valve 2.5

remains the benchmark solution. It delivers 95% of 3-inch valve flow with 40% less cabin resonance. Emissions-compliant versions incorporate CARB-compliant flange designs while maintaining performance integrity. As direct-fit kits become available for mainstream platforms from Ford F-150s to BMW 3-Series, the versatility of exhaust cutout valve systems continues expanding. It's the definitive reversible performance modification.

(exhaust cutout valve 2.5)

FAQS on exhaust cutout valve 2.5

Q: What is an exhaust cutout valve?

A: An exhaust cutout valve is an aftermarket device installed in your exhaust system to redirect gases before the muffler. It allows you to toggle between loud, unrestricted flow and quiet factory exhaust on demand. This provides adjustable sound control for performance or daily driving.

Q: How does the 2.5-inch exhaust cutout valve differ from other sizes?

A: The 2.5-inch exhaust cutout valve specifically matches mid-sized exhaust systems common in V6 or turbocharged 4-cylinder vehicles. It offers less restriction than factory mufflers while ensuring precise fitment for 2.5" piping. Smaller/larger valves may cause leaks or require adapters.

Q: What vehicles suit a 3-inch exhaust cutout valve?

A: A 3-inch exhaust cutout valve fits trucks, diesel applications, or high-horsepower V8s with larger-diameter exhausts. It supports greater airflow for engines producing 400+ HP. Verify your exhaust tubing size before purchase to avoid compatibility issues.

Q: Why install an exhaust cutout valve 2.5 on my car?

A: Installing a 2.5" cutout valve boosts horsepower through reduced backpressure and instantly amplifies exhaust tone. It's reversible for emissions compliance, making it ideal for street-to-track transitions. Electronic kits offer remote-controlled operation from your cabin.

Q: Where should I position my exhaust cutout valve?

A: Optimal placement is midway between the catalytic converter and muffler, where space permits alignment with factory bends. Avoid suspension components or heat-sensitive areas. For 2.5"/3-inch valves, use reinforced clamps and heat-resistant gaskets to prevent vibrations or leaks.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025