Flanged Gate Valve with 3% Performance Efficiency for Industrial Applications

Understanding the 3% Gate Valve Flanged A Comprehensive Overview

Gate valves are critical components in various industrial applications. Among the different types of gate valves, the 3% gate valve flanged stands out as a particularly functional and reliable choice. This article aims to delve into the characteristics, advantages, applications, and maintenance aspects of flanged gate valves with a 3% opening, providing insights into their crucial role in fluid control systems.

What is a 3% Gate Valve Flanged?

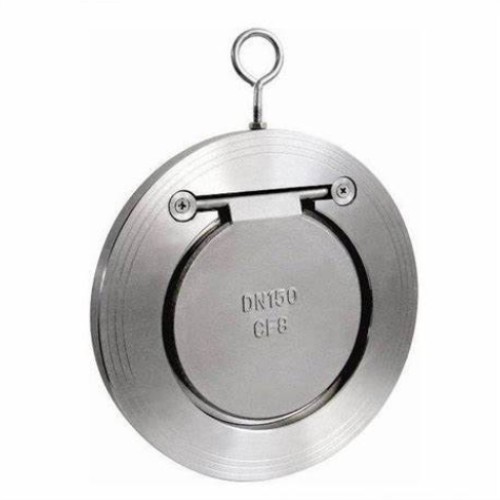

A gate valve is designed to provide a straight-line flow of fluid with minimal resistance when in the fully open position. The 3% in the term refers to the valve's flow control capacity, indicating that when the valve is slightly opened, approximately 3% of the maximum flow rate can pass through, which is essential in applications requiring precise flow control. A flanged connection means that the valve is designed with flanges on either end, allowing for easy installation and maintenance. These flanged connections are typically standardized to facilitate compatibility with piping systems.

Characteristics of 3% Gate Valve Flanged

1. Design and Materials 3% gate valves are often constructed from materials like stainless steel, cast iron, or carbon steel, ensuring durability and resistance to corrosion. The design can incorporate different types of sealing mechanisms, such as resilient and metal-to-metal seals, to prevent leaks.

2. Flow Control The ability to control flow is one of the standout features of a 3% gate valve. By partially opening the gate, operators can regulate the fluid flow as needed. This precision is crucial in various processes, especially in industries like chemicals, oil and gas, and water treatment.

3. Pressure Ratings These valves typically come with various pressure ratings, making them suitable for high-pressure applications. Understanding the pressure requirements is vital when selecting the appropriate valve type for a system.

Advantages of Using 3% Gate Valve Flanged

1. Minimal Pressure Drop When fully opened, gate valves offer an unobstructed passage for the fluid, resulting in a minimal pressure drop. This is particularly beneficial in systems where maintaining pressure is critical.

3 gate valve flanged

2. Versatility Flanged gate valves can accommodate various pipe sizes and configurations, making them versatile for different industrial setups and applications.

3. Ease of Maintenance The flanged design allows for easier installation and removal of the valve compared to other connection types. This ease of maintenance is a significant advantage in reducing downtime during servicing.

4. Durability Constructed from robust materials, flanged gate valves can withstand harsh operating conditions, including high temperatures and pressures, making them a reliable choice for industrial applications.

Applications of 3% Gate Valve Flanged

Flanged gate valves are widely used across multiple industries. Some common applications include

- Water Treatment Managing the flow of water in treatment plants, ensuring accurate control during purification processes. - Oil and Gas Facilitating precise flow control in pipelines and refineries, essential for operational efficiency. - Chemical Manufacturing Regulating the flow of various chemicals in processing plants, often under stringent conditions.

Maintenance Considerations

Regular maintenance of gate valves is crucial to ensure optimal performance. Routine checks for leaks, seal integrity, and operational functionality should be conducted. Lubrication of moving parts and inspection of the flanged connections can help to prevent operational failures.

Conclusion

The 3% gate valve flanged is an excellent option for those seeking a reliable and efficient method of fluid control in industrial systems. With its robust design, ease of installation, and precise flow regulation capabilities, it plays a vital role in enhancing operational efficiency across various sectors. Understanding its features and applications allows engineers and operators to make informed decisions, ultimately leading to better maintenance and operational outcomes in fluid management systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025