Jan . 22, 2025 03:15

Back to list

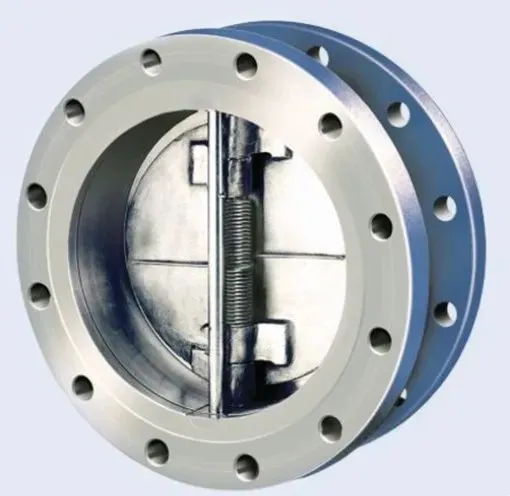

check valve pilot operated

In the intricate world of fluid control systems, pilot operated check valves stand out as a critical component that ensures efficiency, reliability, and safety. These specialized valves offer superior control in a wide range of applications, making them invaluable in industries such as oil and gas, manufacturing, and aerospace.

Authoritativeness in the industry is confirmed by reputable manufacturers who have a long-standing history of producing reliable pilot operated check valves. Companies with ISO certifications and a commitment to quality assurance provide some of the most trustworthy products on the market. Working with such manufacturers affords users the confidence that they are investing in high-quality components that will withstand the test of time. Trustworthiness is also derived from real-world performance and feedback from industry professionals who have implemented pilot operated check valves in their systems. Positive testimonials and case studies from peers in the industry can provide invaluable insights into the effectiveness and reliability of these valves in practical applications. Engaging with expert forums and user groups can also offer guidance and advice on selecting the best valve for your specific needs, ensuring the infrastructure of your system remains robust and dependable. Experience with installing and maintaining pilot operated check valves further enhances their value. These valves are generally straightforward to install and require minimal maintenance, which can result in reduced operational downtime and lower maintenance costs. Regular inspections, however, are recommended to ensure the valves are functioning optimally and to address any issues before they escalate. Pilot operated check valves are undoubtedly an essential component in modern fluid control systems. Their ability to handle high-pressure environments, coupled with precision in operation, makes them a preferred choice for industry professionals seeking reliability and efficiency. As technology continues to evolve, these valves are expected to incorporate even more advanced features, setting new standards for fluid control and management. By investing in high-quality pilot operated check valves, businesses can ensure optimal performance of their fluid systems, safeguarding against potential failures and guaranteeing the longevity of their operations. Manufacturers and engineers dedicated to continuous improvement and innovation in valve technology help drive the industry forward, providing solutions that meet and exceed the demands of modern applications.

Authoritativeness in the industry is confirmed by reputable manufacturers who have a long-standing history of producing reliable pilot operated check valves. Companies with ISO certifications and a commitment to quality assurance provide some of the most trustworthy products on the market. Working with such manufacturers affords users the confidence that they are investing in high-quality components that will withstand the test of time. Trustworthiness is also derived from real-world performance and feedback from industry professionals who have implemented pilot operated check valves in their systems. Positive testimonials and case studies from peers in the industry can provide invaluable insights into the effectiveness and reliability of these valves in practical applications. Engaging with expert forums and user groups can also offer guidance and advice on selecting the best valve for your specific needs, ensuring the infrastructure of your system remains robust and dependable. Experience with installing and maintaining pilot operated check valves further enhances their value. These valves are generally straightforward to install and require minimal maintenance, which can result in reduced operational downtime and lower maintenance costs. Regular inspections, however, are recommended to ensure the valves are functioning optimally and to address any issues before they escalate. Pilot operated check valves are undoubtedly an essential component in modern fluid control systems. Their ability to handle high-pressure environments, coupled with precision in operation, makes them a preferred choice for industry professionals seeking reliability and efficiency. As technology continues to evolve, these valves are expected to incorporate even more advanced features, setting new standards for fluid control and management. By investing in high-quality pilot operated check valves, businesses can ensure optimal performance of their fluid systems, safeguarding against potential failures and guaranteeing the longevity of their operations. Manufacturers and engineers dedicated to continuous improvement and innovation in valve technology help drive the industry forward, providing solutions that meet and exceed the demands of modern applications.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025