Exploring Various Plumbing Connection Methods and Their Applications for Efficient Systems

Understanding Different Types of Plumbing Connections

Plumbing is an essential component of any building, whether it's a home, office, or industrial facility. The connections made throughout the plumbing system play a crucial role in ensuring water flows seamlessly and efficiently. Understanding the different types of plumbing connections can help property owners, maintenance personnel, and contractors make informed choices about their plumbing needs.

Basic Types of Plumbing Connections

1. Soldered Connections

Soldered connections are often used in copper piping systems. This method involves heating the copper pipes until they reach a temperature that allows solder to melt and flow into the joint. Once cooled, the solder solidifies to create a strong, watertight seal. Soldered connections are known for their durability and resistance to leaks. However, they require specialized tools and skills to execute correctly.

2. Compression Connections

Compression connections are frequently used in situations where joining pipes of different materials or diameters is necessary. This type of connection uses a compression nut and ring to create a tight seal when the nut is tightened around the pipe. A significant advantage of compression connections is their ease of installation and removal. They do not require any soldering or gluing, making them an excellent choice for DIY projects.

Threaded connections involve connecting pipes with threads on their ends. These threads can be male or female and are typically used with metal pipes. To ensure a leak-proof seal, a thread sealant or Teflon tape is often applied to the threads before joining the pipes. Threaded connections are straightforward to assemble and disassemble, making them ideal for systems that may need frequent adjustments or repairs.

4. Push-Fit Connections

different types of plumbing connections

Push-fit connections, also known as push-to-connect, are one of the newer innovations in plumbing. This type of connection allows pipes to be easily joined by simply pushing them into a fitting. The inner design of the fitting grips the pipe tightly, creating a secure seal. Push-fit connections are advantageous for quick installations and repairs, as no tools are necessary. However, they may not be suitable for high-pressure systems.

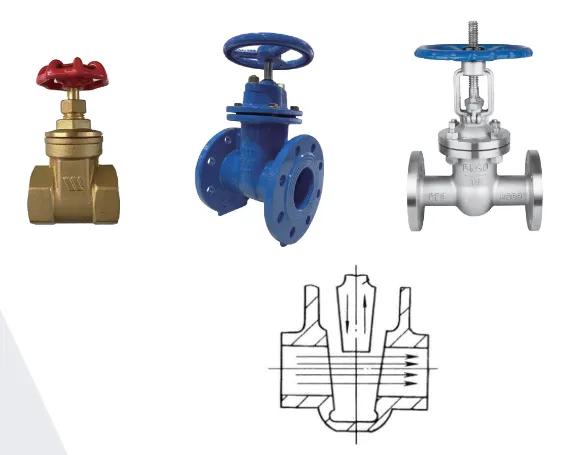

5. Flanged Connections

Flanged connections involve the use of flanges—flat pieces of metal or plastic with holes for bolts—attached to the ends of two pipes. By bolting the flanges together, a robust joint is formed that can withstand significant pressure. Flanged connections are common in industrial settings and are ideal for large-diameter pipes or systems that need to be disassembled frequently for maintenance.

6. PVC and CPVC Connections

For plastic piping systems, such as PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride), solvent welding is a common connection method. This process involves applying a solvent cement to the ends of the pipes and fittings, which softens the plastic and fuses the pieces together as the solvent evaporates. This results in a strong, leak-proof bond ideal for various applications. However, special care must be taken during installation to ensure that the correct solvent is used for the specific material.

Choosing the Right Connection

When deciding on the type of plumbing connection to use, several factors come into play. The material of the pipes, the required pressure rating, the conditions the system will face (such as temperature fluctuations), and the installation environment all influence the choice of connection. Additionally, local building codes and regulations must be adhered to, ensuring safety and compliance.

Conclusion

Understanding the different types of plumbing connections is essential not just for professionals but for anyone managing plumbing systems in their properties. Whether it’s soldered, compression, threaded, push-fit, flanged, or solvent-welded connections, each has its unique strengths and applications. By making informed decisions regarding plumbing connections, property owners can ensure the longevity and efficiency of their plumbing systems, ultimately leading to greater satisfaction and fewer maintenance issues.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025