Top DN 40 Flange Manufacturers and Their Quality Offerings in the Market

DN 40 Flange Manufacturers A Comprehensive Overview

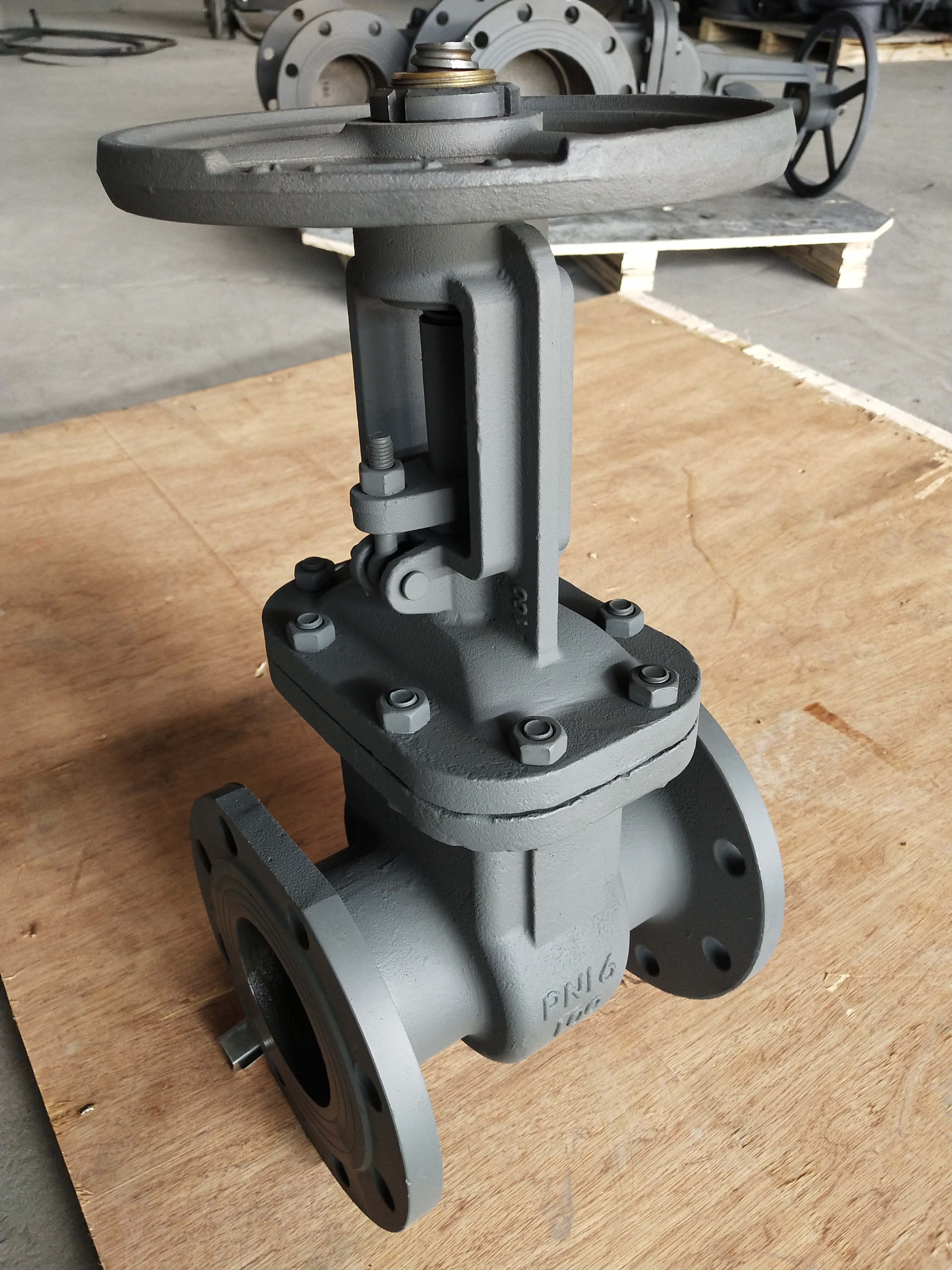

Flanges play a crucial role in ensuring the integrity and quality of piping systems across various industries, including oil and gas, water treatment, and chemical processing. Among the many sizes of flanges, DN 40 flanges are particularly significant due to their versatility and usage in diverse applications. This article will delve into the landscape of DN 40 flange manufacturers, highlighting their importance, characteristics, and selection criteria.

Importance of DN 40 Flanges

The designation DN (Diameter Nominal) indicates the nominal diameter of the flange, which is crucial for compatibility with various piping systems. DN 40 flanges, with a nominal diameter of 40 millimeters, are used in systems requiring medium flow rates and pressures. They are instrumental in connecting pipes, valves, and other equipment to form a complete, efficient pipeline system. The reliability of these flanges is paramount, as any failure can lead to leaks, safety hazards, and operational downtimes.

Types of DN 40 Flanges

DN 40 flanges come in several types, including flat surface, raised face, and blind flanges. The choice of flange type depends on the specific requirements of the application, including pressure ratings, fluid characteristics, and installation constraints. Manufacturers typically offer a range of materials for these flanges, with common options including stainless steel, carbon steel, and PVC. Each material has distinct advantages, such as corrosion resistance for stainless steel or cost-effectiveness for carbon steel.

Leading Manufacturers

dn 40 flange manufacturers

Numerous manufacturers specialize in producing DN 40 flanges. When selecting a supplier, it is essential to consider several factors

1. Quality Assurance Reputable manufacturers adhere to international standards such as ASME, ASTM, and ISO to ensure the quality and safety of their products. Certifications and testing results should be readily available.

2. Customization Options Many industries have unique requirements, which may necessitate customized flanges. Reliable manufacturers offer customization services to meet specific project demands, including alterations in size, material, or design.

3. Supply Chain Reliability Timely delivery and availability of products are crucial for maintaining project timelines. Manufacturers with a robust supply chain can prevent delays and ensure that projects run smoothly.

4. Customer Service Effective communication and support are essential when dealing with any supplier. Manufacturers that offer knowledgeable customer service can assist clients in making informed decisions and provide necessary technical support.

Conclusion

The market for DN 40 flanges is diverse, with numerous manufacturers offering quality products tailored to various industrial applications. As integral components of piping systems, the reliability of these flanges greatly impacts the overall performance and safety of operations. When choosing a DN 40 flange manufacturer, it is imperative to consider quality standards, customization capabilities, supply chain efficiency, and support services. By carefully evaluating these factors, companies can ensure they select the right supplier to meet their specific needs, ultimately contributing to the success of their projects and operations.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025