flanged check valves manufacturer

Flanged Check Valves Understanding the Benefits and Importance in Fluid Systems

Flanged check valves are essential components in the realm of fluid systems, ensuring that the flow of liquids or gases is effectively managed

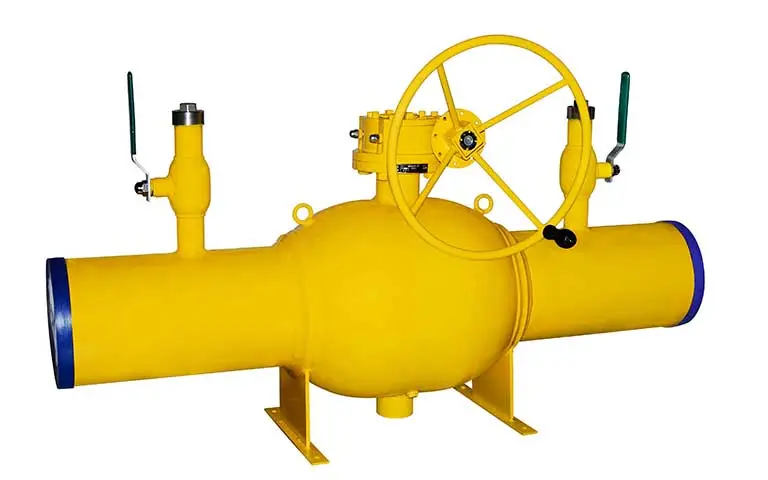

. As a manufacturer of these critical devices, it's important to highlight their design, functionality, and the advantages they offer to various industrial applications.A flanged check valve is designed with flanged connections on either end, allowing for easy installation and maintenance. These valves operate automatically to prevent backflow, ensuring that the medium flows in only one direction. This is crucial in preventing potential system failures or hazards caused by reverse flow, which can lead to contamination, equipment damage, or even catastrophic failures in pipelines.

One of the primary benefits of flanged check valves is their versatility. They are widely used across numerous industries, including water treatment, chemical processing, oil and gas, and HVAC systems. The robust design of these valves allows them to handle a range of pressures and temperatures, making them suitable for both high and low-pressure systems.

Another notable advantage is the ease of installation. The flanged design enables seamless integration into existing piping systems with standard flange connections, reducing installation time and costs. Additionally, their maintenance is straightforward; the ability to quickly detach and reattach the valve minimizes downtime, an essential factor in maximizing operational efficiency.

flanged check valves manufacturer

From a manufacturing perspective, flanged check valves can be constructed from various materials, including stainless steel, cast iron, and duplex. The choice of material is critical as it affects the valve's durability, corrosion resistance, and overall performance. Manufacturers often tailor the construction materials based on the specific needs of the application, ensuring optimal performance and longevity.

Furthermore, these valves are designed for optimal flow characteristics. The internal design minimizes turbulence and pressure drop, allowing for smooth and efficient fluid movement. This attribute enhances the overall efficiency of fluid systems, leading to energy savings and reduced operational costs.

Safety is paramount in any industrial process, and flanged check valves significantly contribute to system integrity. By preventing reverse flow, they protect downstream equipment and maintain the quality of the fluid being transported. This enhances reliability and safety, which are crucial in sectors such as pharmaceuticals or food and beverage manufacturing, where contamination can have dire consequences.

In conclusion, flanged check valves are an indispensable part of fluid management systems. Their ability to prevent backflow, ease of installation, and suitability for various industries make them a preferred choice among manufacturers and engineers alike. With the right application, these valves not only ensure safety and reliability but also enhance the efficiency of fluid systems, contributing to the overall success of industrial operations. As the demand for more efficient and reliable fluid control systems continues to grow, the importance of high-quality flanged check valves cannot be overstated.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025