Jan . 10, 2025 08:55

Back to list

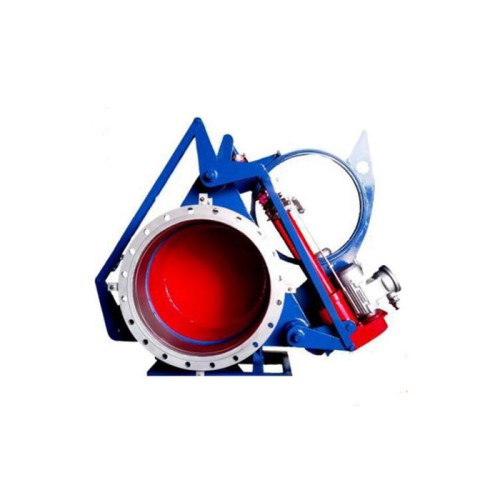

flange gate valve

A flange gate valve plays a crucial role in many industrial applications, providing reliable flow control and ensuring system efficiency. With experience spanning two decades in valve solutions, we've seen the critical need for high-quality, durable flow control mechanisms.

When considering authoritativeness, it’s vital to source flange gate valves from reputable manufacturers known for adhering to international standards such as API, ANSI, and ISO. Ensuring these standards guarantees not only performance but also safety and longevity. Over the years, this industry has seen manufacturers who invest in research and development, bringing innovations such as reduced torque actuators and enhanced sealing technologies. Trustworthiness in the context of flange gate valves extends to the supplier’s after-sales support and adherence to warranty terms. Reliable suppliers offer comprehensive support, including installation guidance, maintenance tips, and quick resolutions to any operational issues. The availability of such support is a testament to a supplier’s confidence in their products and a critical factor in minimizing system downtime. In conclusion, flange gate valves are indispensable in various industrial applications due to their robust design and excellent sealing capabilities. Choosing the right valve involves a blend of experience, expert knowledge, and trust in a supplier who meets high standards of authority in manufacturing. Understanding these elements ensures the selection of a valve that will deliver reliable performance, thereby optimizing your operations and minimizing risks.

When considering authoritativeness, it’s vital to source flange gate valves from reputable manufacturers known for adhering to international standards such as API, ANSI, and ISO. Ensuring these standards guarantees not only performance but also safety and longevity. Over the years, this industry has seen manufacturers who invest in research and development, bringing innovations such as reduced torque actuators and enhanced sealing technologies. Trustworthiness in the context of flange gate valves extends to the supplier’s after-sales support and adherence to warranty terms. Reliable suppliers offer comprehensive support, including installation guidance, maintenance tips, and quick resolutions to any operational issues. The availability of such support is a testament to a supplier’s confidence in their products and a critical factor in minimizing system downtime. In conclusion, flange gate valves are indispensable in various industrial applications due to their robust design and excellent sealing capabilities. Choosing the right valve involves a blend of experience, expert knowledge, and trust in a supplier who meets high standards of authority in manufacturing. Understanding these elements ensures the selection of a valve that will deliver reliable performance, thereby optimizing your operations and minimizing risks.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025