Feb . 07, 2025 02:10

Back to list

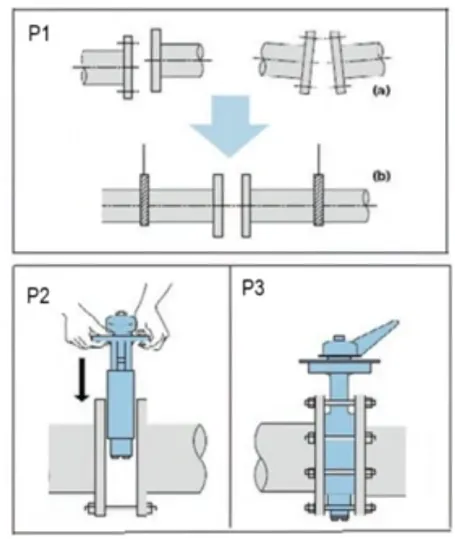

lug type butterfly valve

Lug Type Butterfly Valve Unveiling the Versatile Contender in Fluid Control Systems

Industry experts commend the lug type butterfly valve for its minimalistic yet robust construction. Unlike gate valves, which can be bulky and require significant operational space, butterfly valves offer a compact solution without compromising on performance or durability. Their slim profile and ease of access make them an ideal choice where space constraints are a concern. Moreover, the versatility of the lug type butterfly valve extends to its application in throttling services. The disk's position can be adjusted with precision, controlling flow rates and providing an efficient solution for managing variable flow requirements. This adaptability is crucial for processes that demand precise flow control, underscoring the valve's role in enhancing system performance and stability. The evolution of the lug type butterfly valve is a testament to the ongoing advancements in fluid control technology. Modern designs incorporate innovative features such as leak-proof sealing systems and wear-resistant components, reflecting a commitment to improving valve lifespan and reliability. These improvements further bolster the confidence of industry stakeholders in deploying these valves across critical infrastructures. Research and development in valve manufacturing continue to push the boundaries of what lug type butterfly valves can achieve, with current trends focusing on enhancing automation capabilities and integrating smart sensor technology. These advancements aim to provide real-time monitoring and diagnostics, ensuring proactive maintenance and optimized system management. In terms of authoritativeness, the reputation of leading valve manufacturers in producing high-quality lug type butterfly valves is bolstered by comprehensive warranty offerings and global customer support services. This level of commitment ensures that users have access to the necessary resources and guidance, further solidifying trust in product performance. Overall, the lug type butterfly valve stands out as a dynamic and reliable component in fluid control applications. Its combination of ease of use, adaptability, and robust construction makes it indispensable in modern engineering projects, where performance, efficiency, and cost-effectiveness are paramount. As industries continue to demand innovative solutions, the lug type butterfly valve remains a steadfast contender in achieving unparalleled fluid management excellence.

Industry experts commend the lug type butterfly valve for its minimalistic yet robust construction. Unlike gate valves, which can be bulky and require significant operational space, butterfly valves offer a compact solution without compromising on performance or durability. Their slim profile and ease of access make them an ideal choice where space constraints are a concern. Moreover, the versatility of the lug type butterfly valve extends to its application in throttling services. The disk's position can be adjusted with precision, controlling flow rates and providing an efficient solution for managing variable flow requirements. This adaptability is crucial for processes that demand precise flow control, underscoring the valve's role in enhancing system performance and stability. The evolution of the lug type butterfly valve is a testament to the ongoing advancements in fluid control technology. Modern designs incorporate innovative features such as leak-proof sealing systems and wear-resistant components, reflecting a commitment to improving valve lifespan and reliability. These improvements further bolster the confidence of industry stakeholders in deploying these valves across critical infrastructures. Research and development in valve manufacturing continue to push the boundaries of what lug type butterfly valves can achieve, with current trends focusing on enhancing automation capabilities and integrating smart sensor technology. These advancements aim to provide real-time monitoring and diagnostics, ensuring proactive maintenance and optimized system management. In terms of authoritativeness, the reputation of leading valve manufacturers in producing high-quality lug type butterfly valves is bolstered by comprehensive warranty offerings and global customer support services. This level of commitment ensures that users have access to the necessary resources and guidance, further solidifying trust in product performance. Overall, the lug type butterfly valve stands out as a dynamic and reliable component in fluid control applications. Its combination of ease of use, adaptability, and robust construction makes it indispensable in modern engineering projects, where performance, efficiency, and cost-effectiveness are paramount. As industries continue to demand innovative solutions, the lug type butterfly valve remains a steadfast contender in achieving unparalleled fluid management excellence.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025