Understanding the Specifications and Applications of a Four-Inch Pipe Flange for Fluid Systems

Understanding 4-Inch Pipe Flanges A Comprehensive Overview

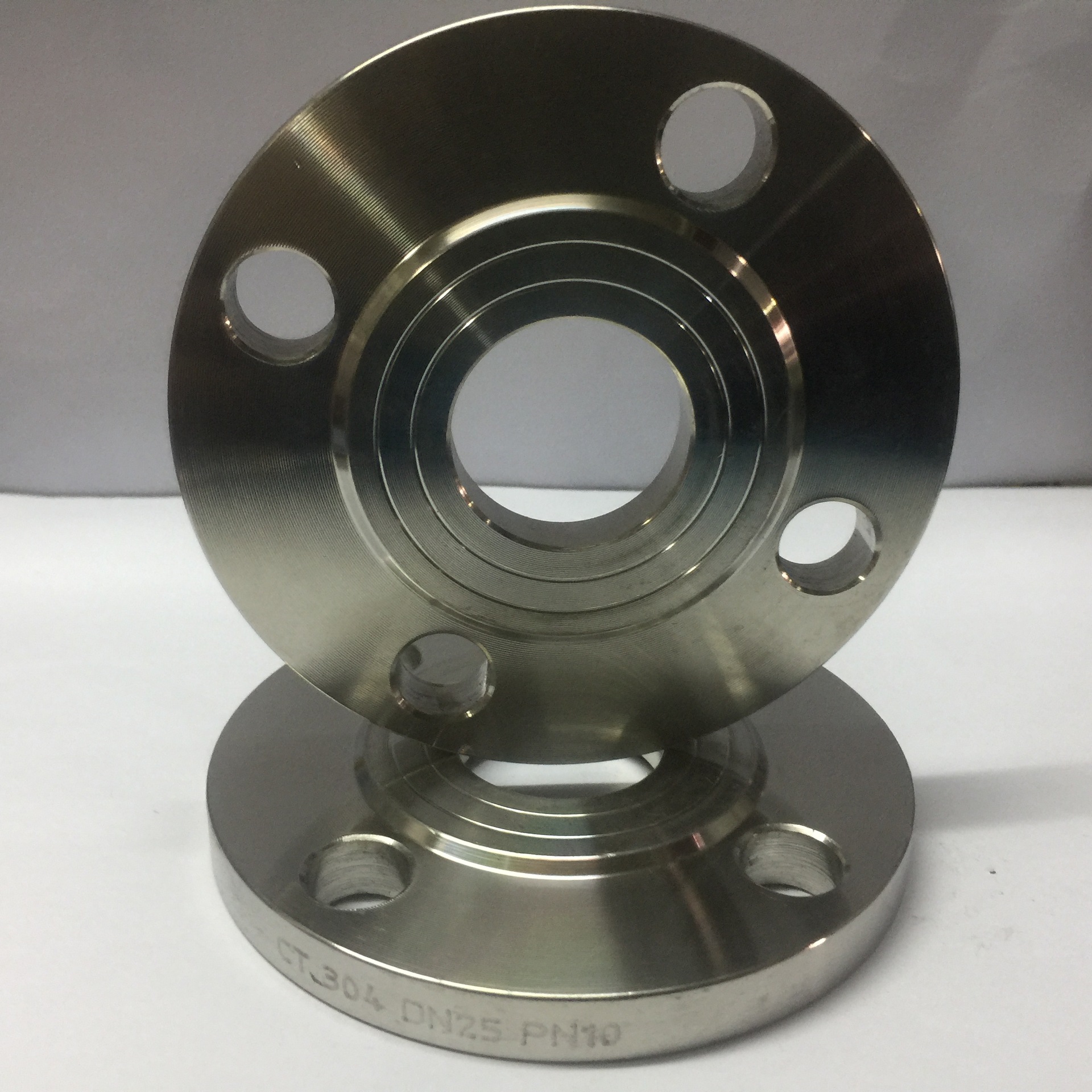

In industrial piping systems, flanges play a pivotal role in connecting pipes, valves, pumps, and other equipment. Among these, the 4-inch pipe flange is a widely used component due to its versatility, ease of installation, and ability to provide a secure seal in various applications. This article will discuss the significance, types, materials, and considerations when working with 4-inch pipe flanges.

Importance of 4-Inch Pipe Flanges

The primary function of a pipe flange is to create a stable connection between two sections of piping. For a 4-inch pipe, flanges facilitate the joining of pipes without the need for welding, making maintenance and repairs more straightforward. This feature is especially beneficial in industries where downtime is costly, as flanged connections can be disassembled and reassembled quickly.

A 4-inch flange can accommodate various pressures and temperatures, depending on its rating. Common flange pressure ratings include ANSI 150, ANSI 300, and ANSI 600, allowing for a range of applications from low-pressure systems to high-pressure environments. Additionally, flanges help in reducing vibration and misalignment in piping systems, enhancing overall operational efficiency.

Types of 4-Inch Pipe Flanges

Flanges come in several types, each designed for specific applications and conditions. The most common types include

1. Weld Neck Flange This type features a long neck that provides strength and stability, making it suitable for high-pressure applications. It is welded to the pipe, creating a robust connection.

2. Slip-On Flange Slip-on flanges are designed to slide over the pipe. They are easier to align and install but may not be suitable for high-pressure scenarios. They require welding on both the inside and outside to secure the connection.

3. Blind Flange A blind flange is a solid disc used to seal the end of a pipe or prevent flow in a system. It is essential in situations where future modifications or inspections may be required.

4. Lap Joint Flange Typically used with a stub end, this flange allows easy disassembly and reassembly, making it ideal for systems that require regular maintenance.

4 inch pipe flange

5. Socket Weld Flange Similar to the slip-on flange, the pipe fits into a socket on the flange, and welding occurs around the joint. This design is often used in high-pressure applications due to its strength.

Materials Used for 4-Inch Pipe Flanges

The choice of material for a 4-inch pipe flange depends on several factors, including the type of fluid being transported, temperature, and pressure conditions. Common materials include

- Carbon Steel Known for its strength and durability, carbon steel is a popular choice for many industrial applications, although it may be susceptible to corrosion without protective coatings.

- Stainless Steel Resistant to corrosion and high temperatures, stainless steel flanges are ideal for chemical processing and food industries.

- Ductile Iron Used in water and wastewater applications, ductile iron flanges provide excellent strength and resistance to wear.

- PVC and CPVC For non-metallic applications, PVC and CPVC flanges are used due to their resistance to chemicals and ease of installation.

Considerations When Using 4-Inch Pipe Flanges

Choosing the right 4-inch pipe flange for your application involves consideration of factors such as pressure, temperature, and the nature of the fluid being transported. Proper alignment and installation are also crucial to prevent leaks and ensure the longevity of the connection. Regular maintenance checks can help detect potential wear or corrosion, allowing for timely replacements and minimizing downtime.

In conclusion, 4-inch pipe flanges are integral components in various piping systems, providing essential connections that facilitate efficient operation. Understanding their types, materials, and proper application is vital for ensuring a reliable and safe piping infrastructure in any industrial setting.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025