A Comprehensive Guide to Selecting the Right Flange for Titan 150 Applications

The Enduring Legacy of the Flange Titan 150

In the realm of industrial engineering, the seamless combination of strength and versatility is paramount. One such embodiment of these characteristics is the Flange Titan 150, a staple in the toolkit of modern industry. This robust and innovative device has transformed the way industries approach flange management, maintenance, and design.

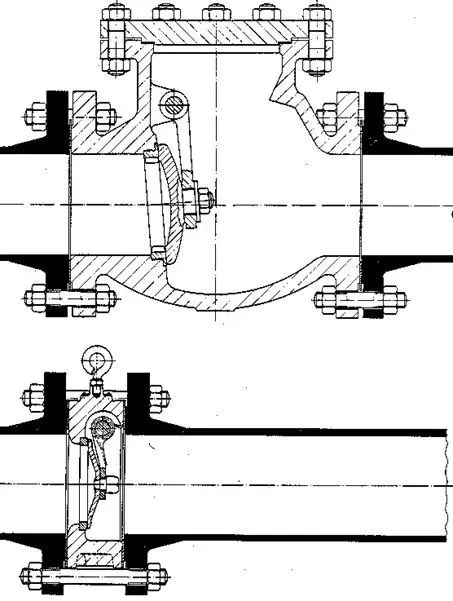

At its core, the Flange Titan 150 is designed to facilitate the handling and assembly of flanges, which are critical components in piping systems. These circular pieces serve as pivotal junctions between pipes, valves, pumps, and other equipment. Given their central role in ensuring system integrity, the efficiency with which flanges can be worked with directly impacts the overall performance of an industrial system.

The Enduring Legacy of the Flange Titan 150

Additionally, the Flange Titan 150 is designed with flexibility in mind. It can accommodate a wide range of flange sizes and configurations, making it suitable for various applications across industries, from oil and gas to manufacturing and beyond. This adaptability not only streamlines the workflow but also reduces the need for multiple tools, saving both time and resources.

flange titan 150

Another hallmark of the Flange Titan 150 is its ease of use. Designed with ergonomics in consideration, operators can handle the device with minimal strain, enhancing safety and efficiency. Quick-release mechanisms and intuitive controls mean that even those new to flange work can achieve proficiency rapidly, making training and skill transition smoother in the workplace.

Beyond operational efficiency, the Flange Titan 150 also champions sustainability. Its design minimizes waste, as it works to reduce the chances of improper flange installation or damage. By ensuring that flanges are correctly aligned and tightened, the potential for leaks and failures decreases, leading to lower maintenance costs and less downtime. This not only benefits the company’s bottom line but also contributes to a lesser environmental impact, aligning with modern sustainability goals.

Furthermore, the Flange Titan 150 is backed by a robust support network, including comprehensive manuals, training programs, and access to expert technicians. This ensures that businesses can maximize the potential of their investment, leading to long-term usage and reliability.

The innovations brought forth by the Flange Titan 150 have garnered attention within the industry, leading to accolades and recognition in engineering circles. As industries evolve and the demand for more efficient, reliable, and sustainable solutions grows, tools like the Flange Titan 150 will undoubtedly remain at the forefront.

In conclusion, the Flange Titan 150 represents more than just a tool; it symbolizes a critical advancement in industrial practices. By enhancing flange handling efficiency, ensuring reliability, and promoting sustainability, it plays a fundamental role in shaping the future of industrial operations. As companies continue to embrace best practices and innovative technologies, tools like the Flange Titan 150 will aid them in navigating the complexities of modern industry with confidence and competence. The legacy of this remarkable device is sure to endure as a cornerstone of excellence in flange management for years to come.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025