Electric Actuated Globe Valve for Precision Flow Control Solutions

The Role of Electric Actuator Globe Valves in Modern Automation

In an era where automation and precision control are critical in numerous industrial applications, electric actuator globe valves have emerged as key components enabling efficient fluid management. The integration of electric actuators with globe valves has revolutionized the way industries handle fluid flow, providing enhanced control, reduced energy consumption, and increased system reliability.

Understanding Electric Actuators

Electric actuators convert electrical energy into mechanical motion, enabling the control of valve openings and closings with remarkable precision. Unlike pneumatic or hydraulic actuators, which rely on compressed air or fluid pressure to operate, electric actuators offer several advantages. They are generally more energy-efficient, reduce operating costs by eliminating the need for HVAC or compressed air systems, and provide more straightforward integration with digital control systems.

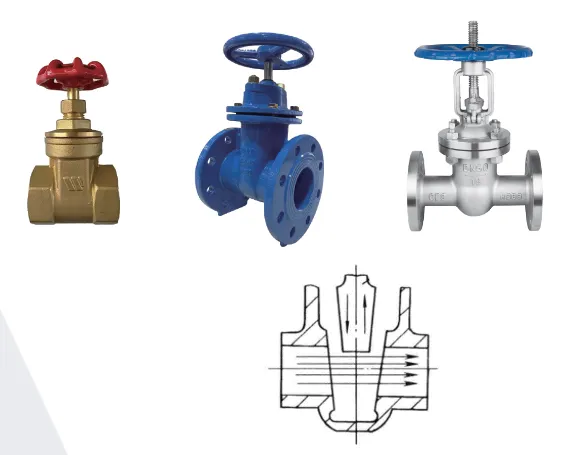

The Globe Valve Mechanism

Globe valves, recognized for their globular body shape, are designed to regulate flow smoothly and efficiently. They consist of a movable disk (or plug) and a stationary ring seat. This design allows for quick shut-off and precise throttling capabilities, making them ideal for flow regulation. The versatility in applications—from water supply systems to chemical processing—underlines the importance of globe valves in various industries.

Integration of Electric Actuators and Globe Valves

The combination of electric actuators and globe valves results in a product that offers both the advantages of electric drive technology and the effective flow control features of globe valves. When integrated, electric actuator globe valves can provide

1. Precise Flow Control Electric actuators allow for fine adjustments to the valve position, ensuring that the flow rates can be precisely controlled. This precision is crucial in applications where the exact flow rate affects product quality or process efficiency.

electric actuator globe valve

2. Remote Operation With electric actuators, globe valves can be operated remotely, enabling control via a centralized process control system. This feature is particularly beneficial in hazardous environments where manual operation poses safety risks.

3. Feedback Mechanisms Many electric actuators come with built-in sensors and feedback mechanisms that provide real-time information about valve position and operation status. This capability enhances the monitoring and diagnostic process, allowing for proactive maintenance and minimizing downtime.

4. Energy Efficiency Electric actuators consume power only when adjusting the valve position, providing significant savings compared to continuous energy consumption methods such as pneumatic systems. This efficiency is particularly relevant in large-scale operations where multiple valves are in use.

5. Simplified Installation and Maintenance Electric actuator globe valves are generally simpler to install and maintain compared to traditional actuation systems. The absence of complex pneumatic lines or hydraulic fluid reservoirs reduces the overall complexity of the installation process.

Applications Across Industries

The versatility of electric actuator globe valves makes them suitable for a wide range of applications across various sectors. In the water treatment industry, they are essential for controlling the flow of water and chemicals during treatment processes. In chemical manufacturing, precise control is vital for ensuring product quality, making electric actuator globe valves an indispensable component. Additionally, the food and beverage sector relies on these valves to meet stringent hygiene and quality standards while ensuring efficient production processes.

Future Trends

As industries continue to embrace digitalization and Industry 4.0 principles, the role of electric actuator globe valves is poised to expand further. Innovations such as IoT-enabled actuators are expected to emerge, allowing for even more sophisticated integration into smart manufacturing systems. Enhanced data analytics capabilities can provide insights into valve performance and operational efficiency, driving continuous improvement initiatives.

In conclusion, electric actuator globe valves represent a significant advancement in the field of fluid control. Their ability to combine precise control with energy efficiency, remote operation, and ease of maintenance makes them crucial in modern industrial applications. As technology advances, these valves will likely play an even more prominent role in the automation landscape, continuing to enhance operational efficiencies across various sectors. As industries strive for better efficiency and sustainability, electric actuator globe valves will undoubtedly remain at the forefront of fluid control solutions.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025