3 inch 204 gate valve specifications and applications for efficient flow control

Understanding the 3 4 Inch Gate Valve Features, Applications, and Benefits

In industrial and municipal applications, valves play a crucial role in controlling the flow of fluids. Amongst various types of valves, gate valves are favored for many applications due to their ability to handle high flow rates with minimal pressure drop. Focusing specifically on the 3 4 inch gate valve, this article delves into its design features, applications, and benefits, while highlighting its significance in modern engineering.

Design Features

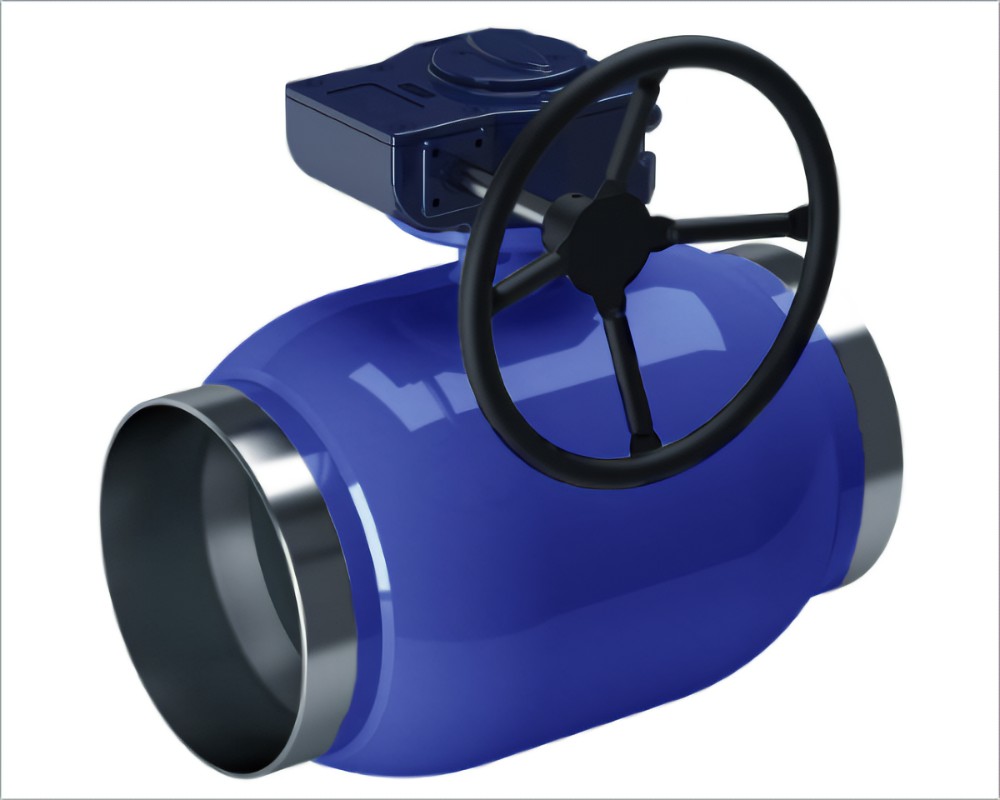

A gate valve is defined by its unique mechanism that allows for full flow with minimal obstruction. The 3 4 inch designation signifies its size—2 inches in diameter—with the “3 ” likely referring to some additional specifications or standards that may relate to pressure ratings, materials, or design specifications. Typically, gate valves are operated using a wheel or lever which, when turned, lifts or lowers a gate into or out of the flow path, allowing fluid to pass through when open.

One of the most notable features of the 3 4 inch gate valve is its construction material, which can vary according to the intended application. Common materials include brass, stainless steel, and cast iron, selected for their resilience against corrosion and wear. Furthermore, the gate valve can have different seat designs, including elastomeric seals or metal-to-metal seating, enhancing its sealing capabilities and longevity.

Moreover, these valves operate under various pressure ratings—often up to 150 psi or more—depending on the specifications. The choice of valve design not only affects performance but also determines its maintenance needs and overall longevity in service.

Applications

The versatility of the 3 4 inch gate valve makes it applicable across numerous industries. It is commonly found in water supply systems, oil and gas pipelines, and chemical processing plants. In municipal applications, these valves regulate the flow of potable water and help manage wastewater systems. Their ability to provide a tight seal when closed makes them an ideal choice for applications where backflow prevention is critical.

3 4 inch gate valve

In the oil and gas industry, gate valves are utilized for on/off control in pipelines and vessels, ensuring that the flow can be effectively interrupted during maintenance or emergency situations. Additionally, they are used in steam systems in power plants where high temperatures and pressures are involved, necessitating durable materials and reliable performance.

Benefits

The primary benefit of a 3 4 inch gate valve lies in its efficiency. When fully opened, it offers minimal resistance to flow, which is a vital characteristic for applications requiring high flow rates. This efficiency not only saves energy but also reduces the operational costs associated with pumping fluids.

Another significant advantage is the straightforward operation of gate valves. Their design enables quick and easy actuation, which is crucial in emergency situations where rapid response is necessary. The maintenance of these valves is generally simple; their design allows for easy access to the internals for cleaning or repairs.

Moreover, the resilience and durability of modern materials used in gate valves ensure long service life with proper maintenance. Many gate valves also come with features like flanged ends, making installation and removal straightforward, further reducing downtime for repairs or replacements.

Conclusion

In summary, the 3 4 inch gate valve is a vital component in various industrial and municipal applications, offering exceptional flow control capabilities. Its robust design, ease of operation, and low-pressure drop make it a preferred choice in situations demanding reliable and efficient fluid management. As industries continue to evolve and emphasize efficiency and safety, the role of the gate valve will remain indispensable. Understanding the technical specifications and applications of this valve can lead to better choices in fluid management systems, ultimately contributing to operational success.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025