stainless steel gate valve manufacturer

The Rise of Stainless Steel Gate Valve Manufacturers

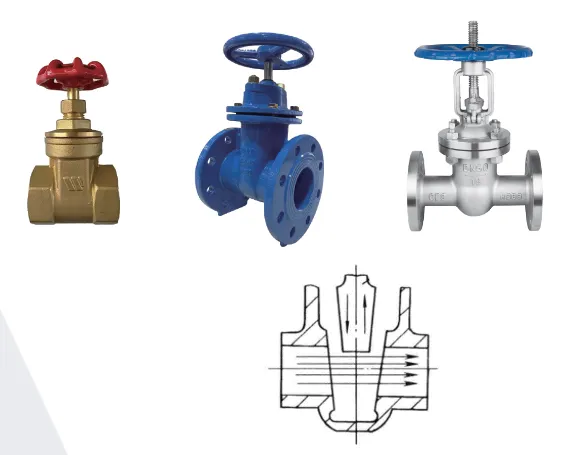

Stainless steel gate valves have become a crucial component in various industrial applications due to their durability, reliability, and resistance to corrosion. With increasing demands in sectors like oil and gas, water treatment, power generation, and chemical processing, the role of stainless steel gate valve manufacturers has grown significantly. This article explores the importance of these manufacturers, the advantages of stainless steel gate valves, and the future trends in this vital industry.

Importance of Stainless Steel Gate Valve Manufacturers

Manufacturers specializing in stainless steel gate valves play a pivotal role in ensuring the availability of high-quality valves for diverse applications. These companies are responsible for designing, producing, and supplying valves that meet specific industry standards and regulations. Whether it is for high-pressure systems in oil refineries or for controlling flow in water systems, the precision and quality of stainless steel gate valves are paramount.

A reliable manufacturer must adhere to strict manufacturing processes, utilize advanced technology, and employ skilled labor to create products that withstand harsh operating conditions. The reputation of a manufacturer is often built on its ability to deliver products that not only meet but exceed industry expectations, thus fostering long-term relationships with clients across various sectors.

Advantages of Stainless Steel Gate Valves

Stainless steel gate valves offer numerous advantages that make them preferable over other materials, such as brass or cast iron. One of the primary benefits is their resistance to corrosion. Stainless steel contains chromium, which forms a protective layer on the surface of the valve, thereby preventing rust and degradation over time, even in challenging environments.

Moreover, stainless steel gate valves provide excellent temperature and pressure endurance, making them suitable for high-stress applications. Their robust construction allows them to handle extreme conditions, ensuring consistent performance and a longer lifespan. This durability leads to reduced maintenance costs and downtime for industries relying on continuously operating systems.

stainless steel gate valve manufacturer

Another significant advantage is the design of gate valves, which allows for unobstructed flow when fully opened. This characteristic minimizes pressure loss and ensures efficient fluid flow, making them ideal for applications where fluid velocity is critical. Furthermore, the low operating torque required to operate a gate valve simplifies installation and maintenance.

Challenges for Manufacturers

Despite the numerous advantages and increasing demand, stainless steel gate valve manufacturers face several challenges. One of the primary challenges is the fluctuation in raw material prices. The cost of stainless steel can be volatile, impacting production costs and pricing for end users. Manufacturers must adopt efficient supply chain management strategies to mitigate these fluctuations.

Additionally, environmental regulations and standards are becoming increasingly stringent. Manufacturers must invest in sustainable practices, such as minimizing waste and emissions during production, to comply with these regulations. Embracing environmentally friendly technologies and materials not only aids compliance but can also enhance a manufacturer’s reputation in the market.

Future Trends in the Industry

Looking ahead, the stainless steel gate valve manufacturing industry is poised for growth, driven by technological advancements and increasing industrialization. The integration of smart technologies, such as IoT and automation, is expected to revolutionize the way valves are monitored and controlled. Smart valves equipped with sensors can provide real-time data on pressure, flow rate, and valve performance, allowing for timely maintenance and enhanced operational efficiency.

Furthermore, the push for sustainable practices will prompt manufacturers to explore eco-friendly materials and production methods. Innovations in recycling and material sourcing will play a key role in shaping the future of the industry.

In conclusion, stainless steel gate valve manufacturers are integral to the success of various industries that rely on efficient and reliable valve solutions. By understanding the advantages of their products, addressing the challenges they face, and embracing future trends, manufacturers can position themselves for lasting success in a competitive market. With continued investment in technology and a commitment to quality, the future of the stainless steel gate valve manufacturing industry looks promising.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025