FAIGA FA'AVAE:

| ANSI Pipe Fittings Series Main production materials | |||||

| Material name | |||||

| ASTM A105, 20 #, Q235, 16Mn | |||||

| ASTM A182 F304, F316, 316L, 321 |

| Flange type | Thickness range | Caliber range | Implementation standards | ||||

| elbow | SCH10-SCH160 | 1/2 "-48" | ANSI B16.9 | ||||

| Tee | 1 1/2 "* 1 1/2" -24 "* 18" | ||||||

| Reducer | 1 "* 3/4" -24 "* 22" | ||||||

| Tube cap | 1/2 "-48" |

| ANSI pipe fitting dimensions and connection dimensions | |||||||

| Long radius elbow | |||||||

| Nominal diameter (inches) |

Outer diameter | Thickness (mm) | |||||

| D | SCH10 | SCH30 | STD | SCH40 | XS | SCH80 | |

| 1/2 | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 |

| 3/4 | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 |

| 1 | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 |

| 1 1/4 | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 |

| 1 1/2 | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 |

| 2 | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 |

| 2 1/2 | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 |

| 3 | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 |

| 3 1/2 | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 |

| 4 | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 |

| 5 | 141.3 | 3.4 | - | 6.55 | 6.55 | 9.53 | 9.53 |

| 6 | 168.3 | 3.4 | - | 7.11 | 7.11 | 10.97 | 10.97 |

| 8 | 219.1 | 3.76 | 7.04 | 8.18 | 8.18 | 12.7 | 12.7 |

| 10 | 273.1 | 4.19 | 7.8 | 9.27 | 9.27 | 12.7 | 15.09 |

| Tee | ||||||

| Nominal diameter (inches) |

Outer diameter | STD | SCH40 | |||

| D1 | D2 | t1 | t2 | t1 | t2 | |

| 1 1/2 * 1 1/2 | 48.3 | 48.3 | 2.77 | 2.77 | 2.77 | 2.77 |

| 2 * 3/4 | 60.3 | 26.7 | 3.91 | 2.87 | 3.91 | 2.87 |

| *1 | - | 33.4 | - | 3.32 | - | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

| * 1 1/2 | - | 48.3 | - | 3.68 | - | 3.68 |

| *2 | - | 60.3 | - | 3.91 | - | 3.91 |

| Tube cap | ||||||

| Nominal diameter (inches) |

Outside diameter D | E height | Limit thickness | Height E1 | t | |

| Hidemura | mm | SCH40 | ||||

| 1/2 | 0.84 | 21.34 | 25.4 | 4.57 | 25.4 | 0.109 |

| 3/4 | 1.05 | 26.67 | 25.4 | 3.81 | 25.4 | 0.133 |

| 1 | 1.315 | 33.4 | 38.1 | 4.57 | 38.1 | 0.133 |

| 1 1/4 | 1.66 | 42.2 | 38.1 | 4.83 | 38.1 | 0.14 |

| 1 1/2 | 1.9 | 48.2 | 38.1 | 5.08 | 38.1 | 0.145 |

| 2 | 2.375 | 48.3 | 38.1 | 5.59 | 44.5 | 0.154 |

| Reducer | ||||||

| Nominal diameter (inches) |

Outer diameter | STD | SCH40 | |||

| D1 | D2 | t1 | t2 | t1 | t2 | |

| 1 * 3/4 | 33.4 | 26.7 | 3.38 | 2.87 | 3.38 | 2.87 |

| 1 1/2 * 3/4 | 48.3 | 26.7 | 3.68 | 2.87 | 3.68 | 2.87 |

| *1 | - | 33.4 | - | 3.38 | - | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

| 2 * 1 | 60.3 | 33.4 | 3.91 | 3.38 | 3.91 | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

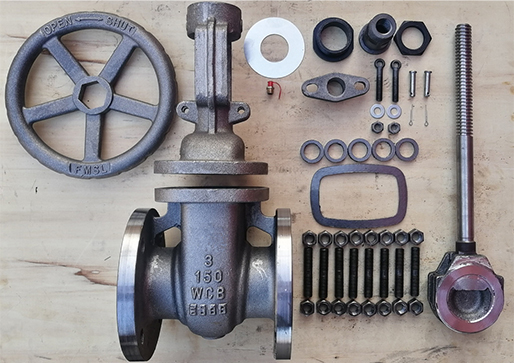

PRODUCT ADVANTAGES:

1. Matou te maua le oneone poʻo le saʻo le faʻaaogaina o tekonolosi, o lea matou te mafaia e pei o lau ata tusi ata ma le gaosiga.

2.Customers 'logo o loʻo avanoa lafo i luga o le tino valve.

3. O a tatou lafo uma ma faiga faʻafefe aʻo leʻi faʻaogaina.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7. Le ituaiga valve e masani ona matou faʻaogaina laupapa laupapa e afifi ai, Matou te mafaia foi e tusa ai

manaoga faapitoa a tagata faatau.

COMPANY ADVANTAGES:

-

1.We gaosi oloa Talu mai 1992.

1.We gaosi oloa Talu mai 1992. -

2.CE, API, ISO faamaonia.

2.CE, API, ISO faamaonia. -

3. Faʻasalalau vave.

3. Faʻasalalau vave. -

4.Low tau ma tulaga maualuga.

4.Low tau ma tulaga maualuga. -

5.Au galuega fa'apolofesa!

5.Au galuega fa'apolofesa!

Tusi lau savali iinei ma lafo mai ia i matou

Fa'atatau products

Fa'atatau news