gate valve sizing

Understanding Gate Valve Sizing A Comprehensive Guide

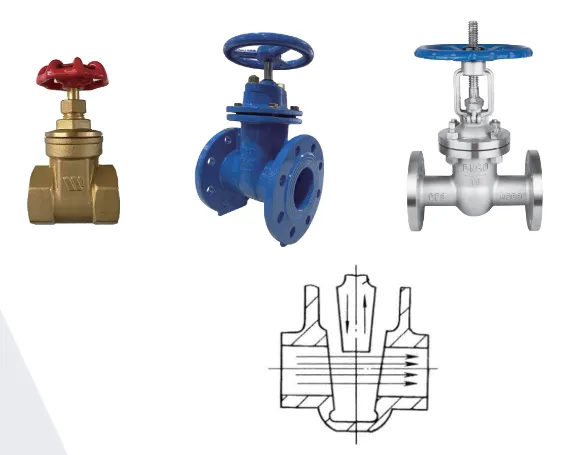

Gate valves are essential components in various industrial applications, serving as on/off control devices that allow for the flow of liquids and gases through pipelines. Proper sizing of gate valves is crucial to ensure optimal performance, efficiency, and safety in any system. In this article, we explore the key factors influencing gate valve sizing, the methods used for sizing, and the implications of incorrect sizing.

Importance of Proper Sizing

The primary purpose of a gate valve is to provide a tight seal when closed and allow unrestricted flow when open. However, the performance of a gate valve can be significantly impacted by its size relative to the pipe diameter and the overall system requirements. Proper sizing is vital to prevent issues such as pressure drops, increased wear and tear, and inefficient system operation.

Factors Influencing Sizing

1. Pipe Diameter The first consideration in gate valve sizing is the diameter of the pipeline it will be installed in. A valve that is too small may restrict flow, causing pressure losses, while an oversized valve can lead to turbulence and inefficient operation.

2. Flow Rate Understanding the required flow rate is critical for sizing. This rate is often determined by the application’s needs, such as the specific process requirements in chemical or water treatment industries.

3. Medium Characteristics The type of fluid (liquid, gas, or slurry) passing through the valve, as well as its temperature, viscosity, and corrosive properties, significantly influence the choice of valve size and design.

4. Pressure Rating The pressure within the system must be considered, as it affects the valve’s performance and longevity. Gate valves must be rated to handle the expected maximum pressure and any potential surges.

gate valve sizing

5. Installation Environment The location and accessibility of the valve may also dictate size choices. Valves in cramped or hazardous environments may need special considerations or adjustments in size.

Sizing Methods

Several methodologies can be employed to size gate valves accurately. One common approach involves using the ANSI (American National Standards Institute) guidelines, which include formulas based on flow rates and pipe diameters. Another method is the use of valve sizing software that incorporates various parameters to calculate optimal valve dimensions.

Additionally, the Cv (flow coefficient) method can be used, where the flow capacity of the valve is calculated based on fluid characteristics and flow conditions. This helps in identifying the valve size that can handle specific flow rates without causing significant pressure drops.

Consequences of Incorrect Sizing

Incorrectly sized gate valves can lead to several operational issues. A valve that is too small can create excessive pressure drops, reducing system efficiency and potentially causing pump cavitation. Conversely, an oversized valve can result in poor flow control and increased operational costs due to energy waste.

Furthermore, frequent maintenance and premature valve failure are common consequences of improper sizing. Such failures can result in unplanned downtime, posing safety risks and increasing operational costs.

Conclusion

In summary, proper sizing of gate valves is paramount to the efficiency and safety of fluid systems. By considering factors such as pipe diameter, flow rate, medium characteristics, pressure ratings, and installation environments, engineers can select the right valve size to meet operational needs. Utilizing established sizing methods and adhering to recognized standards will help ensure that the selected gate valve delivers optimal performance and longevity, ultimately contributing to the reliability of the entire system.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025