High-Quality Stainless Steel Needle Valves for Precision Flow Control Applications

Understanding SS Needle Valves Key Components in Fluid Control

In various industrial applications, the precision and efficiency of fluid control systems are paramount. One critical component that plays a significant role in managing the flow of fluids is the needle valve, particularly those made from stainless steel (SS). This article will delve into the features, advantages, and applications of SS needle valves, highlighting why they are favored in many settings.

What is a Needle Valve?

A needle valve is a type of valve that is used to regulate the flow of liquids or gases. It features a slender, tapered plunger that resembles a needle, which is screwed and unscrewed to control the flow. The design allows for fine adjustments, making needle valves ideal for applications that require precision flow regulation. They are typically used in applications where the flow needs to be carefully monitored and adjusted, such as in laboratory equipment, instrumentation, and various industrial processes.

The Importance of Stainless Steel

The term SS stands for stainless steel, a material renowned for its corrosion resistance, strength, and durability. Stainless steel is particularly important in the manufacturing of needle valves for several reasons

1. Corrosion Resistance Stainless steel is highly resistant to rust and corrosion, making it suitable for applications where the valve may be exposed to moist or aggressive environments. This feature is crucial in industries such as chemical processing, pharmaceuticals, and food and beverage, where valve contamination can lead to serious issues.

2. Durability SS needle valves are built to withstand high pressures and temperatures, ensuring reliability in demanding environments. The robust nature of stainless steel reduces the likelihood of valve failure, which can lead to unexpected downtime and costly repairs.

3. Cleanliness Stainless steel is easy to clean and maintains its structural integrity even after extensive use. This property is essential in sanitary applications, where hygiene is critical.

Advantages of SS Needle Valves

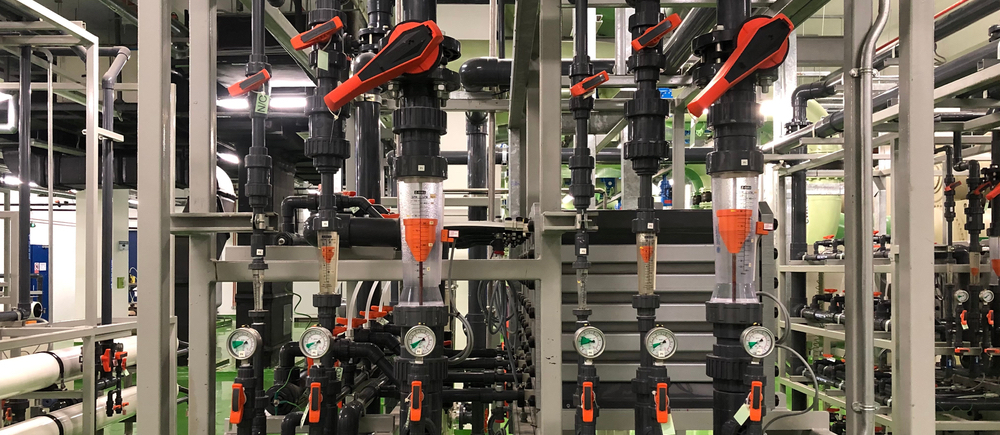

ss needle valves

1. Precision Control The design of needle valves allows for very fine adjustments to flow rates, making them ideal for applications that require exact measurements. This level of control is essential in laboratory settings and high-precision industrial applications.

2. Compact Design SS needle valves typically have a compact design, allowing them to fit into limited spaces within piping systems. This feature is beneficial in applications where space is at a premium.

3. Diverse Applications The versatility of SS needle valves means they can be used across a wide range of industries, including oil and gas, water treatment, pharmaceuticals, and HVAC systems. Their ability to handle different fluids and gases makes them invaluable in many processes.

4. Minimal Leakage When properly installed and maintained, SS needle valves provide minimal leakage, which is critical in processes where even a small spill can result in substantial losses or hazards.

Applications of SS Needle Valves

Due to their unique characteristics, SS needle valves find applications in numerous fields

- Chemical Processing They regulate the flow of corrosive chemicals and provide fine control necessary for chemical reactions. - Oil and Gas Used in pipeline systems to control the flow of crude oil and natural gas, SS needle valves ensure safe and efficient operations. - Laboratories Essential in scientific research to control gases and liquids precisely. - Pharmaceuticals Used in drug manufacturing processes where contamination can compromise product quality.

Conclusion

SS needle valves are crucial components in the realm of fluid control, offering a combination of durability, precision, and versatility. Their corrosion-resistant properties and ability to handle high-pressure situations make them indispensable across various industries. Whether in a laboratory, oil and gas sector, or chemical processing plant, the effective operation of an SS needle valve can significantly enhance system performance and reliability. As industries continue to evolve, the demand for precise control solutions like SS needle valves will undoubtedly remain strong.

-

3 types of check valves maintenance tipsNewsAug.23,2025

-

Ball valves types with trunnion mounted designNewsAug.23,2025

-

Butterfly valve company production capabilitiesNewsAug.23,2025

-

Fisher globe valve technical specificationsNewsAug.23,2025

-

Types of gaskets for flanges selection guideNewsAug.23,2025

-

Wedge gate valve suppliers quality standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025